![[NASA Logo]](../Images/nasaball.gif)

![[NASA Logo]](../Images/nasaball.gif) |

NASA Procedures and Guidelines |

This Document is Obsolete and Is No Longer Used.

|

|

P.1 Purpose

P.2 Applicability

P.3 Authority

P.4 References

P.5 Cancellation

2.1 General Program Support

2.2 Health Promotion and Wellness Programs

2.3 Quality Assurance Program

2.4 Records Management

3.1 Clinical Services

3.2 Physical Examinations

3.3 Emergency Services

3.4 Infection Control Program

4.1 Regulatory Compliance

4.2 Occupational Exposure Assessment and Management

4.3 Occupational Exposure Limits

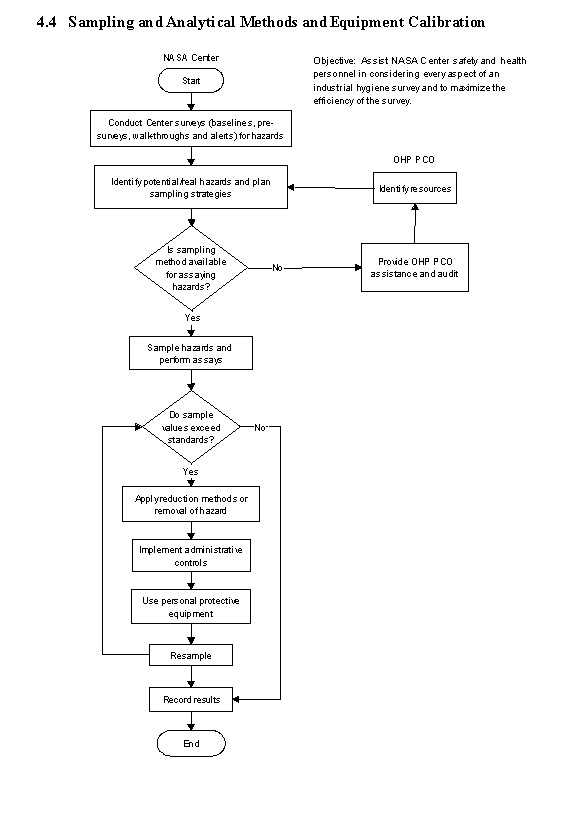

4.4 Sampling and Analytical Methods and Equipment Calibration

4.5 Ergonomics

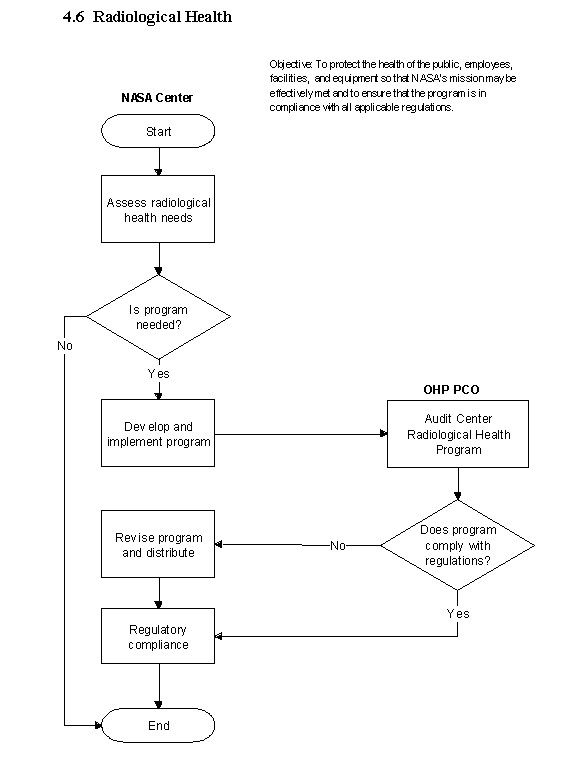

4.6 Radiological Health

4.7 Environmental Sanitation

4.8 Balancing Work-Rest Cycles

4.9 Hearing Conservation

4.10 Food Safety

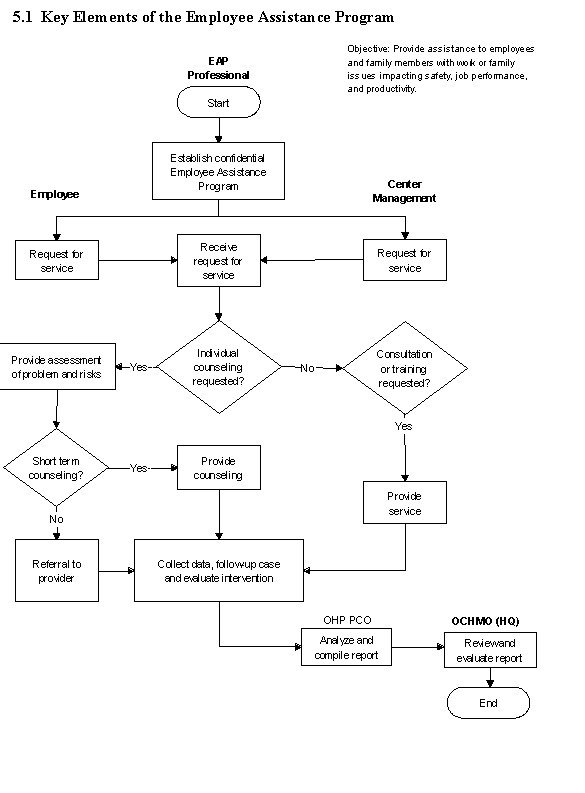

5.1 Key Elements of the Employee Assistance Program

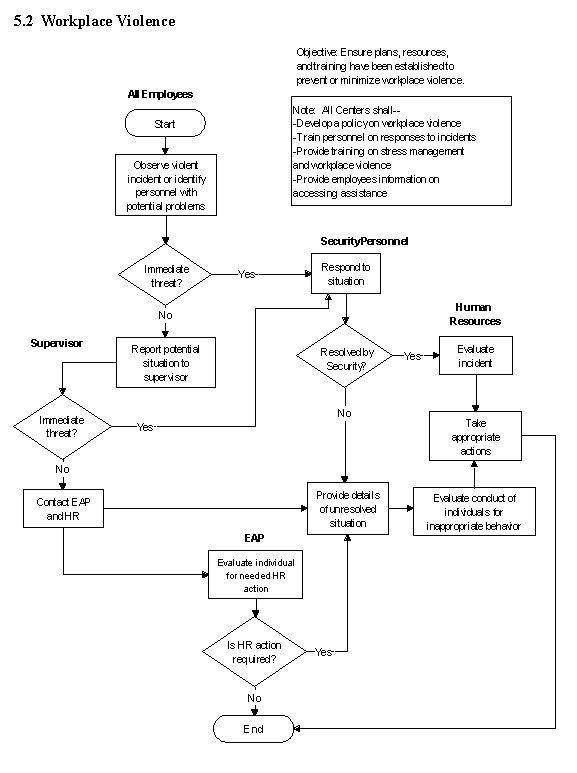

5.2 Workplace Violence

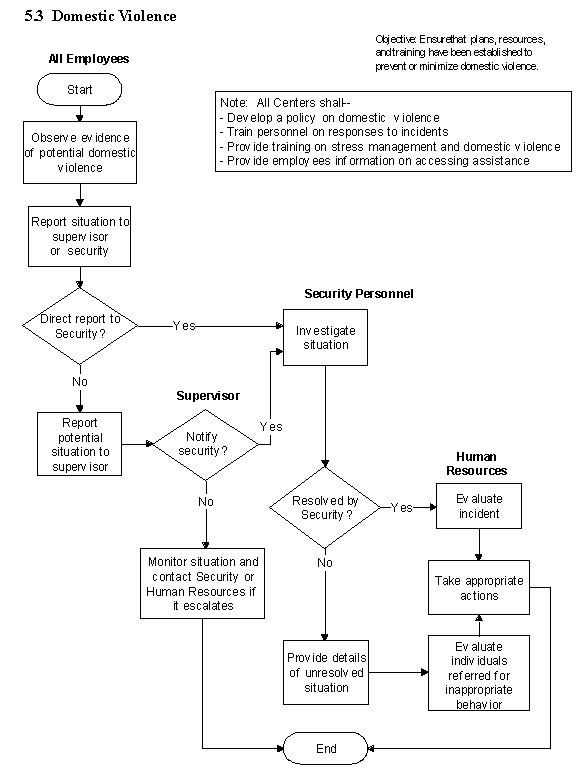

5.3 Domestic Violence

6.1 Management of Workers' Compensation Injuries and

Illnesses

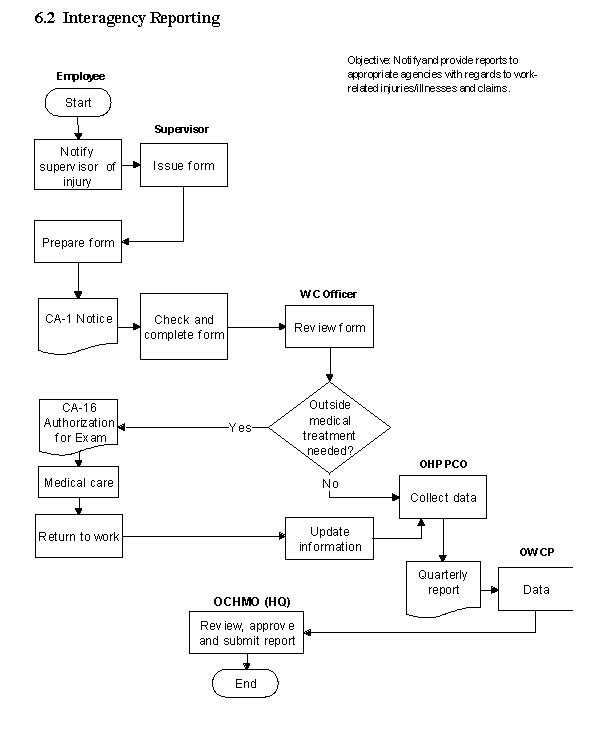

6.2 Interagency Reporting

7.1 Introduction

7.2 Purpose

7.3 Process Description

7.4 Responsibilities

7.5 References

This NASA Procedural Requirements (NPR) describes processes for implementing and managing the NASA Occupational Health Program (OHP). The OHP is the overreaching Agency function encompassing two major components (Occupational Medicine and Environmental Health) and integrating other essential contributors to employee health. This NPR explains how services and reporting procedures for occupational medicine, occupational health nursing, environmental health, and employee support elements are standardized, when warranted and practicable, across the Agency.

This NPG is applicable to NASA Headquarters, NASA Centers and Component Facilities as well as to the Jet Propulsion Laboratory (JPL)and NASA contractors to the extent specified in their contracts.

The authority for this NPG is as follows:

a. 42 U.S.C. 2473(c)(1) of the National Aeronautics and Space Act of 1958, as amended.

b. U.S.C. 668, Section 19,of the Occupational Safety and Health Act of 1970, as amended.

c. Executive Order 12196, dated February 26, 1980, "Occupational Safety and Health Programs for Federal Employees," (3 Code of Federal Regulations (CFR) 1980 Compilation).

d. Basic Program Elements for Federal Employee Occupational Safety and Health Programs and Related Matters, 29 C.F.R. ºº 1960.1 - 1960.90.

a. NPD 1800.2, NASA Occupational Health Program, January 16, 2001

b. NPD 1810.2, NASA Occupational Medicine Program, January 16, 2001

c. NPD 1820.1, NASA Environmental Health Program, January 16, 2001

d. NPD 1830.1, NASA Employee Assistance Program, January 16, 2001

e. NPD 1840.1, NASA Workers' Compensation Program, February 23, 2001

NPR 1800.1, NASA Occupational Health Program Procedures, dated October 16, 2002.

NPR 1820.1, Hearing Conservation, dated March 2, 2001

1.1 This NASA Occupational Health Program (OHP) Guideline was prepared to assist OHP professionals and allied professionals throughout the Agency in their daily tasks to assure the health of employees and a safe work environment. The scope and quality of services provided by OHP personnel at NASA Centers are instrumental in achieving the goal of maintaining optimal health and well-being of the Agency's workforce.

1.2 The elements of the OHP are Occupational Medicine, Environmental Health, Radiological Health or Health Physics, and programs for Health Promotion and Wellness, Workers' Compensation and Employee Assistance.

1.3 The format for the NPR focuses on essential processes and includes descriptions, responsibilities, and flowcharts that illustrate how processes are implemented. Additional reference materials are cited, when applicable. As an NPR, it is distributed and approved through NODIS.

1.4 The NASA Headquarters Office of the Chief Health and Medical Officer (OCHMO) issues policy directives for program activities through NPD's, advocates for program support, provides program resources, and monitors the progress of NPD's and NPR's during the NODIS review process.

1.5 The OHP Office is responsible for the accuracy of the content of the handbook and welcomes critical comments for improvements or suggestions for additions.

1.6 Contact the NASA OHP through the OHP Web site at http://ohp.nasa.gov, the NASA Occupational Health Program Manager, or each center's Medical Director

2.1.1 Technical Support Services

2.1.1.1 Introduction

a. NASA stresses the importance of promoting and maintaining physical and mental well-being of employees, to implement all program components in the best possible manner and to ensure compliance with regulatory requirements. The OHP seeks to preserve and maintain the Agency's invaluable human resources and assures the goal of allowing every employee the opportunity to work in a place free from recognized health hazards.

b. As an aid to reaching this goal, one of the responsibilities of the OHP as stated in NPD 1800.2, NASA Occupational Health Program, is to provide technical support to the OHP personnel at NASA Centers. Support may be given in a variety of forms, including but not limited to the following:

(1) Maintain a current, central registry of all applicable legal and regulatory requirements.

(2) Provide professional consultations for civil service and contractor occupational health personnel.

(3) Provide and/or procure technical reference materials.

(4) Provide and facilitate avenues of communication for the OHP community to share ideas and information.

(5) Collect and disseminate state-of-the-art information.

2.1.1.2 Responsibilities

a. NASA Center personnel are responsible for assessing needs to determine if assistance from the OHP is necessary and submitting requests for support.

b. NASA OHP personnel are responsible for providing technical expertise in OHP disciplines and identifying the need for specific technical support. They also provide audits and additional information necessary to evaluate requests that assist Centers in meeting program goals.

c. Reserved.

2.1.1.3 Process Description

a. Reserved.

b. NASA Center-Initiated Request

(1) Identify the need for specific technical support.

(2) Contact OHP and request technical support.

(3) OHP evaluates request and determines course of action.

(4) Provide additional information if necessary.

(5) Reserved.

(6) Reserved.

c. OHP-Initiated Support

(1) Identify specific technical support need through communication with NASA Centers during the audit process, program evaluation, working group meetings, or other contact.

(2) Perform evaluation to determine if specific support is an Agencywide or Center-specific need and gather additional data from NASA Centers as necessary.

(3) Develop plans for the procurement (if necessary), dissemination, and distribution of specific support to the NASA Centers. The plans also include provisions to confirm receipt and utilization by the NASA Centers and, if possible, appropriate and meaningful metrics associated with implementation and use.

2.1.1.4 Flow Diagram

The flow diagram for this process is shown in Figure 2.1.1 at the end of this section.

2.1.2 Reserved.

2.1.2.1 Reserved.

2.1.2.2 Reserved.

a. Reserved.

b. Reserved.

2.1.2.3 Reserved.

a. Reserved.

b. Reserved.

c. Reserved.

d. Reserved.

(1) Reserved

(2) Reserved

(3) Reserved

(4) Reserved

(5) Reserved

(6) Reserved

(7) Reserved

(8) Reserved

2.1.2.4 Best Practices

a. The OHP researches and obtains internal and/or external best practices to complement or augment services provided by OHP personnel at the NASA Centers.

b. Implementation

(1) Discrete mechanisms which aid implementation are as follows:

(a) OHP Web-site capability, allowing e-mail to be sent to all Agency OHP personnel.

(b) OHP Web-site provision of training on discipline specific topics and links to other sites for training and education.

(c) Occupational Health e-mail discussion group.

(d) Distribution lists for e-mail that display pertinent information dealing with work experience information.

(e) Teleconferencing.

(f) Video Teleconferencing System (ViTS).

(g)Periodic conferences and meetings.

(2) Reserved.

(3) Reserved.

2.1.2.5 Flow Diagram

The flow diagram for this process is shown in Figure 2.1.2 at the end of this section.

2.1.3 Education and Training of Occupational Health Professionals

2.1.3.1. Introduction

a. To meet its goals and fulfill its mission, the NASA OHP must have and retain knowledgeable and competent professionals. This requires that NASA Center OHP personnel possess basic knowledge, credentials, licensing and skills relevant to their designated health professional position. These OHP professionals have an obligation to keep up to date on advances in their field. In addition, NASA policy states that its health professional teams must pursue excellence by maintaining awareness of the most current knowledge and processes related to all disciplines required at NASA Centers. For these reasons OHP professionals must have access to all the training needed to reach their full potential.

b. It is also required that all current professional licensures, certifications, and accreditations necessary for professional operations be maintained. Maintaining required licensure and certifications dictates certain continuing education requirements for health professionals.

2.1.3.2 Responsibilities

a. NASA Center Directors are responsible for implementing and operating occupational health programs in full compliance with NPD 1800.2, NASA Occupational Health Program. This includes establishing effective organizations to fulfill occupational health requirements using professionally qualified persons and allocating resources for the HP.

b. Reserved.

c. The OHP works with NASA Headquarters and the NASA Centers to determine the most appropriate education and training opportunities to be provided each year.

2.1.3.3 Process Description

a. NASA installation hiring policies must comply with Federal and NASA requirements for professional education standards and where applicable, with State licensure statutes.

b. NASA Center OHP managers conduct assessments of professional and career development needs to determine the training needs of their staff.These needs are communicated to Center management and the OHP. Maximum use of telecommunication technologies assures the most efficient educational opportunities and resources.

c. Reserved.

(1) Reserved

(2) Reserved

(3) Reserved

(4) Reserved

(5) Reserved

d. To implement NASA policy in professional education and training, the OHP encourages and contributes to several forms of in-house training programs.These include, but are not limited to the following:

(1) Assuring availability of the most current and authoritative written reference materials.

(2) Providing ready access to the Internet (and specifically to the National Library of Medicine's search sources), the OHP Web site, and to intercenter and external consultants.

(3) Providing regular live and taped audio and video training courses.

(4) Conducting an annual Occupational Health Conference covering all OHP disciplines.

(5) Promoting intercenter and external events (courses, workshops, seminars) on essential topics by discipline experts.

(6) Conducting hands-on training in procedures and simulation exercises to refresh and augment skills where handling of actual events is infrequent.

Employees are able to receive specialized training in discipline-specific topics, as well as earn continuing education credits in occupational medicine, occupational health nursing, environmental health, and employee support programs. The key in-house training opportunity for health professionals is the NASA Occupational Health Conference. Discipline- specific conferences, such as those for environmental health and employee assistance programs, are also provided depending on employee availability and needs documented throughout the year. Satellite downlink broadcasts are also provided to employees when relevant topics become available.

e. Key steps the OHP uses in designing, implementing, and modifying a training and career development program are as follows:

(1) Perform a needs assessment for the institution.

(2) Customize the needs to the institution commensurate with budgetary limitations and available training time.

(3) Establish clear training and career development objectives.

(4) Establish clear performance criteria.

(5) Reserved.

(6) Reserved.

(7) Make modifications to the training program based on the results.

(8) Measure performance to goals.

f. Feedback to the OHP on availability and efficacy of current, and on anticipated benefit from planned, educational programs is routinely sought. From identified Center needs, the OHP determines which opportunities shall be offered, both new and repeated content.

2.1.3.4 Reference

NASA OHP Web site athttp://ohp.nasa.gov/topics/training

2.1.3.5 Flow Diagram

The flow diagram for this process is shown in Figure 2.1.3 at the end of this section.

2.1.4 Web Site Initiatives and Capabilities

2.1.4.1 Introduction

a. The NASA OHP Web site, located at http://ohp.nasa.gov, is the primary resource for quick dissemination of information to NASA OHP personnel. It assists in meeting the primary responsibilities of the OHP to NASA Centers.It serves as a repository of information for OHP personnel to utilize in performing their jobs. It also serves the NASA workforce, both civil service and contractor, and the general public.

b. The OHP Web site provides ongoing technical support to the NASA Centers, such as the following:

(1) Occupational Health Program Directories.

(2) Policies and Standards.

(3) Occupational Health Disciplines (Employee Assistance, Environmental Health, Occupational Medicine, Physical Fitness, and Workers' Compensation).

(4) Occupational Health Topics.

(5) Employee Health Information.

(6) Training Programs.

(7) Occupational Health Program Handbook Desktop Resources.

(8) Resources.

2.1.4.2 Responsibilities

a. OHP personnel at NASA Headquarters and NASA Centers evaluate the contents and make recommendations for changes when necessary.

b. The OHP is responsible for managing the OHP Web site and ensuring that current information is available for use by all OHP personnel.

2.1.4.3. Process Description

The NASA OHP Web site is an ongoing process of the NASA OHP. The goal is to increase employee knowledge and facilitate communication among the NASA OHP personnel. Specific actions for achieving this goal are as follows:

a. Review current Web site.

b. Review current NASA OHP priorities with NASA Headquarters and all NASA Centers.

c. Request changes, if necessary, to the NASA OHP Web site.

d. Regularly update the OHP Web site.

2.1.4.4 References

The OHP Desktop Resources, a new addition to the OHP Web site, is a dynamic element which provides inter-Center communications, additional up-to-date reference materials supporting topics in the handbook, new or revised drafts of documents in the review process for comments and suggestions, general information on topics of interest to the Centers, and formats and forms for obtaining audit and other types of data required for Agency reports.

2.1.4.5 Flow Diagram

The flow diagram for this process is shown in Figure 2.1.4 at the end of this section.

2.2.1 Fitness Centers

2.2.1.1 Introduction

a. As seen in the publication of the 1996 Report of the U.S. Surgeon General on physical activity and health, physical activity is at the top of our national public health agenda. Today, nearly one fourth of adult Americans have some form of cardiovascular disease. One of the major risk factors of cardiovascular disease is physical inactivity. The objective is to reduce cardiovascular disease by promoting regular exercise. To encourage physical activity in employees, on-site fitness facilities should be established and maintained, or membership in a local fitness center should be offered to employees. The fitness center should consist of shower facilities, an exercise room for stretching and classes, a walking/jogging trail, and a variety of indoor equipment such as treadmills,stair climbers, strength training machines, and free weights. Fitness machines should be equipped or devices should be readily available to monitor heart rate and blood pressure while exercising.

b.One of the OHP goals is to minimize sick absences and reduced productivity due to marginal physical disability, permanent disability, or premature death. This shall be accomplished by providing to employees physical fitness programs to help control and reduce health risk factors, such as sedentary lifestyle, obesity, high blood pressure, and diabetes.

2.2.1.2 Responsibilities

a. The fitness center personnel involved in management or delivery of exercise programs are responsible for obtaining formal training and must have required experience as established by the American College of Sports Medicine (ACSM) to ensure that clients are provided with safe, effective programs and services. Personnel should include the manager, fitness director, and fitness professionals. All personnel shall maintain Cardiopulmonary Resuscitation (CPR)/ Basic Life Support (BLS) certification and be trained in the Bloodborne Pathogen standard

b. The manager is responsible for the overall management of the facility and should be proficient in business, as well as design and delivery of exercise programs. This function is also responsible for fitness environment safety, emergency procedures, and ensuring that members and staff have received a health screening.

c. The fitness director function is responsible for program design, ensuring training, and staff supervision and accreditation, while managing the facility's exercise and activity programs. A degree in exercise science or another health-related field with at least 1 year of supervisory experience in the fitness industry is required. This position also requires professional certification at an advanced level by a nationally recognized health/fitness organization comparable to the ACSM health fitness instructor certification.

d. The fitness professional provides instruction to individuals in exercise and behavioral skills and should have a degree in exercise science. A professional certification from a nationally recognized health/fitness organization (comparable to ACSM exercise leader certification) is also preferred.

e.Facilities providing services in allied health fields such as nutrition or physical therapy should be certified, licensed, or registered with the State as required by law. In order to keep up to date with the most current information, all degreed professionals should attend professional development courses or conferences.

2.2.1.3 Process Description

a. The ACSM and the American Heart Association (AHA) recommends that all facilities offering exercise equipment or services should conduct cardiovascular screening of allnew members. The Physical Activity Readiness Questionnaire and the questionnaire developed by the Wisconsin Affiliate of the AHA are examples of screening instruments. The purpose of doing screenings prior to using the fitness facility is to identify individuals at risk for a cardiovascular incident while exercising. In addition to the questionnaire, blood pressure should also be evaluated. If any question suggests a potential medical problem such as recent or chronic illness or injury, or the blood pressure is 140/90 or higher, the individual shall be referred to either the Occupational Health clinic or their Private Medical Doctor (PMD) for counseling.>Regardless,and a written medical clearance prior to their use of the facility is required. Continued use of the fitness facility is established through renewal of the clearance process on a periodic basis. The results of the information should be kept on file and positively identifiable with the facility user.

b. For safety reasons unsupervised fitness facilities should not operate. It is recommended that all staff be well qualified and appropriately trained. If there are any unsupervised facilities not under contract or sponsored by NASA Centers, users of the facility must have identification on their person and signs must be displayed prominently, advocating a buddy system, and prompting users about medical problems such as chest pain, dizziness, bone or joint problems, and advising users with any of these symptoms to seek doctor's advice. The design of such a facility shall meet ACSM standards for an unsupervised facility. Use of a facility by any employee without someone else available to assist shall be discontinued.

c. A method should be enforced to identify (badge, keyed lock) members who have been screened and eligible to utilize the facility. Individuals are required to at least sign in each time they use the fitness center, or ideally through a computerized system in which statistical information could be extracted to monitor improvement and use. The hours of operation should be able to meet the majority of employees' needs and work schedules. Supervisors should encourage and support participation and the use of flextime work schedules in order to accommodate use of the fitness facility by employees throughout the day. Health observances such as the Health and Safety Day and National Employee Health and Fitness Day should be incorporated into the fitness center and health promotion activities at each Center. A mechanism for customer feedback should also be in place such as an annual survey for continued quality improvement.

d. All fitness facilities must have written emergency policies and procedures. A physician, registered nurse, or emergency medical technician trained in advanced cardiac life support is recommended to be a medical liaison responsible for critiquing emergency drills and reviewing medical emergency plans and incident reports. All fitness center staff should be certified in CPR and first aid prior to employment. A first aid kit containing bandages, gloves and a pocket mask shall be available to the staff for emergency use. Automatic External Defibrillator (AED) availability and training shall meet any Federal or State requirements. Staff training shall be done as soon as possible after employment with emergency drills practiced once every three months. Transportation of employees to a hospital and telephone access to 911 or the local emergency medical system identified on the telephone must be addressed in the emergency plan. A hard-wired system with a large visible emergency button to call medical, first aid, and security and prominently displayed sign is strongly encouraged. A staff member should remain with the employee at all times. Emergency policies and procedures that are regularly reviewed and practiced by the fitness center staff will optimize prompt emergency care to the employee.

2.2.1.4 References

a.NPD 1810.2A, NASA Occupational Medicine Program.

b. AHA/ACSM Scientific Statement, "Recommendations for Cardiovascular Screening, Staffing, and Emergency Policies at Health/Fitness Facilities." 1998.

2.2.1.5 Flow Diagram

The flow diagram for this process is shown in Figure 2.2.1 at the end of this section.

2.2.2 Health and Wellness Programs

2.2.2.1 Introduction

NASA Center health and wellness programs, including extensive stress management programs support the Agency's commitment to the health of its workforce. Health and wellness programs are designed on three levels. These levels include awareness and education, life-style behavioral change, and a supportive environment.

2.2.2.2 Responsibilities

a. NASA Center OHP personnel are responsible for assessing, planning, implementing and evaluating health promotion programs based on the needs of the Center.

b. The NASA OHP provides support and guidance to the Centers on health and wellness initiatives.

2.2.2.3 Process Description

a. An assessment of the Centers' health promotion needs, based on demographics and risk factors, is completed.

b. An annual health promotion plan is developed based on the needs assessment and the available resources. When possible, health promotion initiatives are coordinated with national holiday observances.

c. Plans are implemented and data collected for each event.

d. The health promotion plan and data are evaluated. Evaluations include participation rates, abnormal findings and referrals, customer satisfaction, and changes in health status and health behaviors.

2.2.2.4 Flow Diagram

The flow diagram of this process is shown in Figure 2.2.2 at the end of this section.

2.2.3 Nutrition in the Workplace

2.2.3.1 Introduction

a. Nutrition plays a major role in employee health and well-being. The goal is to increase awareness, knowledge, and create an environment in the workplace for NASA employees that support good health practices.

b. Creating an environment within the Centers that supports good health practices and good nutrition is important in improving employee health and well-being.

2.2.3.2 Responsibilities.

a. NASA Center Medical Directors are responsible for ensuring the implementation of nutritional awareness and education programs as well as advocating for environmental support in the workplace with the food service vendor.

b. The NASA OHP provides guidance and technical support for promoting nutrition at the NASA Centers. Technical support includes assistance to NASA Centers in providing employees with proper diet information, in the dietary control of diabetes, hypertension, and lipid disorders, and in the planning of cafeteria menu choices.

2.2.3.3 Process Description

a. Program Implementation

(1) Three levels of health promotion activities are recommended for implementing programs at NASA Centers. The first level is to increase awareness within the workforce of the impact nutrition has in maintaining good health and preventing disease. Secondly, provide Center employees with health education opportunities related to good nutrition that may result in behavioral changes. The final level is to encourage an environment that emphasizes good health practices by providing healthy food selections in cafeterias and vending machines.

(2) Formation of a Center employee committee to support health promotion activities should include representatives from different employee groups, including management and union personnel and the vendor contractor manager. The committee is responsible for tailoring health promotion activities to Center needs. It should develop a plan that includes program goals and objectives, planned activities, promotion strategies, an implementation schedule and metrics to be collected for program evaluation.

b. Environmental Support.

(1) Environmental support creates the structure needed for maintaining behavioral changes by ensuring the availability of healthy choices in the cafeteria and vending machines.

(2) Occupational Health Program staff can facilitate potential environmental changes with the contractor by working with the Food Service Vendor Contracting Officer.

(3) Food Service Contract Requirements

(a) Identify and provide a variety of low-fat, low-sodium, and high-fiber healthy choices in the cafeteria.

(b) Offer healthy choices for catered meetings or Agency sponsored events.

(c) Offer one healthy hot entre with a total fat content of less than 30 percent of total calories, saturated fat of less than 8-10 percent of calories, cholesterol of le , ss tha n , 150 milligrams, and sodium of less than 1000 milligrams.

(d) Provide nutritional labeling at the point of service for all hot entr?e selections including the total calories, percent of calories from fat, total fat, total saturated fat, and cholesterol.

(e) Label low-fat and high-fiber selections offered at salad, soup, and sandwich bars at the point of choice.

(f) Utilize products certified as Heart Healthy by the AHA.

(g) Modify recipes to lower content of total overall and saturated fat, cholesterol, and sodium.

(h) Modify food preparation by using cooking methods that do not add fat, e.g., baking, broiling, and boiling, trimming fat from meat, removing skin from poultry, and minimizing the use of gravy and sauces.

(i) Promote selection of healthy food choices by using a theme such as "Healthy Heart," "Just For You" or other nutritional campaigns.

(j) Post a permanent display of nutrition information including the Food Pyramid and Dietary Guidelines for Americans.

(k) Offer low-calorie, low-fat, and high-fiber snacks in the Centers' vending machines.

(4) Program Evaluation

Evaluating the impact of health promotion programs within the Agency is an essential component of a program. The short- and long-term program goals should be established in the planning stage.

2.2.3.4 References

a. NASA OHP Web site at http://ohp.nasa.gov/topics/nutrition

b. NASA Technical Bulletin "Promoting Nutrition in NASA Centers."

2.2.3.5Flow Diagram

The flow diagram for this process is shown in Figure 2.2.3 at the end of this section.

2.2.4 Solar Safe Program

2.2.4.1 Introduction

The Solar Safe Program is a preventive health initiative developed to address the risks associated with the development of skin cancer.

2.2.4.2 Responsibilities

a. The NASA OHP is responsible for providing health promotion materials, collecting Agency metrics and offering technical support. The OHP provides ongoing support with dermatology education programs, and screening and referral criteria.

b. The NASA Center Medical Directors are responsible for the implementation of the program. All NASA Centers must provide skin cancer screening as part of their medical services and cancer screening efforts.

2.2.4.3 Process Description

a. Reserved.

b. Reserved.

c. The program components implemented at the Centers are as follows:

(1) Administrative measures such as work schedule changes to reduce the amount and duration of exposure by limiting peak exposure between 10 a.m. and 2 p.m., thereby decreasing the potential risk of developing skin cancer.

(2) Health education and promotion activities to increase the awareness of potential risks associated with exposure to the Sun, employee education and prevention.

(3) Skin cancer screening and detection is offered to the NASA workforce in the form of general population screenings as a component of periodic physicals and medical surveillance exams.

(4) Protective measures include the use of personal protective gear such as hats and making sunscreen products available to reduce Sun exposure, ultraviolet sensor cards to increase employee awareness of harmful radiation and quantify exposure level for skin block protection.

d. Reserved.

2.2.4.4 References

a. NASA Technical Bulletin "Promoting NASA's Skin Cancer Prevention Program 'Solar Safe."

b. NASA OHP Web site at http://ohp.nasa.gov/topics/skin cancer

2.2.4.5 Flow Diagram

The flow diagram for this process is shown in Figure 2.2.4 at the end of this section.

2.2.5 Smoking Cessation

2.2.5.1 Introduction

a. Reserved.

b. The NASA OHP promotes smoking cessation using standard procedures across the NASA Centers to identify smokers, to assess smokers' interest in quitting smoking, and to provide useful smoking cessation information regarding available programs.

2.2.5.2 Responsibilities

a. NASA Center OHP health care professionals are responsible for establishing a smoking cessation program utilizing personnel from various occupational health disciplines and notifying the OHP that Center needs are met by locally available programs or that assistance is required.

b. The OHP supports ongoing efforts at NASA Centers to reduce the number of employees who smoke. It is responsible for providing information on how successful smoking cessation programs are established and maintained to NASA Center OHP health care professionals.

2.2.5.3 Process Description

a. Center health care professionals provide periodic assessments to the OHP on the progress and outcomes of the program, which are reflected in Agencywide assessments.

b. The OHP provides information on smoking cessation programs to health care professionals at NASA Centers to encourage them to establish or improve smoking cessation programs.

2.2.5.4 References

a. Executive Order 13058, Protecting Federal Employees and the Public From Exposure to Tobacco Smoke in the Federal Workplace, August 9, 1997.

b. Agency for Health Care Policy and Research, Clinical Practice Guideline No. 18, b.Smoking Cessation, 1996.

c. Public Health Service, Healthy People 2000: Mid

2.3.1 Credentialing and Privileging of Health Care Professionals

2.3.1.1 Introduction

a. The Credentials verification and privileging of health care staff is necessary both for ensuring the safety of employees and study volunteers and for delivery of quality health care. To facilitate NASA Center Occupational Health Program managers in performing these functions, the has developed a checklist that Occupational Health personnel may use to accomplish the task. The checklist is shown in Appendix B.

b. Several factors converge to direct that health care systems assure the existence of authentic practice credentials and proper privileging of health care professionals. The credentials verification process helps assure that the provider, in whose hands patients entrust their health and wellness, possesses current knowledge and appropriate skills. Privileging identifies and authorizes conduct of those procedural tasks for which providers must possess adequate skills in order to perform their responsibilities. Continuing education, relevant training, and skills utilization help to maintain competence, continuous improvement in efficiency, and effectiveness of health care. The use of credentialing and privileging augments the caliber of health care while minimizing the risk of untoward events. With these measures operative, NASA demonstrates its commitment to excellence, to employees, and to sustained high quality of health care.

c. Paramount in the processes of credentials and privileging are uniformly applied criteria for appointment, maintenance, and retention of currently knowledgeable, experienced, and competent health care professionals. Besides verifying essential information from authenticated primary sources, this will also require some degree of adaptation and customization to the many health care activities implemented at each NASA Center .

d. NASA credentialing and/or privileging criteria will be required of all licensed professionals involved in health care or human research by NASA or under contract to NASA, whether located physically on site at a Center or externally. Health care delivery will be interpreted as the supervision of, monitoring of, or direct delivery of health care to NASA astronauts, the employees, employee family members, visitors (in an emergency), or test/research volunteers. Such personnel include licensed independent practitioners (allopathic and osteopathic physicians, licensed psychologists who provide services without direction or supervision) and supervised health care providers (physician assistants, nurse practitioners, nurses). This system and these criteria have clear policies and procedures and well-defined roles and responsibilities for all participants . For the purpose of credentials verification, three levels of Health Care will be recognized are as follows:

(1) Supervision or research monitoring in a nondirect patient care role will require credentials verification and in some cases privileging,

(2) Direct patient/client care, counseling, or direct research monitoring will require both credentials verification and privileging, and

(3) Nonlicensed, supervised health care providers will require privileging for specific functions.

e. These stipulations do not apply to personnel at noncontract off-site facilities to which employee patients may be referred.

2.3.1.2 Responsibilities

a. Credentialing is managed by the CHMO. Center Chief Medical Officers/Medical Directors will implement these criteria for all civil service health care professionals and, together with technical and contracting personnel, assure that the same criteria are stipulated and affected for health care providers in all contracts procuring health care or human research services. The above are also responsible to ensure availability of adequate resources of time and training to maintain required licensure, certification, and privileges.

< processes. privileging and credentials Agency??s the with compliance assure to assess periodically implementation, their oversee guidelines, Agency promulgate establish will OHP NASA??s>

2.3.1.3 Process Description

a. Basic standards for the process are derived from the standards applied to hospitals and ambulatory health care facilities. The following four core criteria are :

(1) Current licensure.

(2) Relevant education, training, and/or experience.

(3) Current competence.

(4) Evidence suggesting the ability to perform requested privileges.

b. Information necessary to support items (1) and (2) will be obtained from primary sources, in written, signed documents, and in advance of appointment. Where telephonic or electronic means are employed to acquire information, explicit written verification of the source will be provided.

c. Upon request, NASA may privilege incumbent practitioners, who do not meet explicit credentials criteria, on the basis of their record of experience in a particular setting and of demonstrated proficiency in the procedure for which privilege is requested (grand-fathering). Each case will be considered individually and decided by peer representatives and if it involves licensed independent practitioners, the decision will be made through the Medical Policy Board.

d. Providers in advisory, supervisory, or research monitoring functions - in a nondirect care role - requiring a licensed health care professional (e.g., physician, nurse, dietitian) who may also be called upon to assist in an emergency.

(1) Shall provide evidence of the following credentials: Proof of professional education,evidence of specialty training, board certification if applicable and licensure to practice in a U.S. State or Territory.

(2) Shall maintain training in Basic Life Support (BLS) and the use of Automated External Defibrillator (AED).

(3) Shall meet other specific privileging or certification required by the assigned function.

(4) If functioning as a Medical Review Officer for NASA, shall be certified by a national certifying agency - American Association of Medical Review Officers (AAMRO) or American College of Occupational and Environmental Medicine (ACOEM).

e. Providers - in a direct care role - in health care delivery, counseling, or direct human research monitoring functions requiring a licensed health care professional (e.g., physician, psychologist, nurse) who are likely to be called upon to assist in an emergency are as follows:

(1) Shall provide evidence of the following credentials. Proof of professional education, evidence of specialty training, board certification if applicable, and licensure to practice in a U.S. State or Territory.

(2) Shall maintain certification in Advanced Cardiac Life Support (ACLS) and defibrillator use (AED and the specific defibrillator(s) in their care location).

(3) Shall meet other specific privileging or certification required by the assigned function (e.g., Medical Review Officer, sigmoidoscopy, conduct/monitoring of stress tests).

f. All supervised and non-licensed health care staff, such as clinic, emergency, or laboratory support personnel, on Earth or in space, performing or supporting procedures (e.g., electrocardiogram interpretation, audiological interpretation, pulmonary function testing) for which privileging must be granted in order to function in a direct-patient care setting are as follows:

(1) Shall be trained in BLS.

(2) May be required to obtain organizational "Certification" or "Licensing" after training in assigned procedures or functions for certain privileging (e.g., audiometric testing, X-ray technician functions, Breath Alcohol Testing (BAT)).

g. The complexities involved in Workers' Compensation Program cases may mandate specific training in this discipline; some States require certification (e.g., Florida ) to work in this arena. To assure competence and uniformity in managing these cases, credentials and privileging must be instituted.

h. Current competence will be attested by signed letters of informed opinion from specialty certification boards, peers of personal acquaintance, medical supervisors, academic program directors, or by demonstrated competency. These attestations will describe the applicant's clinical performance, clinical judgment, and technical skills (including operative procedures), discharge of professional obligations, and ethical demeanor. A search for any history of medical malpractice and of criminal record will be included, including a query of the National Practitioner's Data Bank.

i. Privileges will be delineated and granted in accordance with documented professional competence and facility support capability provided. The process will emphasize scrutiny and thoroughness prior to appointment. Continuous improvement of existing professional competence and of services offered will be sought. Where unacceptable performance must be confronted, the process will be fully documented and a fair hearing and redress assured with adverse decisions.

j. All credentials and credentialing information are subject to strict individual confidentiality. In the case of contractors, records of individual credentials verification and list of privileges shall be maintained by the hiring organization. Additionally a similar record shall be kept at the practicing organization with postings of relevant licensures at the practicing facility. All records containing credentialing information will be maintained in accordance with 5 U.S.C. 552a, the Privacy Act of 1974, as amended.

k. In the case of civil service personnel, records of individual credentials verification and list of privileges shall be maintained by the Office of the Chief Health and Medical Officer.

- References

a. The Credentialing Resource Center, Division of HCPro, Marblehead, MA.

b. 2000-2001 Comprehensive Accreditation Manual for Ambulatory Care, HR 7, JCAHO, Oakbrook Terrace, IL.

c. The National Committee for Quality Assurance (NCQA), Washington, DC.

d. The Credentials and Privileges Manual, The US Air Force, DoD, Washington, DC.

e. Procurement Notice, PN-97-58, NASA, Washington, DC.

f. NPD 8900.1E, Medical Policy Board.

2.3.1.5 Flow Diagram

The flow diagram for this process is shown in Figure 2.3.1 at the end of this section.

2.3.2 Peer Review

2.3.2.1 Introduction

a. Peer review is an important component of the quality process. The peer-review process evaluates the quality of care provided against established criteria based on standards and regulatory requirements. This process assists in the assessment of the competency of the healthcare professional and monitors treatment trends and outcomes. Results of the peer-review process provide valuable information and a critical link to the Quality Improvement and Risk- Management programs.

b. Standards of Care describe specific diagnostic or therapeutic maneuvers that should or should not be performed in certain clinical circumstances.

2.3.2.2 Responsibilities

a. The Center Medical Director is responsible for providing the resources and establishing the process for peer review at the NASA Centers.

b. The NASA OHP is responsible for establishing and maintaining the Agency guidelines on peer review. The NASA OHP conducts periodic audits of the peer- review process at the Center level.

2.3.2.3 Process

a. Elements of the process are outlined below.

b. Develop and implement an ongoing peer review process at each Center. The process ensures that the following recordkeeping requirements and established standards of care are met:

(1) Assigning and giving authority to personnel for the review process.

(2) Developing procedures for the peer review process.

(3) Conducting a review of medical records and assessing each one for completeness, timeliness, appropriateness of medical treatment and continuity of care.

(4) Collecting and evaluating data for trends and outcomes.

(5) Providing input to Quality Improvement and or Risk-Management personnel.

c . Require peer competency for the credentialing process that is based on information regarding the healthcare professionals clinical performance and skills and interpersonal relationships with peers and patients.

2.3.2.4 Flow Diagram

The flow diagram for this process is shown in Figure 2.3.2 at the end of this section.

2.3.3 Quality Improvement

2.3.3.1 Introduction

a. The NASA OHP is committed to continuous process improvements in the delivery of health services to civil service personnel, contractors, and visitors. The quality improvement process provides ongoing opportunities to improve processes, the quality of health care provided, and resolve problems. The evaluation process considers the administrative, clinical cost and patient outcomes with a focus on efficacy, effectiveness, and appropriateness of care and customer satisfaction. As a component of the Quality Assurance Program the quality improvement process is linked with the risk management and peer-review process.

b. Several terms used in describing quality improvement need to be defined. These include the following:

(1) Quality Improvement - An approach to the continuous study and improvement of the processes of providing health care services to meet the needs of individuals and others.

(2) Quality Assurance - The formal and systematic exercise of identifying problems in medical care delivery, designing activities to overcome these problems, and carrying out followup steps to ensure that no new problems have been introduced and that corrective actions have been effective.

(3) Standards of Care - Specific diagnostic or therapeutic maneuvers that either should or should not be performed in certain clinical circumstances.

2.3.3.2 Responsibilities

a. The Medical Director at each NASA Center is responsible for implementation and management of a quality improvement program.

b. The NASA OHP is responsible for establishing policy and guidelines for quality improvement.

2.3.3.3 Process Description:

Elements of the process include the following:

a. Developing a quality improvement plan as part of the overall Quality Assurance Program at each Center.

b. Assigning responsibility for the quality improvement process.

c. Reviewing recommendations for quality improvements received from risk management and peer review.

d. Defining the scope of care for the occupational health program.

e. Identifying quality care indicators such as patient satisfaction and outcomes of care.

f. Collecting, organizing and analyzing data.

g. Recommending and implementing actions to improve care.

h. Assessing the effectiveness of the actions and documenting improvement.

i. Communicating results to the staff.

2.3.3.4 Flow Diagram

The flow diagram for this process is shown in Figure 2.3.3 at the end of this section.

2.3.4 Reliability-Centered Maintenance

2.3.4.1 Introduction

a. The purpose of reliability-centered maintenance is to identify maintenance tasks to be performed periodically to sustain the maximum level of reliability and safety of the product and prevent downtime caused by unscheduled maintenance. The goal is to maintain a high state of readiness, and it is initiated as part of product design and development. The manufacturer normally provides a predetermined maintenance schedule. Most of the improvements for operational Occupational Health products occur in safety and operational reliability.

b. Reliability is the likelihood that a piece of equipment is in adequate condition to carry out its intended functions and that it will not experience failure during a given period.

c. Key equipment includes emergency equipment (e.g., AED, other defribrillators, respirators), all vital equipment for OSHA compliance (e.g., samplers, pulmonary function testers), high-value equipment (e.g., x-ray units, electrocardiographic equipment), and equipment necessary to maintain normal operations in accordance with the Safe Medical Device Act.

2.3.4.2 Responsibilities

Center Medical Directors are responsible for the development of Reliability-Centered Maintenance programs specifically for medical equipment (e.g., crash carts and defibrillators).

2.3.4.3 Process Description

a. Elements of the process include the following:

(1) Develop a maintainability program plan that is used to collect maintenance information on all key equipment in one location. The information can be in a tabular or outline format if applicable.

(2) Equipment section list s key equipment to be covered and identifiers such as the date of manufacture (if available from the equipment) and the model number.

(3) Reference section includes new information or alerts from the manufacturer or regulatory agency and includes location of any other equipment information such as manuals, circuit diagrams, specifications.

(4) Technical communication section includes the manufacturer and manufacturer contact number and Center equipment maintenance contact number.

(5) The maintenance concept section includes the basic maintenance requirements and organizational responsibility . This area should include period of equipment test (daily, weekly, yearly), who should perform the test or maintenance, the criteria for a successful test, and who should review any deviation from a normal result.

(6) Policy and procedure section outlines the actions to be taken if a deviation from normal occurs but does not duplicate test/maintenance procedures available in the equipment manual.

(7) The organizational interface section addresses the lines of communication among the operational organization, the maintainability organization, and any other organization involved.

(8) Update and resolve equipment problems and keep maintenance history for inclusion in the Reference section . Maintenance personnel contact with the manufacturer can obtain information on updated maintenance and test procedures, history of any product or component recalls, and perhaps reliability information and from periodic company maintenance, such as the top three components most frequently replaced and average time of replacement.

b. Information in history should include event, date of discovery, safety risk (none, low, medium, or high), downtime and action required.

c. Pro vide lessons learned concerning any new safety or reliability information to NASA and to the office responsible for maintaining Center Lessons.

2.3.4.4 Flow Diagram

The flow diagram for this process is shown in Figure 2.3.4 at the end of this section.

2.3.5 Risk Management

2.3.5.1 Introduction

a. The Occupational Health Risk Management Program seeks to identify, evaluate and control exposures to eliminate and/or minimize the potential for liability. Effective risk-management programs at each NASA Center help to reduce the potential risk of injury to civil service personnel, contractors and visitors as well as maintain public confidence for the Agency. Risk management activities include administrative and clinical aspects of the NASA OHP. The risk-management activities and feedback are linked in the con , tinuous Qualit y Improvement , p rocess.

b. Several terms used in risk management need to be defined. They include the following:

(1) Risk Management - The identification, evaluation and reduction of risk of injury follows the ASI Safety and Health Hierarchy which prioritizes safety efforts for the public, astronauts, pilots, NASA workforce, and high-value equipment and property.

(2) Sentinel Event - An unexpected occurrence or variation involving death or serious physical or psychological injury, or the risk thereof.

(3) Root Cause Analysis - A process for identifying the basic or causal factor(s) that underlie variation in performance, including the occurrence or possible occurrence of a Sentinel Event.

2.3.5.2 Responsibilities

a. Center Directors are responsible for ensuring the development and management of a Centerwide Risk-Management Program. The Center's risk based acquisition management program may require technical consultation from medical, radiological health, and environmental/industrial health in addition to Safety, security, and export control input.

b. Center Medical Directors are responsible for the development and management of the medical portion of the center's Risk-Management Program.

c. Center Environmental Health Managers are responsible for the development and management of the environmental health portion of the center's Risk Management Program.

d. The NASA OHP is responsible for establishing guidelines for OHP risk management and periodically auditing the program in place at each Center.

2.3.5.3 Process Description

- Elements of the process include the following:

(1) Assigning an individual or a committee to be responsible for the program.

(2) Developing a risk-management program at each NASA Center .

(3) Ensuring adequate coverage during and after normal clinic hours.

(4) Conducting regular audits.

- Ensuring effective risk management by reviewing program components such as the following:

(1) Data trends.

(2) Complaints.

(3) Incidents.

(4) Deaths, trauma, or adverse events.

(5) Staffing levels, skill mix, and education.

c. Ensuring orientation for new staff members that includes reviewing current trends, means of minimizing risk and quality improvement initiatives.

d. Providing education on risk-management activities to all staff.

e. Reviewing any Sentinel Event, conducting analysis of the root cause, and recommending corrective action.

f. Managing incident reporting.

g. Providing recommendations to Quality Improvement.

h. Ensuring that both health a nd safety issues are addressed and coordinated.

- References

a. NPR 7120.5A, NASA Program and Project Management P roce sses and Requirements, April 3, 1998 .

b. NPR 8715.3, NASA Safety Manual, January 24, 2000.

c. Procurement Notice 97-58, Risk Management, November 22, 2000.

2.3.5.5 Flow Diagram:

The flow diagram for this process is shown in Figure 2.3.5 at the end of this section.

2.3.6 Standardization of Contract Specifications

2.3.6.1 Introduction

a. The NASA OHP recognizes that each NA SA Center manages its occupational health programs differently. At some Centers, the environmental health function may be completely performed by NASA personnel while other Centers may have this function outsourced to a contractor. The occupa tional medicine function at most NASA Centers is provided by contractor and managed by NASA personnel. Outsourcing of this function has resulted in the establishment of stand-alone contracts at the individual Centers that do not provide continuity or equality of services across the Agency. The NASA OHP examined support contracts from several Centers and adopted the best elements of each contract for inclusion in one document.

b. This document is available as a reference guide to Center personnel who are preparing the requirements for environmental health and occupational medicine support contracts at the Centers. This document does not supersede or impose new requirements for contracts but only serves as a guideline for developing and documenting requirements. It may initiate the development of contract equality and services across the Agency.

2.3.6.2 Responsibilities

a. The NASA Centers are responsible for ensuring that their environmental health and occupational medicine personnel are equipped with resources necessary to perform their jobs in an effective manner.

b. The NASA OHP is responsible for revising this document and continually updating the Web-based desktop guide to ensure that it is current with new regulations or significant issues and incorporates suggested improvements from Agency or Center management.

2.3.6.3 Process Description

a. The specific areas covered for environmental health are as follows:

(1) Establishing industrial hygiene program services.

(2) Establishing health physics program services.

(3) Establishing environmental sanitation program services.

(4) Maintaining a material safety data sheet program.

(5) Supporting emergency response teams.

(6) Acquiring laboratory accreditation.

(7) Managing an asbestos abatement program.

(8) Qualifying for or acquiring personnel licensure, certification, training, and experience.

b. The specific areas covered for occupational medicine are as follows:

(1) Providing emergency medical services.

(2) Defining staff positions, duties, and required qualifications.

(3) Establishing hours of operations.

(4) Establishing the scope of services required.

(5) Defining health maintenance examination requirements.

(6) Maintaining medical records.

(7) Maintaining an EAP.

(8) Defining report requirements.

(9) Managing health promotion activities.

(10) Providing medical consultation.

(11) Maintaining a health fitness center.

(12) Providing medical advice to committees and programs.

(13) Maintaining medical equipment and supplies.

- References

a. NASA OHP Web site - http://ohp.nasa.gov/, for standardized contract specifications.

b. Department of Defense (DOD) Standardization Program - http://www.dsp.dla.mil/, for standardization of contracts.

c. Procurement Notice 97-58, Risk Management, November 22, 2000.

d. Ames Research Center Statement of Work for Emergency Medical Services and Occupational Health (No. 2-35338, January 26, 1993).

e. Dryden Flight Research Center Statement of Work for Occupational Health Services (NAS2-14002, April 4, 1994).

f. Glenn Research Center Statement of Work for Environmental Health Services.

g. Glenn Research Center , Lewis Field, Performance Work Statement for Health Screening Program, Physical Fitness Program, and Occupational Medicine Program (May 2, 2000).

h. NASA Headquarters Statement of Work for Comprehensive Occupational Health Program.

i. Jet Propulsion Laboratory Charter for Occupational Health Services - Section 1980 and Statement of Work for Occupational Health Services (NAS&-1260, February 1997).

j. Johnson Space Center Statement of Work for Environmental Health & Occupational Medicine Services.

k. Kennedy Space Center Statement of Work for Environmental Health & Occupational Medicine Services.

l. Kennedy Space Center Statement of Work for Medical and Environmental Services (NAS10-99001).

m. Langley Research Center Statements of Work for Environmental Health Services and for Industrial Hygiene Services.

n. Marshall Space Flight Center Performance Work Statement for Environmental Health and Occupational Medicine Services (NAS8-97321).

2.3.6.5 Flow Diagram

The flow diagram for this process is shown in Figure 2.3.6 at the end of this section.

2.3.7 Occupational and Environmental Health Programs Performance Assessment

2.3.7.1 Introduction

The NASA OHP is committed to providing its employees with a safe and healthy workplace. To ensure that this commitment is implemented, the OHP has developed an audit process for the environmental health and occupational medicine program to ensure a successful effort.

2.3.7.2 Responsibilities

a. NASA Center personnel are responsible for implementing both environmental health and occupational medicine programs at their Centers.

b. The NASA OHP is responsible for assessing the effectiveness of the Agency's environmental health and occupational medicine programs at NASA Centers. To carry out this responsibility, it conducts continuous improvement audits of NASA Centers' environmental health and occupational medicine programs on a rotating basis or when specifically requested by an individual Center.

2.3.7.3 Process Description

a. The continuous improvement audit process involves examining a variety of environmental health and occupational medicine processes at NASA Centers.

b. Examples of the environmental health elements of this process are as follows:

(1) Management Leadership and Employee Involvement

(2) Management Leadership

(3) Employee Participation

(4) Implementation

(6) Contractor Safety and Health

c. Workplace Analysis

d. Health Hazard Prevention and Control

(1) Health Hazard Prevention and Control

(2) Health Hazard Control

(3) Medical Program

- Emergency Environmental Health Response

- Environmental Health Training

g. Examples of the occupational medicine elements of this process are as follows:

(1) Medical

(2) Center Demographics

(3) Employee Rights and Organizational Ethics

(4) Quality of Care

(5) Center Health Promotion and Wellness

(6) Organizational Performance

(7) Leadership

(8) Management of Human Resources

(9) Management of Information

(10) Surveillance, Prevention, and Control of Infection

(11) Management of the Medical Care Environment

h. Workers' Compensation

- Fitness Program and Facility

- Employee Assistance Program

k. When the OHP conducts an assessment, the necessary personnel, documentation, and resources are made available to the team of visitors. The OHP provides an exit briefing for Center personnel before leaving, and a written report of its findings is submitted to Center personnel within a few weeks after the visit.

2.3.7.4 Flow Diagram

The flow diagram for this process is shown in Figure 2.3.7 at the end of this section.

2.3.8 Safety and Health Certification and Approval Programs

2.3.8.1 Introduction

a. OSHA has developed voluntary guidelines on the management of safety and health programs. The International Organization for Standardization (ISO) has also developed a standard on environmental management (ISO 14001) and plans to publish a standard on occupational safety and health management (ISO 18000). Both systems are based on the concept of managing occupational safety and health protection of workers and the environment rather than just attempting to comply with Government standards.

b. Both of these programs are similar in approach. They examine the same program elements and also produce a similar goal of recognition of exemplary safety and health programs. However, there has been a delay with the finalized development and release of the ISO 18000 standard. It is, therefore, recommended that if a NASA Center is going to pursue the implementation of an occupational safety and health management system, the established OSHA guidelines should be utilized. If the ISO 18000 certification is required by the NASA Center when the standard is eventually published, the task will be made easier by already having an established occupational safety and health management system in place. Based upon these reasons, the rest of this section focuses on OSHA Voluntary Protection Program (VPP).

c. The VPP provides a venue for establishing a cooperative agreement among management, labor, and OSHA. From this agreement, a proactive approach to the management of safety and health issues is achieved, and benefits, such as reduced injury and illness rates, decreased insurance premiums, and increased quality, productivity and employee morale, can be realized. The Agency fully supports the adoption and implementation of these procedures at its Centers.

- Responsibilities

a. The NASA Center is responsible for implementing the requirements of the guidelines and for providing any additional funding required to support this program effort.

b. The OHP OCP is responsible for providing assistance to the NASA Centers with their approval efforts. Assistance may include application review, on-site readiness reviews, coordination with certifying agencies and lending/providing of subject reference material to the Centers' implementation team.

- Process Description

a. The VPP has three program levels of achievement which include the following:

(1) Star, the highest level of achievement which denotes a site that is not only successful in implementing a comprehensive safety and health program but one that also goes beyond compliance and strives for a leadership role.

(2) Merit, the recognition granted for sites that have demonstrated both the desire and the ability to meet the requirements of Star but have not quite achieved it.

(3) Demonstration the recognition given to sites that are unique situations not covered by Star requirements, such as nuclear power plants. OSHA will examine four areas of a site's safety and health program during a site visit. They are as follows:

(a) Management leadership and employee involvement.

(b) Worksite analysis.

(c) Hazard prevention and control.

(d) Safety and health training.

b. During a site visit, OSHA will not only be looking for evidence of documented programs, but also, and most importantly, subjective evidence that the programs are implemented. Employee involvement in the VPP effort is critical, and at most successful Star sites, the entire effort is run by employees with site safety and health personnel acting as consultants to the effort.

c. The time required for a facility or NASA Center to become certified varies from as little as 6 months to 2 years and is largely determined by the quality of existing programs and the commitment of both Senior Management and the employees.

2.3.8.4 References

OSHA website at http://www.osha.gov/oshprogs/vpp

2.3.8.5 Flow Diagram

The flow diagram for this process is shown in Figure 2.3.8 at the end of this section.

2.3.9 Environment of Care

2.3.9.1 Introduction

a. The NASA OHP is committed to ensuring the delivery of quality health services at NASA Center Occupational Health clinics. In order to facilitate this philosophy, the has developed a checklist that Occupational Health personnel may use to gauge the current status of their clinical facilities against Joint Commission on Accreditation of Health Care Organizations (JCAHO) Environment of Care (EOC) guidelines. The checklist is shown in Appendix C.

b. The goal of the Environment of Care process is to provide a safe, functional, supportive, and effective environment for patients, staff members, and other individuals in the clinic. This is crucial to providing quality patient care and achieving good outcomes. Achieving this goal depends on performing the following:

(1) Strategic and ongoing master planning by management for space, clear circulation of occupants, equipment, supportive environment, and resources needed to safely and effectively support the services provided.

(2) Educating staff about the role of the environment in safely, sensitively, and effectively supporting patient care.

(3) Developing standards to measure staff and clinic performance in managing and improving the environment of care.

(4) Implementing plans to create and manage the health unit's environment of care.

2.3.9.2 Responsibilities

Each NASA Center is responsible for the overall safety of its facilities including on-site occupational health clinics. In support of this task, the OHP offers this document to Center personnel who wish to assess their clinic's facilities against JCAHO criteria. The checklist is voluntary and not all inclusive of all JCAHO guidelines. If a Center wishes to pursue formal accreditation, it is advisable to consult the complete JACHO accreditation criteria.

2.3.9.3 Process Description

a. "Environment of Care" refers to a variety of "key elements and issues" that contribute in creating the way the space feels and works for people, patients, visitors, and staff experiencing the clinics healthcare delivery system. Certain key elements and issues that can be significant in their ability to positively influence patient outcomes and satisfaction are as follows:

(1) Light (both natural and artificial).

(2) Orientation and access to nature and the outside.

(3) Clarity of access (both exterior and interior circulation).

(4) Physical cues to navigating through the inside and around the outside of the clinic.

(5) Control.

(6) Privacy (visual, auditory, and document).

(7) Order.

(8) Space size and configuration appropriate and consistent with the clinical philosophy.

(9) Color compatability.

(10) Security assurance.

(11) Convenient patient flow and efficient layouts that support staffing and overall functional operation.

b. These elements when appropriately managed, create welcoming, comfortable environments that support and maintain patient dignity and allow ease of interaction, reduce stressors, and encourage patient/employee participation in the delivery of care. Additionally, by incorporating the management of these elements in standardized processes and procedures, the clinic's will realize the following:

(1) Reduced environmental hazards and risks.

(2) Reduced accidents and injuries.

(3) Safe conditions for patients, visitors and staff.

c. The checklist will examine the five functional areas that make up JCAHO's Environment of Care Guidelines.

d. Planning & Design

Compliance with the National Fire Protection Association (NFPA) Life-Safety Code is essential when constructing new or modifying existing facilities. This section of the checklist seeks to determine if the clinic's structure is built to code.

e. Implementation

According to the Environment of Care requirements, the clinic should have documented programs that address the following:

(1) Safety Management.

(2) Security Management.

(3) Hazardous Materials.

(4) Hazardous Waste.

(5) Emergency Preparedness.

(6) Life Safety Management.

(7) Medical Equipment.

(8) Utility Systems.

f. The checklist can identify program areas where clinic programs may be lacking.

g. Evaluation

This section focuses on the calibration and maintenance records of medical equipment and critical utility systems.

h. Orientation and Training

Environment of Care requirements specify that the clinic staff shall be educated about the role of the environment in safely and effectively supporting patient care. The education and training should include information about the physical characteristics and the processes for monitoring and reporting on the health care environment. This section of the checklist seeks to determine if this information is provided.

i. Environment

This section's goal is to give an appraisal of the tangible assets of the facility . Headings under this section include the following:

(1) Building and Grounds.

(2) Exiting.

(3) Emergency Power.

(4) Medical Gases.

(5) Central Gas Supply Systems.

(6) Compressed Air Systems.

(7) Central Vacuum Systems.

(8) Construction/Detail.

(9) Fire Protection/Life Safety.

j. Although the tried to be make this section as comprehensive as possible, differences in facilities, operations, geographic location and municipal/Center requirements, deviations may be necessary to effectively utilize this section. Note: Determinations on deviations from this section must be made by qualified personnel.

2.3.9.4 References

a. NASA Standard 8719.11, Safety Standard for Fire Protection.

b. NPR 8820.2c, Facility Project Implementation Handbook for Technical Guidance.

2.3.9.5 Flow Diagram

The flow diagram for this process is shown in Figure 2.3.9 at the end of this section.

2.4.1 Employee Medical Records

2.4.1.1 Introduction

a. An individual medical (health) record shall be established and maintained on every employee at the first encounter with an Occupational Health clinic. Medical records must be safeguarded, maintained and dispositioned in accordance with NPR 1441.1, NASA Records Retention Schedules. Such a record shall include any or all of the following:

(1) Reference and interim medical history and progress notes.

(2) Results of examinations by employee health staff.

(3) Treatments, medications, and immunizations prescribed or given.

(4) Medical consultations.

(5) Reports to and from physicians and other health care providers.

(6) Findings of fitness-for-duty examinations according to job requirements.

(7) Results of ret , urn-to-work examinations as required from hospitalizations of extended medical leave.

(8) Reports of job-related injury and illness.

(9) Occupational or accidental exposures and incidents.

(10) Environmental hazards/conditions of the work place related to health.

(11) Related laboratory test data.

(12) Biologic monitoring data.

(13) Required signed informed consents authorizing diagnostic and treatment procedures.

(14) Certain health related information obtained by questionnaire.

(15) Certain health insurance records.

(16) Specific job training completed.

b. Medical records require extreme care for their security and are subject to strictest confidentiality against unauthorized access or disclosure. Some types of health information must be disclosed by law. For example, Occupational Safety and Health Administration (OSHA) and Workers' Compensation (WC) require reporting of occupational injuries and illnesses. Sources of all information must be clearly identified by name, initials, or organization. Health records are never altered; when necessary, corrections are properly annotated, dated, initialed, and explanation given.

c. On the other hand, patient/employee access to their own health record is nearly always assured (except in certain situations; for example, psychiatric conditions, where an attending physician thinks knowledge of such information would prove detrimental to the patient's/employee's h , ealth).

d. Certain types of health-related information are so potentially vulnerable to misuse against patients/employees, e.g ., Employee Assistance Program (EAP) records, Human Immunodeficiency Virus (HIV) tests, that they must be kept in wholly separate record systems or coded to preclude direct identification with the patient/employee.

e. All records will be maintained in accordance with 5 U.S.C. 552a, the Privacy Act of 1974, as amended, and in accordance with the restrictions in the Health Information Management System (HIMS) in NASA's "Privacy Act; Annual Notice and Amendment to Systems of Records," published in the Federal Register.

2.4.1.2 Responsibilities

a. Each NASA Center Occupational Health Facility generates, maintains, and manages the employee health record. The record is subject to all provisions described above and any other legally valid determinations. The Center may not arbitrarily manage, disclose contents, or dispose of this record.

b. The Center Medical Director is responsible to ensure that Health Care Professional opinions provided by the health facility and required by regulations do not violate the employee's confidentiality . This responsibility also extends to ensuring confidential performance of drug, HIV, and bloodborne pathogen tests and that records are confidentially maintained, and any fax or electronic receipts of test results do not have public access. There is also responsibility to make records available for Quality Control review by the OHP when requested during a site audit.

c. The NASA OHP at least annually requires certain statistical information which must be derived from employee health and ancillary records . The may also access health records for purposes of quality assessment and planning towards practical uniformities and future automations. Patient confidentiality will always be maintained .

2.4.1.3 Process Description

a. The health record is one of the most diverse documents in common use today, from its content, its derivation, its form, and its organization. It is an absolute essential in the delivery of health care. And though it has universally recognizable elements, it follows no particular consistency in format. The health record continues to grow with little opportunity for compression.

b. To the extent that much of its content is not in digital computer convention, retrieval of some information may be cumbersome and slow. Moreover, since much of a medical record continues to be generated in handwritten format, readability (legibility) frequently suffers. These records are subject to random audit and should have periodic analysis for improving functionality as well as selected case review for enhancing the quality of health care delivered. The health record is really the major documentation of health care service rendered.

c. Because of the above and other concerns, the health record has been a prime target for some wholesale improvement with new concepts, technologies, and a substantial augmentation by automation. Structuring the retrieval by a problem-oriented record or computerization is strongly encouraged.

2.4.1.4 Flow Diagram