3.1.1

This chapter establishes the core set of common technical processes and requirements to be used by NASA projects in engineering system

products during applicable product-line life-cycle phases (see Figure 5-3) to meet phase exit criteria and project objectives. The 17

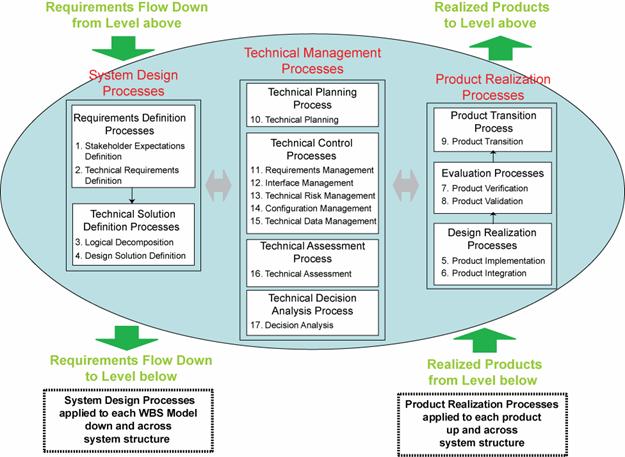

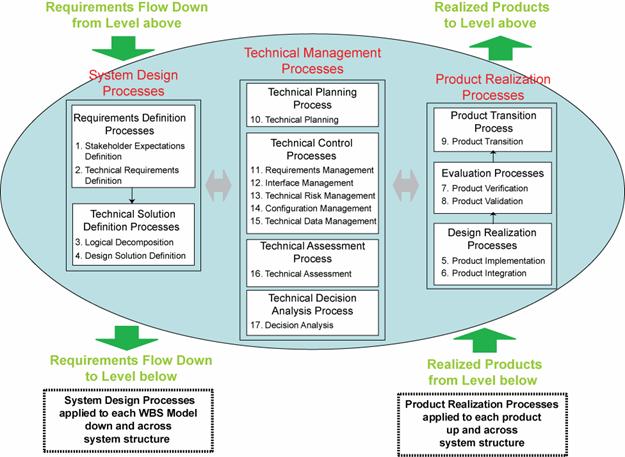

common technical processes are enumerated according to their description in this chapter and their interactions shown in Figure 3-1.

This SE common technical processes model illustrates the use of: (1) the system design processes for "top down" design of each product in

the system structure, (2) the product realization processes for "bottom up" realization of each product in the system structure, and (3)

the technical management processes for planning, assessing, and controlling the implementation of the system design and product realization

processes and to guide technical decisionmaking (decision analysis). The SE common technical processes model is referred to as an "SE

engine" in this SE NPR to stress that these common technical processes are used to drive the development of the system products and

associated work products required by management to satisfy the applicable product-line life-cycle phase exit criteria while meeting

stakeholder expectations within cost, schedule, and risk constraints.

Figure 3‑1 SE Engine

3.1.2

The context in which the common technical processes are used is provided below.

3.1.2.1

The common technical processes are applied to a product-based Work Breakdown Structure (WBS) model to concurrently develop the products

that will satisfy the operational or mission functions of the system (end products) and that will satisfy the life-cycle support functions

of the system (enabling products). The enabling products facilitate the activities of system design, product realization, operations and

mission support, sustainment, and end-of-product-life disposal or recycling by having the products and services available when needed.

3.1.2.2

The common technical processes are applied to design a system solution definition for each WBS model down and across each level of the

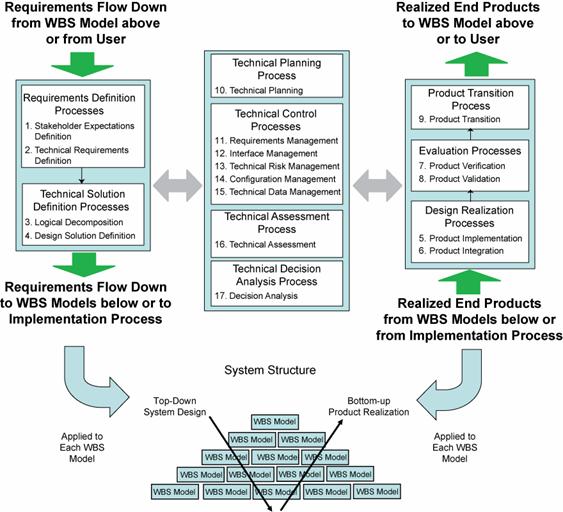

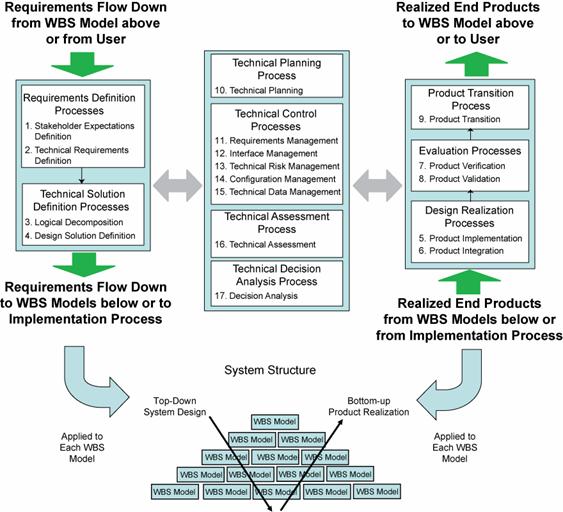

system structure and to realize the WBS model end products up and across the system structure. Figure 3-2 illustrates how the three major

sets of processes of the SE Engine (system design processes, product realization processes, and technical management processes)

are applied to a WBS model within a system structure (a hierarchy of product-based WBS models).

Figure 3-2 Application of SE Engine Processes within System Structure

3.1.2.3

The common technical processes are used to define the WBS models of the system structure in each applicable phase of the relevant

product-line life cycle (see Figure 5-3) to generate work products and system products needed to satisfy the exit criteria of the

applicable phase. System engineering continues well into the operations and maintenance phase of a project, i.e., after the system

products are delivered. For example, in the course of operating, maintaining, and disposing of an existing system, all upgrades,

enhancements, supporting or enabling developments, and reconfigurations must apply the common SE technical processes.

3.1.2.4

The common technical processes are applied by assigned technical teams and individuals of the NASA workforce trained in the

requirements of this SE NPR.

3.1.2.5

The assigned technical teams and individuals should use the appropriate and available sets of tools and methods to accomplish required

common technical process activities. This would include the use of modeling and simulation as applicable to the product-line phase,

location of the WBS model in the system structure, and the applicable phase exit criteria.

3.1.3

The assigned technical teams shall define in the project SEMP how the required 17 common technical processes,

as implemented by Center documentation, will be applied to the various levels of project WBS model system structure during each applicable

life-cycle phase and have their approach approved by the DGA.

For the statements below "establish" means developing policy, work instructions, or procedures to implement process activities.

"Maintain" includes planning the process, providing resources, assigning responsibilities, training people, managing configurations,

identifying and involving stakeholders, and monitoring and controlling the process.

3.2.1 Stakeholder Expectations Definition Process

3.2.1.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for the definition of stakeholder expectations for the applicable WBS model.

3.2.1.2

The stakeholder expectations definition process is used to elicit and define use cases, scenarios, operational concepts, and

stakeholder expectations for the applicable product-line life-cycle phases and WBS model. This includes requirements for: (a) operational

end products and life-cycle-enabling products of the WBS model; (b) expected skills and capabilities of operators or users; (c) expected

number of simultaneous users, (d) system and human performance criteria, (e) technical authority, standards, regulations, and laws; (f)

factors such as safety, quality, security, context of use by humans, reliability, availability, maintainability, electromagnetic

compatibility, interoperability, testability, transportability, supportability, usability, and disposability; and (g) local management

constraints on how work will be done (e.g., operating procedures). The baselined stakeholder expectations are used for validation of the

WBS model end product during product realization.

3.2.1.3

Typical practices of this process are defined in Appendix C.1.1.

3.2.2 Technical Requirements Definition Process

3.2.2.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for definition of the technical requirements from the set of agreed upon stakeholder expectations for the applicable WBS

model.

3.2.2.2

The technical requirements definition process is used to transform the baselined stakeholder expectations into unique, quantitative, and

measurable technical requirements expressed as "shall" statements that can be used for defining a design solution for the WBS model end

product and related enabling products.

3.2.2.3

Typical practices of this process are defined in Appendix C.1.2.

3.2.3 Logical Decomposition Process

3.2.3.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for logical decomposition of the validated technical requirements of the applicable WBS model.

3.2.3.2

The logical decomposition process is used to improve understanding of the defined technical requirements and the relationships among the

requirements (e.g., functional, behavioral, and temporal) and to transform the defined set of technical requirements into a set of

logical decomposition models and their associated set of derived technical requirements for input to the design solution definition process.

3.2.3.3

Typical practices of this process are defined in Appendix C.1.3.

3.2.4 Design Solution Definition Process

3.2.4.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for designing product solution definitions within the applicable WBS model that satisfy the derived technical requirements.

3.2.4.2

The design solution definition process is used to translate the outputs of the logical decomposition process into a design solution

definition that is in a form consistent with the product-line life-cycle phase and WBS model location in the system structure and that

will satisfy phase exit criteria. This includes transforming the defined logical decomposition models and their associated sets of

derived technical requirements into alternative solutions, then analyzing each alternative to be able to select a preferred alternative,

and fully defining that alternative into a final design solution definition that will satisfy the technical requirements. These design

solution definitions will be used for generating end products either by using the product implementation process or product integration

process as a function of the position of the WBS model in the system structure and whether there are additional subsystems of the end

product that need to be defined. The output definitions from the design solution (end product specifications) will be used for conducting

product verification.

3.2.4.3

Typical practices of this process are defined in Appendix C.1.4.

3.2.5 Product Implementation Process

3.2.5.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for implementation of a design solution definition by making, buying, or reusing an end product of the applicable WBS model.

3.2.5.2

The product implementation process is used to generate a specified product of a WBS model through buying, making, or reusing in a form

consistent with the product-line life-cycle phase exit criteria and that satisfies the design solution definition specified requirements

(e.g., drawings, specifications).

3.2.5.3

Typical practices of this process are defined in Appendix C.2.1

3.2.6 Product Integration Process

3.2.6.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation for the integration of lower level products into an end product of the applicable WBS model in accordance with its design

solution definition.

3.2.6.2

The product integration process is used to transform the design solution definition into the desired end product of the WBS model through

assembly and integration of lower level, validated end products in a form consistent with the product-line life-cycle phase exit

criteria and that satisfies the design solution definition requirements (e.g., drawings, specifications).

3.2.6.3

Typical practices of this process are defined in Appendix C.2.2.

3.2.7 Product Verification Process

3.2.7.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for verification of end products generated by the product implementation process or product integration process

against their design solution definitions.

3.2.7.2

The product verification process is used to demonstrate that an end product generated from product implementation or product integration

conforms to its design solution definition requirements as a function of the product-line life-cycle phase and the location of the WBS

model end product in the system structure. Special attention is given to demonstrating satisfaction of the measures of performance (MOPs)

defined for each measure of effectiveness (MOEs) during conduct of the technical requirements definition process.

3.2.7.3

Typical practices of this process are defined in Appendix C.2.3.

3.2.8 Product Validation Process

3.2.8.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for validation of end products generated by the product implementation process or product integration process against their

stakeholder expectations.

3.2.8.2

The product validation process is used to confirm that a verified end product generated by product implementation or product integration

fulfills (satisfies) its intended use when placed in its intended environment and to ensure that any anomalies discovered during validation

are appropriately resolved prior to delivery of the product (if validation is done by the supplier of the product) or prior to

integration with other products into a higher-level assembled product (if validation is done by the receiver of the product). The

validation is done against the set of baselined stakeholder expectations. Special attention should be given to demonstrating satisfaction

of the MOEs identified during conduct of the stakeholder expectations definition process. The type of product validation is a function of

the form of the product and product-line life-cycle phase and in accordance with an applicable customer agreement.

3.2.8.3

Typical practices of this process are defined in Appendix C.2.4.

3.2.9 Product Transition Process

3.2.9.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for transitioning end products to the next higher level WBS-model customer or user.

3.2.9.2

The product transition process is used to transition a verified and validated end product that has been generated by product

implementation or product integration to the customer at the next level in the system structure for integration into an end product or,

for the top level end product, transitioned to the intended end user. The form of the product transitioned will be a function of

the product-line life-cycle phase exit criteria and the location within the system structure of the WBS model in which the end product

exits.

3.2.9.3

Typical practices of this process are defined in Appendix C.2.5.

3.2.1 Technical Planning Process

3.2.10.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for planning the technical effort.

3.2.10.2

The technical planning process is used to plan for the application and management of each common technical process and to identify,

define, and plan the technical effort applicable to the product-line life-cycle phase for WBS model location within the system structure

and to meet project objectives and product-line life-cycle phase exit criteria. A key document generated by this process is the SEMP.

(See Chapter 6.)

3.2.10.3

Typical practices of this process are defined in Appendix C.3.1.

3.2.11 Requirements Management Process

3.2.11.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for management of requirements defined and baselined during the application of the system design processes.

3.2.11.2

The requirements management process is used to: (a) manage the product requirements identified, baselined, and used in the definition of

the WBS model products during system design; (b) provide bidirectional traceability back to the top WBS model requirements; and (c) manage

the changes to established requirement baselines over the life cycle of the system products.

3.2.11.3

Typical practices of this process are defined in Appendix C.3.2.

3.2.12 Interface Management Process

3.2.12.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for management of the interfaces defined and generated during the application of the system design processes.

3.2.12.2

The interface management process is used to: (a) establish and use formal interface management to assist in controlling system product

development efforts when the efforts are divided between Government programs, contractors, and/or geographically diverse technical teams

within the same program or project and (b) maintain interface definition and compliance among the end products and enabling products that

compose the system, as well as with other systems with which the end products and enabling products must interoperate.

3.2.12.3

Typical practices of this process are defined in Appendix C.3.3.

3.2.13 Technical Risk Management Process

3.2.13.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for management of the technical risk identified during the technical effort. (NPR 8000.4, Risk Management Procedural

Requirements, is to be used as a source document for defining this process, and NPR 8705.5, Probabilistic Risk Assessment (PRA)

Procedures for NASA Programs and Projects, provides one means of identifying and assessing technical risk.)

3.2.13.2

The technical risk management process is used to examine on a continuing basis the risks of technical deviations from the project plan and

identify potential technical problems before they occur so that risk-handling activities can be planned and invoked as needed across the

life of the product or project to mitigate impacts on achieving product-line life-cycle phase exit criteria and meeting technical

objectives.

3.2.13.3

Typical practices of this process are defined in Appendix C.3.4.

3.2.14 Configuration Management Process

3.2.14.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for configuration management.

3.2.14.2

The configuration management process for end products, enabling products, and other work products placed under configuration control is

used to: (a) identify the configuration of the product or work product at various points in time; (b) systematically control changes

to the configuration of the product or work product; (c) maintain the integrity and traceability of the configuration of the product

or work product throughout its life; and (d) preserve the records of the product or end product configuration throughout its life cycle,

dispositioning them in accordance with NPR 1441.1, NASA Records Retention Schedules.

3.2.14.3

Typical practices of this process are defined in Appendix C.3.5.

3.2.15 Technical Data Management Process

3.2.15.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for management of the technical data generated and used in the technical effort.

3.2.15.2

The technical data management process is used to: (a) provide the basis for identifying and controlling data requirements; (b)

responsively and economically acquire, access, and distribute data needed to develop, manage, operate, and support system products

over their product-line life; (c) manage and disposition data as records; (d) analyze data use; (e) if any of the technical effort

is performed by an external contractor, obtain technical data feedback for managing the contracted technical effort; and (f) assess the

collection of appropriate technical data and information.

3.2.15.3

Typical practices of this process are defined in Appendix C.3.6.

3.2.16 Technical Assessment Process

3.2.16.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for making assessments of the progress of planned technical effort and progress toward requirements satisfaction.

3.2.16.2

The technical assessment process is used to help monitor progress of the technical effort and provide status information for support of the

system design, product realization, and technical management processes.

3.2.16.3

Typical practices of this process are defined in Appendix C.3.7.

3.2.17 Decision Analysis Process

3.2.17.1

The Center Directors or designees shall establish and maintain a process to include activities, requirements, guidelines, and

documentation, for making technical decisions.

3.2.17.2

The decision analysis process, including data collection (e.g., engineering performance, quality, and reliability data), is used to help

evaluate technical decision issues, technical alternatives, and their uncertainties to support decisionmaking. This process is used

throughout technical management, system design, and product realization processes to evaluate the impact of decisions on performance,

cost, schedule, and technical risk.

3.2.17.3

Typical practices of this process are defined in Appendix C.3.8.

DISTRIBUTION:

NODIS

This Document is Obsolete and Is No Longer Used.

Check the NODIS Library to access the current version:

http://nodis3.gsfc.nasa.gov

![[NASA Logo]](../Images/nasaball.gif)