a. This

appendix contains best typical practices as extracted from industry and

national and international standards and as found within the Agency. The

practices may be used by Centers in preparing directives, policies, rules, work

instructions, and other documents implementing SE processes. The

practices of this appendix may also be used in the future assessments of those

plans and processes to provide feedback to the OCE and Centers on the strengths

and weaknesses in the Center's implementation of this SE NPR. These practices

can be expanded and updated as necessary.

b. Each process is

described in terms of purpose, inputs, outputs, and activities. Notes are

provided to further explain a process and to help understand the best practices

included. A descriptive figure is also provided for each process to

illustrate notional relationships between activities within a process and

the sources of inputs and destinations of outputs. Figures in this appendix are

not intended to include all possible inputs, outputs, or intermediate work

products.[2]

c. System Design Processes

a. There are four system design processes applied to each

product-based WBS model from the top to the bottom of the system

structure: (1) Stakeholder Expectation Definition, (2) Technical

Requirements Definition, (3) Logical Decomposition, and (4) Design

Solution Definition. (See Figure 3-2.)

b. During the application of these four processes to a WBS model

it is expected that there will be a need to apply activities from other

processes yet to be completed in this set of processes and to repeat process

activities already performed in order to arrive at an acceptable set of

requirements and solutions. There will also be a need to interact with the

technical management processes to aid in identifying and resolving issues

and making decisions between alternatives.

c. For software products, the technical team should refer to

NPR 7150.2 software design requirements. The technical team should also

ensure that the process implementations comply with NPR 7150.2 software

product realization requirements for software aspects of the system.

C.1.1 Stakeholder Expectations Definition Process

C.1.1.2 Inputs and Sources:

a. Customer expectations (from users and program and/or project)

b. Other stakeholder expectations (from project and/or other

interested parties of the WBS model products - recursive loop).

c. Customer flow-down

requirements from previous level WBS model products (from Design Solution

Definition Process - recursive loop - and Requirements Management and

Interface Management Processes)

C.1.1.3 Outputs and Destinations:

a. Set of validated stakeholder expectations, including interface

requirements (to Technical Requirements ;Definition, Requirements

Management, and Interface Management Processes).

b. Baseline operational concepts (to Technical

Requirements Definition Process and Configuration

Management Processes).

c. Baseline set of enabling product support strategies (to

Technical Requirements Definition Process and Configuration

Management Processes).

d. Measures of Effectiveness (MOEs) (to Technical

Requirements Definition Process and Technical Data Management

Process).

C.1.1.4 Activities

For the WBS model in the system structure, the following

activities are typically performed:

a. Establish a list that identifies customers and other

stakeholders that have an interest in the system and its products.

b. Elicit customer and other

stakeholder expectations (needs, wants, desires, capabilities,

external interfaces, and constraints) from the identified stakeholders.

c. Establish

operational concepts and support strategies based on

stakeholder expected use of the system products over the system's

life.

d. Define stakeholder expectations in acceptable statements that

are complete sentences and have the following characteristics: (1) individually

clear, correct, and feasible to satisfy; not stated as to how it is to be

satisfied; implementable; only one interpretation of meaning; one

actor-verb-object expectation; and can be validated at the level of the

system structure at which it is stated; and (2) in pairs or as a set there

is an absence of redundancy, consistency with respect to terms used, not in

conflict with one another, and do not contain stakeholder expectations of questionable

utility or which have an unacceptable risk of satisfaction.

e. Analyze

stakeholder expectation statements to establish a set of measures

(measures of effectiveness) by which overall system or product

effectiveness will be judged and customer satisfaction will be determined.

f. Validate that the resulting set of

stakeholder expectation statements are upward and downward traceable

to reflect the elicited set of stakeholder expectations and that any anomalies

identified are resolved.

g. Obtain

commitments from customer and other stakeholders that the resultant

set of stakeholder expectation statements is acceptable.

h. Baseline the

agreed to set of stakeholder expectation statements.

C.1.1.5 Process Flow Diagram

a. A typical process flow diagram for the stakeholder

expectations definition process is provided in Figure C-1 with inputs

and their sources and the outputs and their destinations. The

activities of the stakeholder expectations definition process are truncated

to indicate the action and object of the action.

b.The customer flow-down requirements from the design solution

definition process are applicable at levels of the system structure

below the top level. The other stakeholder expectations are applicable at each

level of the system structure to reflect the local management policies,

applicable standards and regulations, and enabling product support needs

for the lower level WBS model products.

Figure C-1 - Stakeholder Expectation Definition

Process

C.1.2 Technical

Requirements Definition Process

C.1.2.2 Inputs and Sources:

a. Baselined set of stakeholder expectations, including interface

requirements (from Stakeholder Expectations Definition and

Configuration Management Processes).

b.Baselined Concept of Operation (from

Stakeholder Expectations Definition and Configuration

Management Processes).

c. Baselined Enabling Product Support Strategies (from

Stakeholder Expectations Definition and Configuration

Management Processes).

d.Measures of Effectiveness (from

Stakeholder Expectations Definition and Technical Data

Management Processes).

C.1.2.3 Outputs and Destinations:

a. Set of validated technical requirements that represents a

reasonably complete description of the problem to be solved, including

interface requirements (to Logical Decomposition and Requirements and

Interface Management Processes).

b.Sets of MOPs that when met will satisfy the MOE to which a set

is related (to Logical Decomposition and Technical Data Management

Processes).

c. A set of critical technical performance measures (TPMs) that if not

met will put the project in cost, schedule or performance risk (to

Technical Assessment Process).

C.1.2.4 Activities

For the WBS model in the system structure, the following

activities are typically performed:

a. Analyze the scope of the technical problem to be solved to identify and

resolve the design boundary that identifies: (1) which system functions

are under design control and which are not; (2) expected interaction among

system functions (data flows, human responses, and behaviors); (3) external

physical and functional interfaces (mechanical, electrical, thermal, data,

procedural) with other systems; (4) required capacities of system products; (5)

timing of events, states, modes, and functions related to operational

scenarios; and (6) emerging or maturing technologies necessary to make

requirements.

b.Define

constraints affecting the design of the system or products or how the

system or products will be able to be used.

c. Define functional and behavioral expectations for the system or

product in acceptable technical terms for the range of anticipated uses of

system products as identified in the concept of operations. This permits

separation of defined stakeholder expectation functions and behaviors

that belong to a lower level in the system structure and to allocate them to

the appropriate level.

d.Define the

performance requirements associated with each defined functional and behavioral

expectation.

e. Define technical requirements in acceptable "shall" statements that

are complete sentences with a single "shall" per numbered statement and have

the following characteristics: (1) individually clear, correct, and feasible to

satisfy; not stated as to how it is to be satisfied; implementable; only one

interpretation of meaning; one actor-verb-object requirement; and can be

validated at the level of the system structure at which it is stated; and

(2) in pairs or as a set there is an absence of redundancy, consistent with

respect to terms used, not in conflict with one another, and form a set of

"design-to" requirements.

f.

Validate that the resulting technical requirement statements (1)

have bidirectional traceability to the

baselined stakeholder expectations; (2) were formed using valid

assumptions; and (3) are essential to and consistent with designing and

realizing the appropriate product solution form that will satisfy the

applicable product-line life-cycle phase exit criteria.

g. Define

MOPs for each identified measure of effectiveness (MOE) that cannot

be directly used as a design-to technical requirement.

h. Define

appropriate TPMs by which technical progress will be assessed.

i.

Establish the

technical requirements baseline.

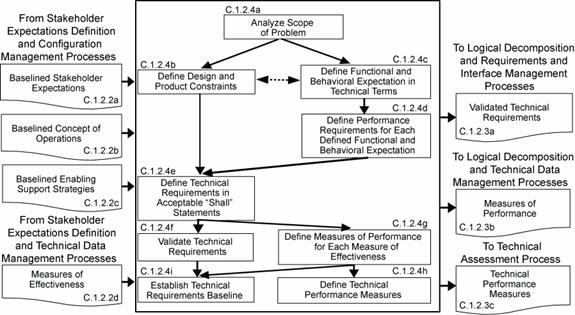

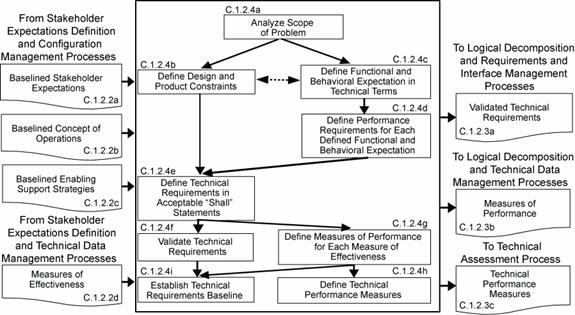

C.1.2.5 Process Flow Diagram

A typical process flow diagram for the technical

requirements definition process is provided in Figure C-2 with inputs and

their sources and the outputs and their destinations. The activities of the

technical requirements definition process are truncated to indicate the action

and object of the action.

Figure C-2 - Technical Requirements Definition Process

C.1.3 Logical

Decomposition Process

C.1.3.2 Inputs and Sources:

a. The baseline set of validated technical requirements, including

interface requirements (from Technical Requirements Definition and

Configuration Management Processes).

b.The defined MOPs (from Technical

Requirements Definition and Technical Data Management Processes).

C.1.3.3 Outputs and Destinations:

a. Set of validated derived technical requirements, including interface

requirements (to Design Solution Definition and Requirements and Interface

Management Processes).

b.The set of logical decomposition models (to Design Solution

Definition and Configuration Management Processes).

c. Logical decomposition work products (to Technical Data Management

Processes).

C.1.3.4 Activities:

For the WBS model in

the system structure, the following activities are typically performed:

a. Define one or

more logical decomposition models based on the defined technical

requirements to gain a more detailed understanding and definition of the

design problem to be solved.

b.Allocate the

technical requirements to the logical decomposition models to form a

set of derived technical requirement statements that have the following

characteristics:

1.Describe functional and performance, service and attribute, time, and

data flow requirements, etc., as appropriate for the selected set of logical

decomposition models.

2.Individually are complete sentences and are clear, correct, and feasible

to satisfy; not stated as to how to be satisfied; implementable; only have one

interpretation of meaning, one actor-verb-object expectation; and can be

validated at the level of the system structure at which it is stated.

3.In pairs or as a set, have an absence of redundancy, are adequately

related with respect to terms used, and are not in conflict with one another.

4.Form a set of detailed "design-to" requirements.

c. Resolve derived

technical requirement conflicts.

d.Validate that

the resulting set of derived technical requirements have: (1)

bidirectional traceability with the set of validated technical requirements and

(2) assumptions and decision rationale consistent with the source set of

technical requirements.

e. Establish the

derived technical requirements baseline.

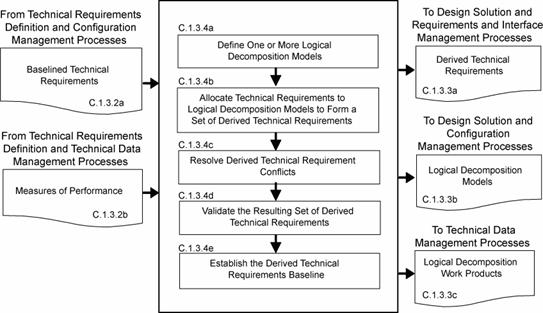

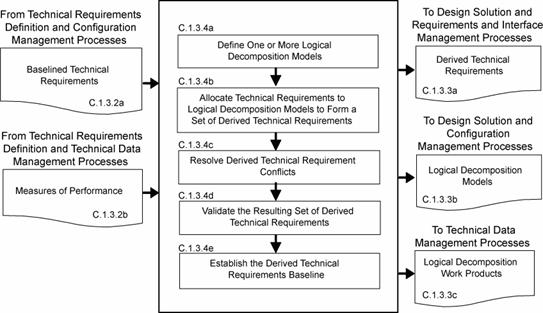

C.1.3.5 Process Flow Diagram

A typical process flow diagram for logical

decomposition is provided in Figure C-3 with inputs and their sources and the

outputs and their destinations. The activities of the logical

decomposition process are truncated to indicate the action and object of the

action.

Figure C-3 - Logical Decomposition Process

C.1.4 Design

Solution Definition Process

C.1.4.2 Inputs and Sources:

a. A baselined set of logical decomposition models (from Logical

Decomposition and Configuration Management Processes).

b.A

baseline set of derived technical requirements including interface

requirements (from Logical Decomposition and Configuration

Management Processes).

C.1.4.3 Outputs and Destinations:

The specified requirements that describe the

system design solution definition for the products of the WBS model

under development include:

a. A WBS model design solution definition set of requirements for the

system (see WBS definition in Appendix A), including specification

configuration documentation and external interface specification (to

Requirements and Interface Management Process).

b.A

baseline set of "make-to," "buy-to," "reuse-to," or set of "assemble and

integrate-to" specified requirements (specifications and configuration

documents) for the desired end product of the WBS model, including

interface specifications (to Requirements and Interface Management Process).

c. The initial

specifications for WBS model subsystems for flow down to the next

applicable lower level WBS models, including interface specifications (to

Stakeholder Expectations Definition, and Requirements and Interface

Management Processes).

d.The requirements for enabling products that will be needed to

provide life-cycle support to the end products, including interface

requirements (to

Stakeholder Expectations Definition Process for development

of enabling products or to Product Implementation Process for acquisition

of existing enabling products, and Requirements and Interface Management

Processes).

e. A product

verification plan that will be used to demonstrate that the product

generated from the design solution definition conforms to the design solution

definition specified requirements (to Product Verification Process).

f.

A product

validation plan that will be used to demonstrate that the product

generated from the design solution definition conforms to its set of

stakeholder expectations (to Product Validation Process).

g. Baseline operate-to and logistics procedures (to Technical Data

Management Process).

C.1.4.4 Activities

For the WBS model in the system structure, the following

activities are typically performed:

a. Define

alternative solutions for the system end product being developed or

improved that are consistent with derived technical requirements and

non-allocated technical requirements, if any.

b.Analyze each alternative solution against defined criteria such as:

satisfaction of external interface requirements; technology requirements;

off-the-shelf availability of products; physical failure modes, effects and

criticality; life-cycle cost and support considerations; capacity to evolve;

make vs. buy; standardization of products; integration concerns; and context of

use issues of operators considering tasks, location, workplace equipment, and

ambient conditions.

c. Select the best

solution alternative based on the analysis results of each alternative solution

and technical decision analysis recommendations.

d.Generate the

full design description of the selected alternative solution in a form

appropriate to the product-line life-cycle phase, location of the

WBS model in the system structure, and phase exit criteria to

include: (1) system specification and external interface specifications;

(2) end product specifications, configuration description documents, and

interface specifications; (3) end product subsystem initial specifications, if

subsystems are required; (4) requirements for associated supporting enabling

products; (5) end product verification plan; (6) end product

validation plan; and (7) applicable logistics and operate-to procedures.

e. Verify that

the design solution definition: (1) is realizable within

constraints imposed on the technical effort; (2) has specified

requirements that are stated in acceptable statements and have bidirectional

traceability with the derived technical requirements, technical requirements

and stakeholder expectations; (3) has decisions and assumptions made in

forming the solution consistent with its set of derived technical requirements,

separately allocated technical requirements, and identified system product

and service constraints.

f.

Baseline the

design solution definition specified requirements including the specifications

and configuration descriptions.

g. Initiate

development or acquisition of the life cycle supporting enabling

products needed, as applicable, for research, development, fabrication,

integration, test, deployment, operations, sustainment, and disposal.

h. Initiate

development of the system products of the next lower level WBS model,

if any.

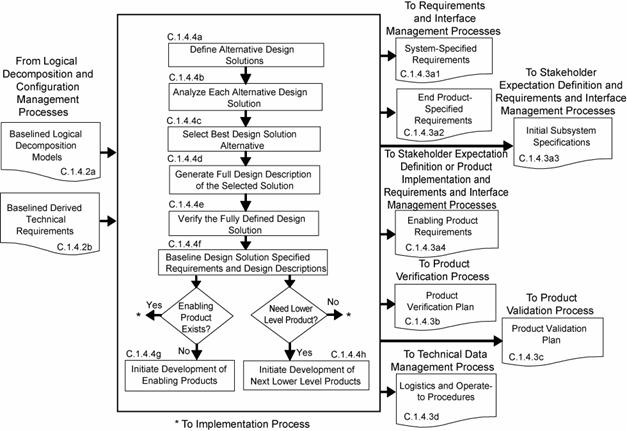

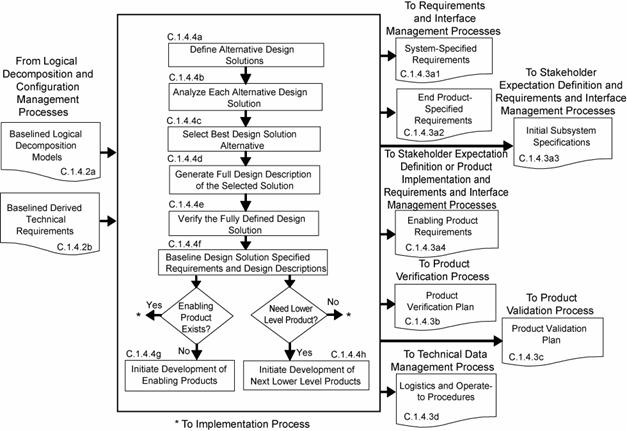

C.1.4.5 Process Flow Diagram

A typical process flow diagram for design solution

definition is provided in Figure C-4 with inputs and their sources and the

outputs and their destinations. The activities of the design solution

definition process are truncated to indicate the action and object of the

action.

Figure C-4 - Design Solution Definition Process

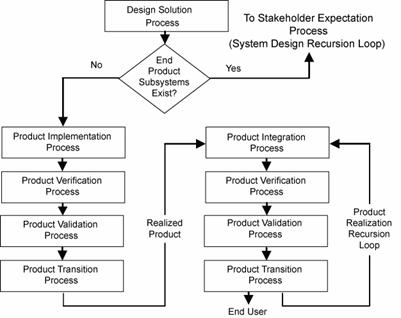

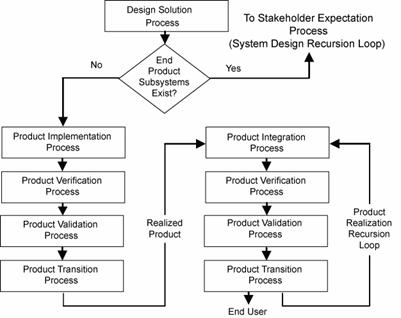

There are five product realization processes. Four of the

product realization processes are applied to each end product of a

WBS model from the bottom to the top of the system structure: (1)

either product implementation or product integration, (2) product

verification, (3) product validation, and (4) product transition. (See Figure 3-2) The form of the end product realized will be

dependent on the applicable product-line life-cycle phase, location within the

system structure of the WBS model containing the end product, and the exit

criteria of the phase. Typical early phase products are in the form of

reports, models, simulations, mockups, prototypes, or demonstrators. Later

phase product forms include the final mission products, including payloads

and experiment equipment. For software products, the technical team should

refer to NPR 7150.2 for software product realization requirements. The

technical team should also ensure that the process implementations comply

with NPR 7150.2, NASA Software Engineering Requirements for software aspects of

the system. The product realization process descriptions that follow assume

that each lowest level product goes through the sequencing shown in Figure

C-5a. Exceptions will need to be planned according to what has and has not been

already performed.

Figure C-5a -Sequencing of Design Realization Processes

C.2.1.2 Inputs and Sources:

a. Raw materials needed to make the end product (from existing resources or

external sources).

b.End product design solution definition specified requirements

(specifications) and configuration documentation for the end product of the

applicable WBS model, including interface specifications, in the form

appropriate to satisfying the product-line life-cycle phase exit

criteria (from Configuration Management Process).

c. Product implementation enabling products (from existing resources

or Product Transition Process for enabling product realization).

C.2.1.3 Outputs and Destinations:

a. Made, bought,

or reused end product in the form appropriate to the product-line life-cycle

phase and to satisfy exit criteria (to Product Verification Process).

b.Documentation

and manuals in a form appropriate for satisfying the life-cycle phase exit

criteria, including "as-built" product descriptions and "operate-to" and maintenance

manuals (to Technical Data Management Process).

c. Product implementation work products needed to provide reports, records,

and non-deliverable outcomes of process activities (to Technical Data

Management Process).

C.2.1.4 Activities

For the WBS model in the system structure, the following

activities are typically performed:

a. Prepare to conduct product implementation to include (1) preparing a

product implementation strategy and detailed planning and procedures; and (2)

determining whether the product configuration documentation is adequately

complete to conduct the type of product implementation as applicable for the

product-line life-cycle phase, location of the product in the

system structure, and phase exit criteria.

b.If the strategy is for buying an existing product, participate in the

buy of the product including (1) review of the technical information made

available by vendors; (2) assisting in the preparation of requests for

acquiring the product from a vendor; (3) assisting in the inspection of the

delivered product and the accompanying documentation; (4) determination of

whether the vendor conducted product

,validation or if it will need to be

done by a project technical team and (5) determination of the availability of

enabling products to provide test, operations, and maintenance support and

disposal services for the product.

c. If the strategy is to reuse a product that exists in the Government inventory,

participate in the acquiring of the reuse product including: (1) review of

the technical information made available for the specified product to be

reused; (2) determination of supporting documentation and user manuals

availability; (3) determination of avilability of enabling

products to provide test, operations, and maintenance support and

disposal services for the product; (5) assisting in the requests for

acquiring the product from Government sources; and (4) assisting in the

inspection of the delivered product and the accompanying documentation.

d.If the strategy is to make the product,

1.Evaluate the readiness of the product implementation enabling

products to conduct the making of the product.

2.Make the specified product in accordance with the specified

requirements, configuration documentation, and applicable standards.

3.Prepare appropriate product support documentation such as integration

constraints and/or special procedures for performing product

verification and product validation.

e. Capture work

products and related information generated while performing the product

implementation process activities.

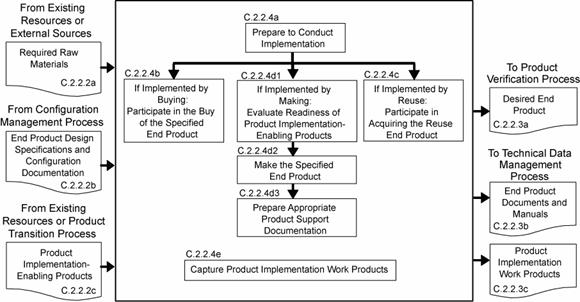

C.2.1.5 Process Flow Diagram

C.2.1.5.1 Atypical process

flow diagram for product implementation is provided in Figure C-5b with inputs

and their sources and the outputs and their destinations. The

activities of the product implementation process are truncated to indicate

the action and object of the action.

C.2.1.5.2 The path that products from

the three sources in Figure C-5b take with respect to product verification,

product validation, and product transition vary based on:

a. Whether the products bought have been verified and/or validated by the

vendor.

b.Whether reuse products that come from within the organization have

been verified and/or validated.

c. Whether the customer for the product desires to do the product

validation or have the developer perform the product validation.

Figure C-5b - Product Implementation Process

C.2.2.2 Inputs and Sources:

a. Lower-level products to be assembled and integrated (from Product

Transition Process).

b.End product design definition specified requirements (specifications)

and configuration documentation for the applicable WBS model, including

interface specifications, in the form appropriate to satisfying the

product-line life-cycle phase exit criteria (from Configuration

Management Process).

c. Product integration enabling products (from existing resources or

Product Transition Process for enabling product realization).

C.2.2.3 Outputs and Destinations:

a. Integrated product(s)

in the form appropriate to the product-line life-cycle phase and to

satisfy phase exit criteria (to Product Verification Process).

b.Documentation

and manuals in a form appropriate for satisfying the life-cycle phase exit

criteria, including "as-integrated" product descriptions and "operate-to" and

maintenance manuals (to Technical Data Management Process).

c. Product integration work products needed to provide reports, records,

and non-deliverable outcomes of process activities (to Technical Data

Management Process).

C.2.2.4 Activities

For the WBS model in the system structure, the following

activities are typically performed

a. Prepare to conduct product integration to include (1) preparing a

product integration strategy, detailed planning for the integration, and

integration sequences and procedures; and (2) determining whether the product

configuration documentation is adequately complete to conduct the type of

product integration applicable for the product-line life-cycle phase, location

of the product in the system structure, and management phase exit

criteria.

b. Obtain lower level products required to assemble and integrate into the

desired product.

c. Confirm that

the received products that are to be assembled and integrated have been

validated to demonstrate that the individual products satisfy the agreed to set

of stakeholder expectations, including interfaces requirements.

d.Prepare the

integration environment in which assembly and integration will take place

to include evaluating the readiness of the product integration enabling

products and the assigned workforce.

e. Assemble and

integrate the received products into the desired end product in accordance with

the specified requirements, configuration documentation, interface

requirements, applicable standards, and integration sequencing and procedures.

f. Prepare appropriate product support documentation such as special

procedures for performing product verification and product validation.

g. Capture work

products and related information generated while performing the product

integration process activities.

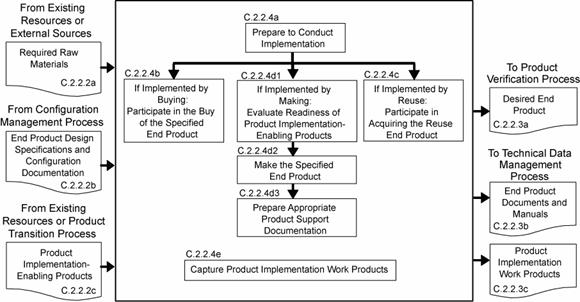

C.2.2.5 Process Flow Diagram

A typical process flow diagram for product integration

is provided in Figure C-6 with inputs and their sources and the outputs and

their destinations. The activities of the product integration process are

truncated to indicate the action and object of the action.

Figure C-6 - Product Integration Process

C.2.3.2 Inputs and Sources:

a. End product to be verified (from Product

Implementation Process or Product Integration Process).

b. End product specification

and configuration baselines, including interface specifications, to which the

product being verified was generated (from Technical Data Management Process).

c. Product verification plan (from Design Solution Definition

Process and Technical Planning Process)

d.Product verification enabling products (from existing

resources or Product Transition Process for enabling product realization).

C.2.3.3 Outputs and Destinations:

a. A verified end product (to Product Validation Process).

b. Product verification results (to Technical Assessment Process).

c. Completed

verification report to include for each specified requirement: (1) the

source paragraph references from the baseline documents for derived

technical requirements, technical requirements and

stakeholder expectations; (2) bidirectional traceability among these

sources; (3) verification type(s) to be used in performing verification of the

specified requirement; (4) reference to any special equipment, conditions, or

procedures for performing the verification; (5) results of verification

conducted; (6) variations, anomalies, or out-of-compliance results; (7)

corrective actions taken; and (8) results of corrective actions (to Technical

Data Management Process).

d. Product verification work products needed to provide reports,

records, and non-deliverable outcomes of process activities (to

Technical Data Management Process).

C.2.3.4 Activities

For the WBS model in the system structure, the following

activities are typically performed:

a. Prepare to conduct product verification to include as applicable to

the product-line life-cycle phase and WBS model location in the

system structure: (1) reviewing the product verification plan for

specific procedures, constraints, conditions under which verification will take

place, pre and post verification actions, and criteria for determining the

success or failure of verification methods and procedures; (2) arranging the

needed product verification enabling products and support resources; (3)

obtaining the end product to be verified; (4) obtaining the specification and

configuration baseline against which the verification is to be made; and

(5) establishing and checking the verification environment to ensure readiness

for performing the verification.

b.Perform the

product verification in accordance with the product verification

plan and defined procedures to collect data on each specified requirement

with specific attention given to MOPs.

c. Analyze the

outcomes of the product verification to include identification of

verification anomalies, establishing recommended corrective actions, and/or

establishing conformance to each specified requirement under controlled

conditions.

d.Prepare a

product verification report providing the evidence of product conformance

with the applicable design solution definition specified requirements

baseline to which the product was generated including bidirectional

requirements traceability and corrective actions taken to correct anomalies of

verification results.

e. Capture the

work products from the product verification.

C.2.3.5 Process Flow Diagram

A typical process flow diagram for product

verification is provided in Figure C-7 with inputs and their sources and the

outputs and their destinations. The activities of the product verification

process are truncated to indicate the action and object of the action.

Figure C-7 - Product Verification Process

C.2.4 Product

Validation Process

C.2.4.2 Inputs and Sources:

a. End product to be validated (from Product Verification Process).

b.Stakeholder requirements

baseline (from Configuration Management Process).

c. Product validation plan (from Design Solution Definition

Process and Technical Planning Process)

d.Product validation enabling products (from existing resources

or Product Transition Process for enabling product realization).

C.2.4.3 Outputs and Destinations:

a. A validated end product (to Transition Process).

b.Product validation results (to Technical Assessment Process).

c. Completed

validation report to include for each stakeholder expectation or

subset of stakeholder expectations involved with the validation, for example:

(1) the source requirement paragraph reference from the stakeholder

expectations baseline; (2) validation type(s) to be used in establishing

compliance with selected set of stakeholder expectations and match with each

source expectation referenced; (3) identification of any special equipment,

conditions or procedures for performing the validation that includes referenced

expectation; (4) results of validation conducted with respect to the referenced

expectation; (5) deficiency findings (variations, anomalies or

out-of-compliance results); (6) corrective actions taken; and (7) results of

corrective actions (to Technical Data Management Process).

d.Product validation work products needed to provide reports,

records, and non-deliverable outcomes of process activities (to

Technical Data Management Process).

C.2.4.4 Activities

For the WBS model in the system structure, the following

activities are typically performed:

a. Prepare to

conduct product validation to include as applicable to the product-line

life-cycle phase and product location in the system structure: (1)

reviewing the product validation plan for specific procedures,

constraints, conditions under which validation will take place, pre and post

validation actions, and criteria for determining the success or failure of

validation methods and procedures; (2) arranging the needed product validation

enabling products and support resources; (3) obtaining the end product to

be validated; (4) obtaining the

stakeholder expectations baseline against which the validation

is to be made; and (5) establishing and checking out the validation

environment to ensure readiness for performing the validation.

b.Perform the

product validation in accordance with the product validation plan and

defined procedures to collect data on performance of the product against

stakeholder expectations with specific attention given to MOEs.

c. Analyze the

outcomes of the product validation to include identification of validation

anomalies, establishing recommended corrective actions, and/or establishing

conformance to stakeholder expectations under operational conditions

(actual, analyzed or simulated).

d.A product

validation report providing the evidence of product conformance with the

stakeholder expectations baseline including corrective actions

taken to correct anomalies of validation results

e. Capture the

work products from the product validation.

C.2.4.5 Process Flow Diagram

A typical process flow diagram for product

validation is provided in Figure C-8 with inputs and their sources and the

outputs and their destinations. The activities of the product validation

process are truncated to indicate the action and object of the action.

Figure C-8 - Product Validation Process

C.2.5 Product

Transition Process

C.2.5.2 Inputs and Sources:

a. End product or products to be transitioned (from Product Validation

Process).

b.Documentation including

manuals, procedures and processes that are to accompany the end product

(from Technical Data Management Process).

c. Product transition enabling products to include packaging

materials, containers, handling equipment, and storage, receiving and shipping

facilities (from existing resources or Product Transition Process for

enabling product realization).

C.2.5.3 Outputs and Destinations:

a. Delivered end

product with applicable documentation including manuals, procedures and

processes in a form consistent with the product-line life-cycle

phase and location of the product in the system structure (to end

user or Product Integration Process - recursive loop).

b.Product transition work products needed to provide reports,

records, and non-deliverable outcomes of process activities (to

Technical Data Management Process).

c. Realized enabling products from existing enabling products and

services or from applying the common technical processes to develop and

realize (to Product Implementation, Integration, Verification,

Validation and Transition Processes, as appropriate)

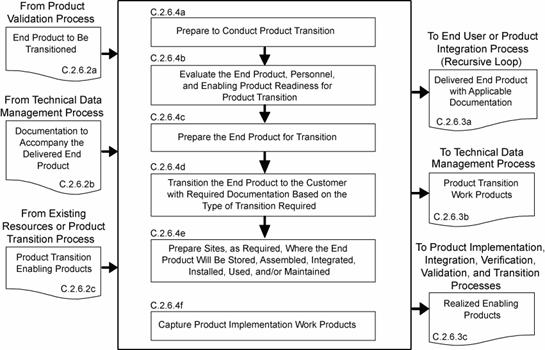

C.2.5.4 Activities

For the WBS model in the system structure, the following

activities are typically performed:

a. Prepare to

conduct product transition to include (1) preparing a product

implementation strategy to establish the type of product transition to be made

(to the next higher level customer for product integration or to an end

user); and (2) reviewing related end product stakeholder expectations and

design solution definition specified requirements to identify special

transition procedures and enabling product needs for the type of product

transition, if any, for packaging, storage, handling, shipping/transporting,

site preparation, installation, and/or sustainment.

b.Evaluate the

end product, personnel, and enabling product readiness for product

transition including: (1) availability and appropriateness of the

documentation that will be packaged and shipped with the end product; (2)

adequacy of procedures for conducting product transition; (3) availability and

skills of personnel to conduct product transition; and (4) availability of

packaging materials/containers, handling equipment, storage facilities, and

shipping/transporter services.

c. Prepare the end product for transition to include the packaging and

moving the product to the shipping/transporting location and any intermediate

storage.

d.Transition the end product with required documentation to the

customer based on the type of transition required, e.g., to the next

higher level WBS model for product integration or to the end user.

e. Prepare sites,

as required, where the end product will be stored, assembled, integrated,

installed, used, and/or maintained, as appropriate for the life-cycle phase,

position of the end product in the system structure, and

customer agreement.

f.Capture work

products from product transition process activities.

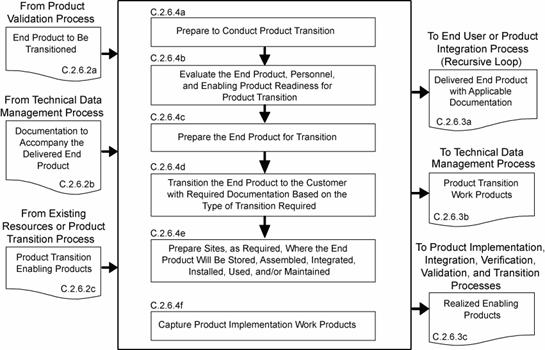

C.2.5.5 Process Flow Diagram

A typical process flow diagram for product

transition is provided in Figure C-9 with inputs and their sources and the

outputs and their destinations. The activities of the product transition

process are truncated to indicate the action and object of the action.

Figure C-9 - Product Transition Process

There are eight technical management processes-Planning,

Requirements Management, Interface Management, Risk Management, Configuration

Management, Technical Data Management, Assessment, and Decision Analysis. (See Figure 3-2.)These technical management processes are

intended to supplement the management requirements defined in NPR 7120.5.

NPR 7120.5 provides program and project managers with the technical

activities that they are required to be cognizant of and are responsible for.

On the other hand, the technical management process in this SE NPR: (1) provide

the technical team their requirements for planning, monitoring and

controlling the technical effort as well as the technical decision analysis

requirements for performing tradeoff and effectiveness analyses to support

decisionmaking throughout the technical effort; (2) focus on (a)

completion of technical process planning (preparation of the SEMP and

other technical plans), (b) technical progress assessment (using technical

measures and conducting technical reviews to assess progress against the

SEMP and defined technical requirements), and (c) control of product

requirements, product interfaces, technical risks, configurations, technical

data and include ensuring that common technical

process implementations comply with NPR 7150.2 software product

realization requirements for software aspects of the system. Documentation

produced through each technical management process should be managed and

dispositioned as Federal records.

C.3.1

Technical Planning Process

C.3.1.2 Inputs and Sources:

a. Project technical effort requirements and project resource

constraints (from the project).

b.Agreements, capability needs and applicable product-line life-cycle

phase(s) (from the project).

c. Applicable policies, procedures, standards, and organizational

processes (from the project).

d.Prior product-line life-cycle phase or baseline plans (from

Technical Data Management Process).

e. Re-planning needs (from Technical Assessment and Technical Risk

Management Processes).

C.3.1.3 Outputs and Destinations:

a. Technical work cost estimates, schedules, and resource needs, e.g.,

funds, workforce, facilities, and equipment (to project).

b.Product and process measures needed to assess progress of the

technical effort and the effectiveness of processes (to Technical Assessment

Process).

c. The SEMP and other technical plans that support implementation

of the technical effort (to all processes; applicable plans to Technical

Processes).

d.Technical work directives, e.g., work packages or task orders with work

authorization (to applicable technical teams).

e. Technical planning work products needed to provide reports, records, and

nondeliverable outcomes of process activities (to Technical Data

Management Process).

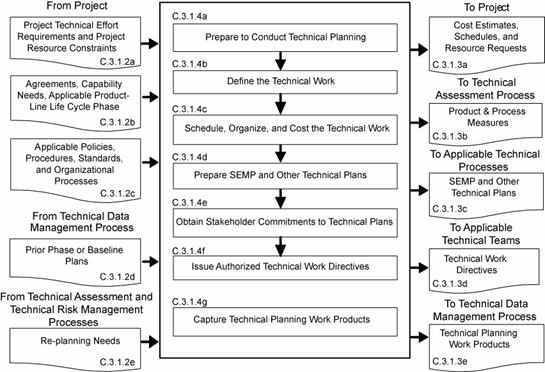

C.3.1.4 Activities

For the WBS model in the system structure, the following

activities are typically performed:

a. Prepare to conduct technical planning to include:

1.Preparing or updating a planning strategy for each of the common

technical processes of this SE NPR.

2.Determining:

a) deliverable work

products from technical efforts.

b) technical

reporting requirements.

c) other technical

information needs for reviews or satisfying product-line life-cycle

management phase entry or exit criteria.

d) product and

process measures to be used in measuring technical performance, cost, and

schedule progress.

e) key or critical

technical events with entry and success criteria.

f) data

management approach for data collection and storage and how measurement data

will be analyzed, reported, and dispositioned as Federal records.

g) technical risks

that need to be addressed in the planning effort.

h) tools and

engineering methods to be employed in the technical effort.

i) approach to

acquiring and maintaining the technical expertise needed (training and skills

development plan).

b.Define the

technical work to be done to include associated technical, support, and

management tasks needed to generate the deliverable products and satisfy entry

and success criteria of key technical events and the applicable

product-line life-cycle management phase.

c. Schedule,

organize, and cost the technical effort.

d.Prepare the

SEMP and other technical plans needed to support the technical effort

and perform the technical processes.

e. Obtain

stakeholder commitments to the technical plans.

f. Issue authorized

technical work directives to implement the technical work.

g. Capture work

products from technical planning activities

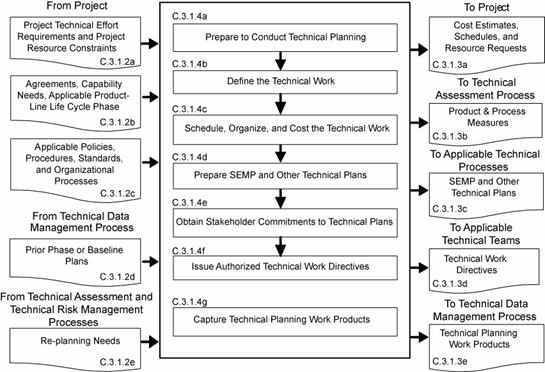

C.3.1.5 Process Flow Diagram

A typical process flow diagram for technical

planning is provided in Figure C-10 with inputs and their sources and the

outputs and their destin,ations. The activities of the technical planning process are truncated to indicate the action and object of the

action.

Figure C-10 - Technical Planning Process

C.3.2 Requirements

Management Process

C.3.2.2 Inputs and Sources:

a. Expectations and requirements to be managed (from System Design Processes).

b. Requirement change requests (the project and Technical Assessment

Process).

c. TPM estimation/evaluation results (from Technical Assessment

Process)

d.Product verification and product validation results (from

Product Verification and Validation Processes)

C.3.2.3 Outputs and Destinations:

a. Requirement documents (to Configuration Management Process).

b.Approved changes to requirement baselines (to Configuration

Management Process).

c. Requirements

management work products needed to provide reports, records and non-deliverable

outcomes of process activities (to Technical Data Management Process).

C.3.2.4 Activities

For the WBS model in the system structure, the following

activities are typically performed:

a. Prepare to conduct requirements management to include:

1. Preparing or updating a strategy and procedures for:

a) establishing that

expectation and requirement statements, singularly and as a whole, are prepared

in accordance with established formats and rules.

b) identifying

expectations and requirements to be managed, expectation and requirement

sources, allocation and traceability of requirements, and linking product

expectations and requirements with costs, weight, and power allocations as

applicable

c) formal

initiation, assessment, review, approval and disposition of

engineering change proposals and changes to expectation and requirements

baseline.

2.Selecting or updating an appropriate requirements management tool.

3.Training technical team members in the established

requirements management procedures and in the use of the selected/updated

requirements management tool.

b.Conduct requirements management to include: (1) capturing, storing

and documenting the expectations and requirements; (2) establishing that

expectation and requirement statements are compliant with format and other

established rules; (3) confirming that each established requirements

baseline has been validated; and (4) identifying and analyzing

out-of-tolerance system-critical technical parameters and unacceptable

validation and verification results and proposing requirement

appropriate changes to correct out-of-tolerance requirements.

c. Conduct expectation and requirements traceability to include: (1)

tracking expectations and requirements between baselines, especially MOEs,

MOPs, and TPMs, and (2) establishing and maintaining appropriate

requirements compliance matrixes that contain the requirements, bidirectional

traceability, compliance status, and any actions to complete compliance.

d.Manage expectation and requirement changes to include: (1) reviewing

engineering change proposals (ECPs) to determine any changes to

established requirement baselines, (2) implementing formal change procedures

for proposed and identified expectation or requirement changes, and (3)

disseminating the approved change information.

e. Capture work products from requirements management process activities to

include maintaining and reporting information on the rationale for and

disposition and implementation of change actions, current requirement

compliance status, and expectation and requirement baselines.

C.3.2.5 Process Flow Diagram

A typical process flow diagram for requirements

management is provided in Figure C-11 with inputs and their sources and the

outputs and their destinations. The activities of the requirements

management process are truncated to indicate the action and object of the

action.

Figure C-11 - Requirements Management Process

C.3.3 Interface

Management Process

C.3.3.2 Inputs and Sources:

a. Internal and external functional and physical interface

requirements for the products of a WBS model (from user or program

and System Design Processes).

b.Interface change requests (from project, and Technical Assessment

Processes).

C.3.3.3 Outputs and Destinations:

a. Interface Control Documents (to Configuration

Management Processes).

b.Approved interface requirement changes (to Configuration

Management Process)

c. Interface management work products needed to provide reports, records,

and non-deliverable outcomes of process activities (to Technical Data

Management Process)

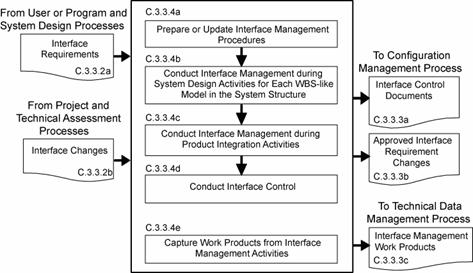

C.3.3.4 Activities

For the WBS model in the system structure, the following activities

are typically performed:

a. Prepare or

update interface management procedures for (1) establishing interface

management responsibilities for those interfaces that are part of agreement

boundaries, (2) maintaining and controlling identified internal and external

physical and functional interfaces, (3) preparing and maintaining appropriate

physical and functional interface specifications or interface control

documents and drawings to describe and control interfaces external to

the system end product, (4) identifying interfaces between system products

(including humans) and among configuration management items, (5)

establishing and implementing formal change procedures for interface evolution,

(6) disseminating the needed interface information for integration into

technical effort activities and for external interface control, and

(7) training technical teams and other applicable support and

management personnel in the established interface management procedures.

b.Conduct interface management during system design

activities for each WBS model in the system structure to include: (1)

integrating the interface management activities with requirements

management activities; (2) analyzing the concept of operations to identify

critical interfaces not included in the stakeholder set of expectations;

(3) documenting interfaces both external and internal to each WBS model as the

development of the system structure emerges and interfaces are added and

existing interfaces are changed; (4) documenting origin, destination, stimulus,

and special characteristics of interfaces; (5) maintaining the design solution

definition for internal horizontal and vertical interfaces between WBS models

in the system structure; (6) maintaining horizontal traceability of interface

requirements across interfaces and capturing status in the established

requirements compliance matrix; and (7) confirming that each interface control

document or drawing that is established has been validated with parties on

both sides of the interface.

c. Conduct interface management during product integration

activities to include: (1) reviewing product integration procedures to

ensure that interfaces are marked to ensure easy and correct

assembly/connection with other products, (2) identifying product integration

planning to identify interface discrepancies, if any, and report to the proper

technical team or technical manager, (3) confirming that a pre-check is

completed on all physical interfaces before connecting products together, (4)

evaluating assembled products for interface compatibility, (5) confirming that

product verification and product validation plans/procedures include

confirming internal and external interfaces, and (6) preparing an interface

evaluation report upon completion of integration and product verification and

product validation.

d.Conduct

interface control to include: (1) managing interface changes within the

system structure, (2) identifying and tracking proposed and directed

changes to interface specifications and interface control documents and

drawings, (3) confirming that the vertical and horizontal interface issues are

analyzed and resolved when a change affects products on both sides of the

interface, (4) controlling traceability of interface changes including source

of the change, processing methods and approvals, and (5) disseminating the

approved interface change information for integration into technical efforts at

every level of the project.

e. Capture work

products from interface management activities.

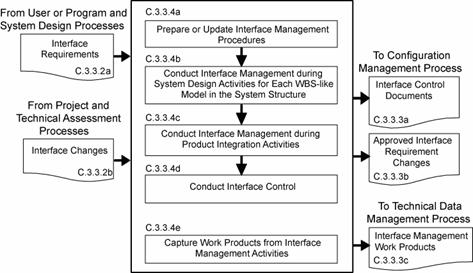

C.3.3.5 Process Flow Diagram

A typical process flow diagram for interface

management is provided in Figure C-12 with inputs and their sources and the

outputs and their destinations. The activities of the interface management

process are truncated to indicate the action and object of the action.

Figure C-12 - Interface Management Process

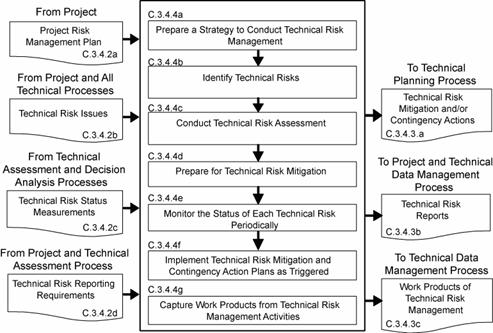

C.3.4Technical Risk Management Process

C.3.4.2 Inputs and Sources:

a. Project Risk Management Plan (from project)

b.Technical risk issues (from project and other common technical

processes).

c. Technical risk status measurements (from Technical Assessment and

Decision Analysis Processes).

d.Technical risk reporting requirements (from project and Technical

Planning Process).

C.3.4.3 Outputs and Destinations:

a. Technical risk mitigation and/or contingency actions (to Technical

Planning Process for re-planning and/or re-direction).

b.Technical risk reports (to project and Technical Data Management

Process).

c. Work products from technical risk management activities (to

Technical Data Management Process).

C.3.4.4 Activities

For the WBS model in the system structure, the following

activities are typically performed; (NPR 8000.4, Risk Management Procedural

Requirements, is to be used as a source document for defining this process and

implementing procedures.)

a. Prepare a strategy to conduct technical risk management to include:

(1) documenting how the project risk management plan will be implemented

in the technical effort; (2) planning identification of technical risk sources

and categories; (3) identification of potential technical risks; (4)

characterizing and prioritizing technical risks; (5) planning informed

technical management (mitigation) actions should the risk event occur; (6)

tracking technical risk status against established trigger; (7) resolving

technical risk by taking planned action if established trigger is tripped; and

(8) communicating technical risk status and mitigation actions taken, when

appropriate.

b.Identify

technical risks to include: (1) identifying sources of risk issues related to

the technical effort; (2) anticipate what can go wrong in each of the source

areas to create technical risk issues; (3) analyzing identified technical risks

for cause and importance; (4) preparing clear, understandable, and standard

form risk statements; and (5) coordinating with relevant

stakeholders associated with each identified technical risk.

c. Conduct

technical risk assessment to include: (1) categorizing the severity of

consequences for each identified technical risk in terms of performance, cost,

and schedule impacts to the technical effort and project; (2) analyze the

likelihood and uncertainties of events associated with each technical risk and

quantify (for example by probabilities) or qualify (for example by high,

moderate, or low) the probability of occurrence in accordance with project risk

management plan rules; and (3) prioritize risks for mitigation.

d.Prepare for technical risk mitigation to include: (1) selecting risks for

risk mitigation and monitoring, (2) selecting an appropriate risk handling

approach, (3) establishing the risk level or threshold when risk occurrence

becomes unacceptable and triggers execution of a risk mitigation action plan,

(4) selecting contingency actions and triggers should risk mitigation not work

to prevent a problem occurrence, (5) preparing risk mitigation and contingency

action plans with identification of responsibilities and authorities.

e. Monitor the status of each technical risk periodically to include: (1)

tracking risk status to determine whether conditions or situations have changed

so that a risk monitoring is no longer needed or new risks have been

discovered, (2) comparing risk status and risk thresholds, (3) reporting risk status

to decision authorities when a threshold has been triggered and an action

plan implemented, (4) preparing technical risk status reports as required by

the project risk management plan, (5) communicating risk status during

technical reviews in the form specified by the project risk management

plan.

f.

Implement technical risk mitigation and contingency action plans when

the applicable thresholds have been triggered to include: (1) monitoring the

results of the action plan implemented, (2) modifying the action plan as

appropriate to the results of the actions, (3) continuing actions until the

residual risk and/or consequences impacts are acceptable or become a problem to

be solved, (4) communicate to the project when risks are beyond the scope of

the technical effort to control, will affect a product higher in the

system structure, or represent a significant threat to the technical

effort or project success, (5) preparing action plan effectiveness reports as

required by the project risk management plan, (6) communicating action

plan effectiveness during technical reviews in the form specified by the

project risk management plan.

g. Capture work

products from technical risk management activities.

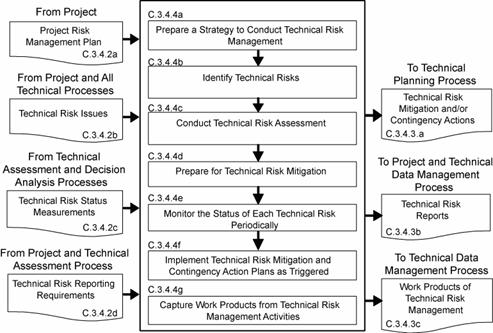

C.3.4.5 Process Flow Diagram

A typical process flow diagram for technical risk

management is provided in Figure C-13 with inputs and their sources and the

outputs and their destinations. The activities of the technical risk

management process are truncated to indicate the action and object of the action.

Figure C-13 - Technical Risk Management Process

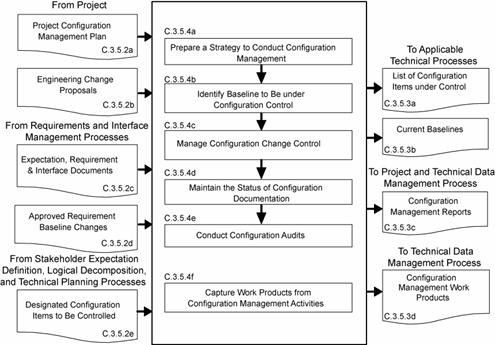

C.3.5Configuration Management Process

C.3.5.2 Inputs and Sources:

a. Project configuration management plan, if any (from project).

b. ECPs (from contractors, if any, and technical teams).

c. Expectations and requirement outputs to include

stakeholder expectations, technical requirements, derived technical

requirements, system and end product specifications, requirement

documents, and interface control documents/drawings (from Requirements and

Interface Management Processes).

d.Approved requirement baseline changes, including interface

requirement changes (from Requirements Management and Interface

Management Processes).

e. Concepts of operations, enabling product strategies, logical

decomposition models, SEMP, technical plans, and other configuration items

identified in the list of CIs to be controlled (from

Stakeholder Expectation Definition, Logical Decomposition, Technical

Planning, and other technical processes as appropriate).

C.3.5.3 Outputs and Destinations:

a. List of configuration items to be placed under control (to

applicable technical processes).

b.Current

baselines (to Technical Requirements Definition, Logical

Decomposition, Design Solution Definition, and Product Implementation,

Integration, Verification, and Validation Processes.)

c. Configuration management reports (to project and Technical Data

Management Process).

d.Work products from configuration management activities (to

Technical Data Management Process).

C.3.5.4 Activities

For the WBS model in the system structure, the following

activities are typically performed:

a. Prepare a strategy to conduct configuration management for the

system products and designated work products to include: (1) documenting

how the project configuration management plan, if any, will be implemented; (2)

identifying configuration items to be put under configuration control; (3)

identifying schema of identifiers to accurately describe a configuration item

and its revisions or versions; (4) controlling changes to configuration items;

(5) maintaining and reporting disposition and implementation of change actions

to appropriate stakeholders including technical teams within the

project; (6) ensuring that products are in compliance with specifications and

configuration documentation during reviews and audits; (7) providing the

appropriate reference configuration at the start of each product-line

life-cycle phase; (8) obtaining appropriate tools for configuration management;

and (9) training appropriate technical team members and other technical

support and management personnel in the established configuration management

strategy and any configuration management procedures and tools.

b. Identify

baselines to be under configuration control to include: (1) listing

of the configuration items to control; (2) providing each configuration item

with a unique identifier; (3) identifying acceptance requirements for each

baseline identified for control; (4) identifying the owner of each

configuration item; and (5) establishing a baseline configuration for each

configuration item.

c. Manage

configuration change control to include: (1) establishing change criteria,

procedures, and responsibilities; (2) receive, record, and evaluate change

requests; (3) tracking change requests to closure; (4) obtaining appropriate

approvals before implementing a change; (5) incorporating approved changes in

appropriate configuration items; (6) releasing changed configuration items for

use; and (7) monitoring implementation to determine whether changes resulted in

unintended effects (e.g., have not compromised safety or security of

baseline product).

d.Maintain the status of configuration documentation to include: (1)

maintaining configuration item description records and records that

verify readiness of configuration items for testing, delivery, or other

related technical efforts; (2) maintaining change requests, disposition action

taken, and history of change status; (3) maintaining differences between

successive baselines; and (4) controlling access to and release of

configuration baselines.

e. Conduct configuration audits to include: (1) auditing

baselines under control to confirm that the actual work product

configuration matches the documented configuration, the configuration is in

conformance with product requirements, and records of all change actions are

complete and up to date; (2) identifying risks to the technical effort based on

incorrect documentation, implementation, or tracking of changes; (3) assessing

the integrity of the baselines; (4) confirming the completeness and correctness

of the content of configuration items with applicable requirements; (5)

confirming compliance of configuration items with applicable configuration

management standards and procedures; and (6) tracking action items to

correct anomalies from audit to closure.

f.

Capture work products from configuration

management activities to include a list of identified configuration

items; description of configuration items placed under control; change requests

and disposition of the request and rationale for the disposition; documented

changes with reason for change and change action; archive of old baselines; and

required reports on configuration management outcomes.

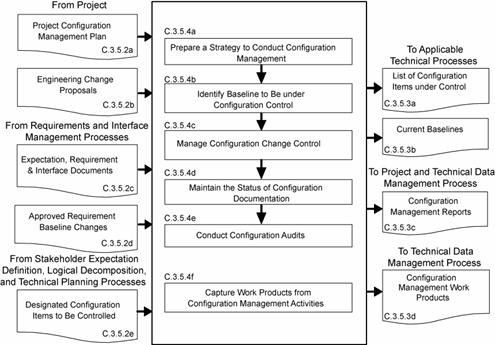

C.3.5.5 Process Flow Diagram

A typical process flow diagram for configuration

management is provided in Figure C-14 with inputs and their sources and the

outputs and their destinations. The activities of the configuration

management process are truncated to indicate the action and object of the

action.

Figure C-14 - Configuration Management Process

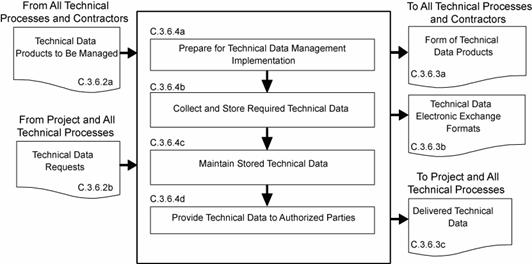

C.3.6 Technical

Data Management Process

C.3.6.2 Inputs and Sources:

a. Technical data and work products to be managed (from all technical

processes and contractors).

b.Requests for technical data (from all technical processes and

project).

C.3.6.3 Outputs and Destinations:

a. Form of technical data products (to all technical processes and

contractors).

b.Technical data electronic exchange formats (to all technical

processes and contractors).

c. Delivered technical data (to project and all technical processes).

C.3.6.4 Activities

For the WBS model in the system structure, the following

activities are typically performed:

a. Prepare a strategy for the conduct of technical data management to

include: (1) determining required data content and form and electronic data

exchange interfaces in accordance with international standards or agreements;

(2) establishing a framework for technical data flow within the project

technical processes and to/from contractors; (3) designating technical

data management responsibilities and authorities regarding origination,

generation, capture, archiving, security, privacy and disposal of

technical data work products; (4) establishing the rights, obligations, and

commitments regarding the retention of, transmission of, and access to

technical data items; (5) establishing relevant data storage, transformation,

transmission, and presentation standards and conventions to be used, project or

program policy, and agreements or legislative constraints; (6) describing the

methods, tools, and metrics used during the technical effort and for

technical data management; and (7) training appropriate technical

team members and support and management personnel in the established

technical data management strategy and related procedures and tools.

b.Collect and store required technical data to include: (1) identifying

existing sources of technical data that are designated as outputs of the common

technical processes; (2) collecting and storing technical data in accordance

with the technical data management strategy and procedures; (3) recording and

distributing lessons learned; (4) performing technical data integrity checks on

collected data to confirm compliance with content and format requirements and

identifying errors in specifying or recording data; and (5) prioritizing,

reviewing, and updating technical data collection and storage procedures.

c. Maintain stored technical data to include: (1) managing the databases to

maintain proper quality and integrity of the collected and stored technical

data and to confirm that the technical data is secure and is available to those

with authority to have access; (2) performing technical data maintenance

as required; (3) preventing the stored data from being used or accessed

inappropriately; (4) maintaining the stored technical data in a manner that

protects it against foreseeable hazards such as fire, flood, earthquake, and

riots; and (5) maintaining periodic back-ups of each technical database.

d.Provide technical data to authorized parties to include: (1) maintaining

an information library or reference index to provide data available and access

instructions; (2) receiving and evaluating requests for technical data and

delivery instructions; (3) confirming that required and requested technical

data is appropriately distributed to satisfy the needs of the requesting party

and in accordance with established procedures, directives, and agreements; (4)

confirming that electronic access rules are followed before allowing access to

the database and before any data is electronically released/transferred to the

requester; and (5) provide proof of correctness, reliability, and security of

technical data provided to internal and external recipients.

C.3.6.5 Process Flow Diagram

A typical process flow diagram for technical data

management is provided in Figure C-15 with inputs and their sources and the

outputs and their destinations. The activities of the technical data

management process are truncated to indicate the action and object of the

action.

Figure C-15 - Technical Data Management Process

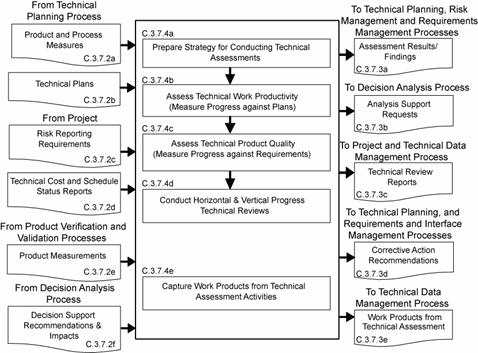

C.3.7 Technical

Assessment Process

C.3.7.2 Inputs and Sources:

a. Process and product measures (from Technical Planning Process).

b.Technical plans including the SEMP (from Technical Planning

Process).

c. Risk reporting requirements during technical reviews (from

project).

d.Technical cost and schedule status reports (from project).

e. Product measurements (from Product Verification and Product Validation

Processes).

f.

Decision support recommendations and impacts (from Decision

Analysis Process).

C.3.7.3 Outputs and Destinations:

,

a. Assessment results and findings including technical performance measurement estimates of measures (to Technical Planning, Technical Risk

Management and Requirements Management Processes).

b.Analysis support requests (to Decision Analysis Process).

c. Technical review reports (to project and Technical Data Management

Process).

d.Corrective action and requirement change recommendations including

corrective actions to correct out-of-tolerance TPMs (to Technical

Planning, Requirements Management, and Interface Management Processes).

e. Work products from technical assessment activities (to Technical

Data Management Process).

C.3.7.4 Activities

For the WBS model in the system structure, the following

activities are typically performed:

a. Prepare a strategy for conducting technical assessments to include:

(1) identifying the plans against which progress and achievements of the

technical effort are to be assessed; (2) establishing procedures for obtaining

cost expenditures against work planned and task completions against schedule;

(3) identifying and obtaining technical requirements against which product

development progress and achievement will be assessed and establishing the

procedures for conducting the assessments; (4) establishing events when TPMs,

estimation or measurement techniques, and rules for taking action when

out-of-tolerance conditions exist will be assessed; (5) identifying and

planning for phase-to-phase technical reviews and WBS model-to-model

vertical progress reviews, as well as establishing review entry and

success criteria, review board members, and close out procedures; (6)

establishing which technical effort work products will undergo peer review, the

team members who will perform the peer reviews, and reporting requirements; and

(7) training team members, support staff, and managers involved in

conducting technical assessment activities.

b.Assess technical work productivity (progress and achievement against

plans) to include: (1) identifying, collecting, and analyzing

process measures (e.g., earned value measurements for measuring progress

against planned cost, schedule, resource use, and technical effort tasks) and

identifying and reporting cost-effective changes to correct variances; (2)

monitoring stakeholder involvement according to the SEMP; and (3)

monitoring technical data management against plans.

c. Assess product

quality (progress and achievements against technical requirements) to include:

(1) identifying, collecting, and analyzing the degree of technical requirement

and TPM satisfaction; (2) assessing the maturity of the WBS model products

and services as applicable to the applicable product-line life-cycle phases;

(3) determining any variances from expected values of product performance and

identifying and defining cost-effective changes to correct variances.

d.Conduct technical reviews to include:

(1) identifying the type of technical reviews and each review's purpose and

objectives (see Chapter 5 for specific technical reviews that apply); (2)

determining progress toward satisfying entry criteria; (3) establishing the

makeup of the review team; (4) preparing the review presentation materials; and

(5) identifying and resolving action items resulting from the review.

e. Capture work products from the conduct of technical

assessment activities to include: (1) identifying variances resulting

from technical assessments; (2) identifying and reporting changes to correct

variances; (3) recording methods used in doing assessment activities; (4)

documenting assumptions made in arriving at the process and product

measure outcomes; and (5) reporting corrective action recommendations.

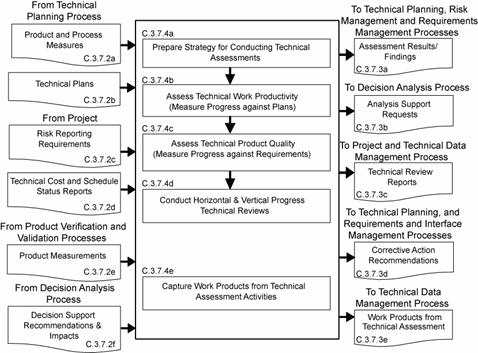

C.3.7.5 Process Flow Diagram

A typical process flow diagram for technical

assessment is provided in Figure C-16 with inputs and their sources and

the outputs and their destinations. The activities of the technical

assessment process are truncated to indicate the action and object of the

action.

Figure C-16 - Technical Assessment Process

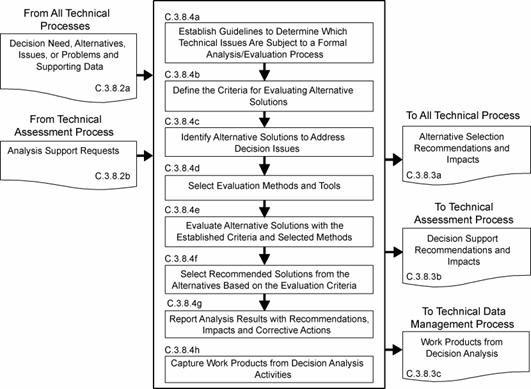

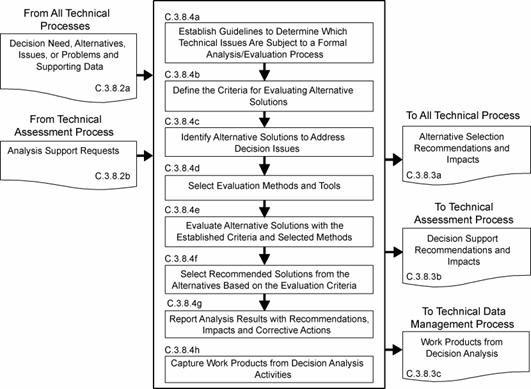

C.3.8Decision Analysis Process

C.3.8.2 Inputs and Sources:

a. Decision need, alternatives, issues, or problems and supporting data

(from all Technical Processes).

b.Analysis support requests (from Technical Assessment Process).

C.3.8.3 Outputs and Destinations:

a. Alternative selection recommendations and impacts (to all Technical

Processes)

b.Decision support recommendations and impacts (to Technical Assessment

Process)

c. Work products of decision analysis activities (to Technical

Data Management Process).

C.3.8.4 Activities

For the WBS model in the system structure, the following

activities are typically performed:

a. Establish guidelines to determine which technical issues are subject to

a formal analysis/evaluation process to include: (1) when to use a formal

decisionmaking procedure, for example, as a result of an effectiveness

assessment, a technical trade off, a problem needing to be solved, action

needed as a response to risk exceeding the acceptable threshold,

verification or validation failure, make-buy choice, evaluating a

solution alternative, or resolving a requirements conflict; (2) what needs to

be documented; (3) who will be the decision makers and their responsibilities

and decision authorities; (4) how decisions will be handled that do not require

a formal evaluation procedure.

b. Define the criteria for evaluating alternative solutions to include: (1)

the types of criteria to consider including the following: technology

limitations, environmental impact, safety, risks, total ownership and

life-cycle costs, and schedule impact; (2) the acceptable range and scale

of the criteria; and (3) the rank of each criterion by its importance.

c. Identify alternative solutions to address decision issues to include

alternatives for consideration in addition to those that may be provided with

the issue.

d.Select

evaluation methods and tools/techniques based on the purpose for analyzing a

decision and on the availability of the information used to support the method

and/or tool.

e. Evaluate alternative solutions with the established criteria and selected

methods to include: (1) evaluation of assumptions related to evaluation

criteria and of the evidence that supports the assumptions; and (2) evaluation

of whether uncertainty in the values for alternative solutions affects the

evaluation.

f. Select recommended solutions from the alternatives based on the

evaluation criteria to include documenting the information that justifies the

recommendations and gives the impacts of taking the recommended course of

action.

g. Report the analysis/evaluation results/findings with recommendations,

impacts, and corrective actions.

h.