Procedural

Requirements

Effective Date: October 07, 2015

Expiration Date: October 06, 2025

|

NASA Procedural Requirements |

NPR 8831.2F Effective Date: October 07, 2015 Expiration Date: October 06, 2025 |

| | TOC | Change History | Preface | Chapter1 | Chapter2 | Chapter3 | Chapter4 | Chapter5 | Chapter6 | Chapter7 | Chapter8 | Chapter9 | Chapter10 | Chapter11 | Chapter12 | AppendixA | AppendixB | AppendixC | AppendixD | AppendixE | AppendixF | AppendixG | AppendixH | AppendixI | ALL | |

This appendix recommends sample forms for use in facilities maintenance management. The information in the forms should be part of a Computerized Maintenance Management System (CMMS) database. The forms should be tailored to meet the needs of the users, the capabilities of the CMMS, and the other automation systems used. (The sample forms also should prove useful when comparing reports and formats during the evaluation of candidate CMMSs.)

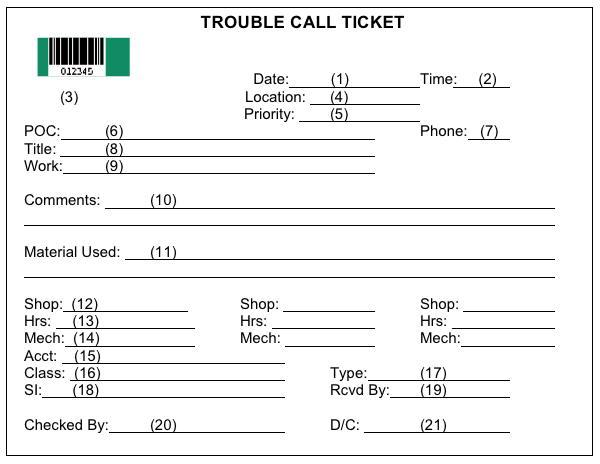

D.1 Trouble Call Ticket, Telephone or E-mail

D.1.1 Sample Trouble Call Ticket. Figure D-1 is a sample TC ticket. It is used with TCs, may be used as an alternative to a standard work order for small jobs (typically involving 20 work hours or less effort), and is used for work that usually is not planned or estimated. It contains data fields considered essential for effectively managing TC and small jobs. Usually, it is printed on half-size sheets (often card stock) or is in electronic format on palm-top computers for use by technicians in the field. A printer may be located in the shops, remote from the work reception center, to speed TC ticket delivery.

D.1.2 Data Elements. The following data elements are recommended for the TC ticket system. The elements provide the information that the crafts personnel need to perform the work and that management needs to analyze the work. All listed information need not be recorded if it is available in the CMMS or can be obtained from other data elements. For example, the FMS code does not need to be recorded if it can be obtained from the accounting data.

| Data Fields | Definition | |

| 1. | Date | The date the work was received by the work reception desk. |

| 2. | Time | The time the work was received by the work reception desk. |

| 3. | Work Order Number | The unique identifying number assigned to the TC ticket. On the example, it is shown in bar code as well as in numerals. (The use of bar codes can speed data entry and reduce data entry errors.) |

| 4. | Location | The facility number and any other pertinent data regarding the location or work site of the requested work. |

| 5. | Priority | The work priority rating. |

| 6. | POC | Point of Contact (POC), the name of the person requesting the work. |

| 7. | Phone | The telephone number of the POC. |

| 8. | Title | A short description of the work. This should contain descriptive key words that can be used later for database searches for similar work. |

| 9. | Work | A detailed statement of the work. |

| 10. | Comments | A space for the shops to record comments on the work performed. |

| 11. | Material Used | The material used for the TC ticket if beyond that carried as bench stock or in preexpended bins. |

| 12. | Shop | The craft shop performing the work. (The form permits entering up to three shops.) |

| 13. | Hours | Hours, the amount of labor used to complete the TC ticket by each shop involved. |

| 14. | Mech | Mechanic, the initials (or other identifier) of the mechanic performing the work. |

| 15. | Acct | Accounting, the accounting data or charge number for financial accounting. |

| 16. | Class | Class, a locally definable descriptor for the work that can be used for analysis of TC tickets. |

| 17. | Type | Work Element, defined in section 1.5.1.c. |

| 18. | SI | Special Interest, the indicator defined in section 5.5.4.3.d. |

| 19. | Rcvd By | Received By, the person receiving the request for work. |

| 20. | Checked By | The person checking the completed work, if any (usually the supervisor). |

| 21. | D/C | Date Completed, date work completed (could include time also). |

Figure D-1 Sample Form: Trouble Call Ticket

D.1.3 Instructions for Use. The TC ticket should be automated as part of the CMMS. Initial data entry can then be accomplished at a computer terminal by the work reception clerk as the work is received. In many cases, requests will be received by telephone. However, they may be received by electronic mail. A TC ticket may be the means of issuing facilities maintenance work requested by other means, such as a request for facilities maintenance services (see section D.2, Request for Facilities Maintenance Services), or as the result of an inspection, when the scope of work is small. The following discusses use of the form.

a. The work order number is normally assigned by the CMMS. However, this can be accomplished manually. If it is assigned manually, it should be checked for duplications. The use of a bar code can speed subsequent processing and closing the TC ticket while reducing data-entry errors. (Most CMMSs support printing of bar codes.)

b. The work reception clerk enters the Date, Time, Location, Priority, POC, Phone, Title, and Work data. Normally, this information is obtained during the initial telephone request. The clerk will use the Center's priority system when assigning the priority. The Work data entry may take the form of a description of the problem or the desired result; for example, "Door closer is broken" or "Fix leaking sink." The Work data entry also can include special coordination instructions or specific due dates. It is essential that the POC and Phone data entries be correct to permit the shops to obtain additional information, if required. Based on the foregoing information, the work reception clerk determines and enters the Scope, Type, Special Interest (SI), and accounting data (Acct). The clerk completes the form by entering the name or other identifier in the Rcvd By block. (Bar coding can expedite completion of the ticket by using a dictionary of standard terms, phrases, and other data available to the work reception clerk. The clerk can scan a bar code dictionary entry in lieu of typing a data field. This offers the dual advantages of reducing keyboard errors and using standard vocabulary for the data element.) Once this data is entered, the TC ticket is sent to the shops.

c. The shop supervisor reviews the TC ticket and assigns it to a mechanic for accomplishment, in accordance with its priority. Routine work is normally grouped by location and craft to minimize time lost in travel. In some cases a job may require specialized skills not found in the shop that normally performs TC tickets, in which case, it is assigned to another shop for completion; for example, machining a special fitting.

d. The mechanic performing the work enters the work performed in the Comments area and the Material Used if material beyond that carried as bench stock or in preexpended bins is required. Alternatively, the Materials Used information may be obtained as part of a materials management module in the CMMS when the material is issued to the mechanic. Unusual conditions encountered are noted in the Comments block as well. The mechanic initials the form upon completion.

e. The shop supervisor enters the identification and the labor hours used on the TC ticket. The shop supervisor checks the completed form to ensure that all entries are made and returns it to the work control center to be closed. If the supervisor or other official inspects the competed work, this is indicated by initialing the "Checked By" block.

f. When the completed form is returned to the work control center, it is closed by entering the completion data in the CMMS. This will normally include labor and material expenditures, completion date, and applicable comments on work performed. The information becomes part of the maintenance history file. A hard copy of the TC ticket need not be retained if the data is stored in the CMMS and backed up. If it is determined by the mechanic or supervisor that followup action is required, the work reception clerk enters the required action into the work control system. This may take the form of another TC ticket or a request for facilities maintenance services. (See section D.2, Request for Facilities Maintenance Services.)

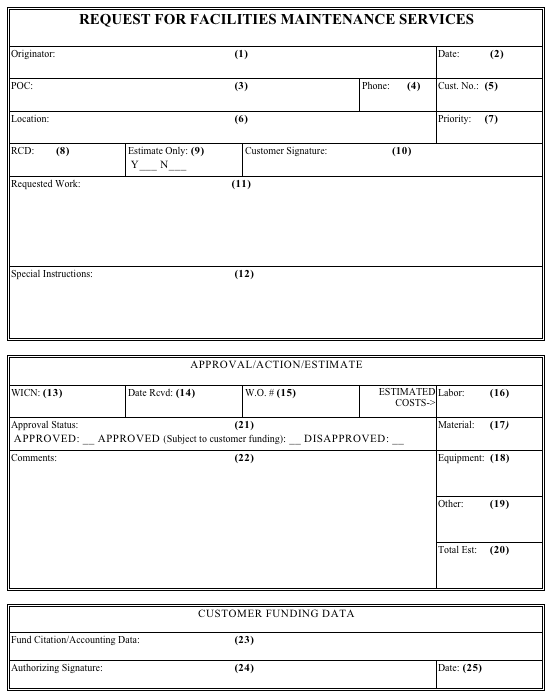

D.2 Request for Facilities Maintenance Services Electronic

D.2.1 Sample Form: Request for Facilities Maintenance Services, Figure D-2, is a sample form to be used by customers to document SRs or to request other facilities maintenance services. The primary purpose for this form is to document requests for work. The key factors are ensuring that sufficient data is obtained to identify, describe, and manage the work; that the work is properly authorized; that the work is properly tracked; and that accountability is maintained. The work may be accomplished as a TC ticket, a work order, or by separate contract, depending on its urgency, scope, and cost. The determination on how the work is accomplished is made as part of the facilities maintenance management process.

Figure D-2 Sample Form: Request for Facilities Maintenance Services

D.2.2 Data Elements

| Data Fields: | Definition: | |

| 1. | Originator: | The name (or other identifier) of the requesting organization/customer. |

| 2. | Date: | The date the request is submitted. |

| 3. | POC: | Point of Contact, the name of the person to be contacted regarding the request. |

| 4. | Phone: | The telephone number for the POC. |

| 5. | Cust. No.: | Customer Number, an identification number assigned by the submitting organization. (This is optional, but it gives the originator the ability to assign the organization's own identification or tracking number.) |

| 6. | Location: | The facility number and any other pertinent data regarding the location where the work is to be done. |

| 7. | Priority: | The work priority rating. |

| 8. | RCD: | Requested Completion Date, the completion date requested for the services. |

| 9. | Estimate: | An indicator that the originator wants a cost estimate only for the work requested rather than immediate performance of the work. |

| 10. | Customer Signature: | The signature of an individual authorized to submit requests from the requesting organization. (Other validation systems may be used, such as an authorization number if received by electronic mail.) |

| 11. | Requested Work: | A description of the requested work and a justification for the request if it is for other than maintenance. |

| 12. | Special Instructions: | Any special permits, coordination, outages, or other requirements the originator is aware of that apply to this work. |

| 13. | WICN: | Work Input Control Number, a unique identifier assigned by the facilities maintenance organization to identify the request for subsequent tracking by the facilities maintenance organization. |

| 14. | Date Rcvd: | The date the request is received by the facilities maintenance organization's work reception desk. |

| 15. | W.O. #: | Work Order Number, the identifying number of the work order that the requested work is being accomplished under, if applicable. |

| 16. | Labor: | Estimated labor cost for the work. |

| 17. | Material: | Estimated material cost for the work. |

| 18. | Equipment: | Estimated equipment cost for the work. |

| 19. | Other: | Estimated other costs for the work. (This could include items such as one-time contracts for portions of the work.) |

| 20. | Total Est: | Total estimated cost. |

| 21. | Approval Status: | An indicator to document the fact that the work: (a) Is approved and will be performed by the facilities maintenance organization using the funds cited in block 23, (b) is approved subject to funding by the originator, or (c) is disapproved. |

| 22. | Comments: | Additional information, such as the reason for disapproval or a note regarding sketches or attachments to a returned estimate. |

| 23. | Fund Citation: | A fund citation or accounting data to cover the work. |

| 24. | Authorizing Signature: | Signature by competent authority granting approval to charge the funds in the Fund Citation data field for the work. |

| 25. | Date: | The date the authorizing signature is affixed. |

| 26. | Internal Status: | This information is not shown on the sample printed form, but should be contained in the CMMS database. It is a series of status tracking data fields used by the facilities maintenance organization. The status data includes the date and current processing status of the request as well as who has the request for action and what actions have been completed. |

D.2.3 Instructions for Use. The Request for Facilities Maintenance Services should be automated as part of the CMMS. However, because it originates with a customer, entry into the CMMS may not take place until after it is submitted by the originator and received by the work control center. Where electronic mail is available or customers have network access to the CMMS, it may be possible to automate the submission and initial data entry. The form is used as follows:

a. The originator provides the required information for data fields 1 through 12, 23, 24, and 25. The remaining fields are the responsibility of the facilities maintenance organization. Normally, fields 1 through 12 are filled in at the time of the initial submission. The Estimate Only "Y" block is selected if the originator is requesting only a cost estimate.

b. When the facilities maintenance work reception desk, in the Work Control Center (WCC), receives the request, the work reception clerk enters the date received and assigns a work input control number for tracking purposes.

c. The WCC (typically the work reception clerk) screens the request to determine what action is required. If the request is for work properly accomplished as a TC ticket, the WCC prepares a TC ticket and notes this in the Work Order block (15) and the Comments block (22). The WCC notifies the originator by completing the Approval Status (21) and returning a copy to the originator.

d. If the request is for an estimate only, the WCC forwards it to the estimators. When the P&Es complete the estimate, they fill in the Labor, Material, Equipment, Other, and Total blocks (16-20) and return it to the WCC. The WCC notifies the originator by returning a copy of the request with the estimate data. The returned package may include the detailed estimate and job plan prepared by the P&E, a request for funds, and a tentative or conditional scheduling window for the work.

e. If the request is for the performance of work that requires planning and estimating and it has received preliminary approval, the WCC forwards it to the P&Es for detailed job planning and estimating. When the P&Es complete the job package (including a work order), they return it to the WCC. The WCC then forwards it to the proper official for final review and approval.

f. If approved, the WCC completes the Work Order #, Approval Status, and Comments blocks (15, 21, and 22) and notifies the originator. If the originator should fund the job, it proceeds as a request for estimate as discussed in section D.2.3d. The reasons for originator funding should be stated in the comments. If the originator provided funding data for the request, it is entered into the shop load plan for execution when final approval is given.

g. If the request is disapproved, the WCC enters this in the Approval Status and Comments blocks (21 and 22) and notifies the originator. Because disapprovals can cause customer discontent, the WCC should ensure review by an appropriate manager in the facilities maintenance organization before notifying the originator.

h. The Internal Status data elements (item 26, not shown on the form) are used to track the status and progress of the request. As the request moves through the facilities maintenance management process and facilities maintenance organization, the WCC enters the date, status, and responsible action party. This provides a history of the request.

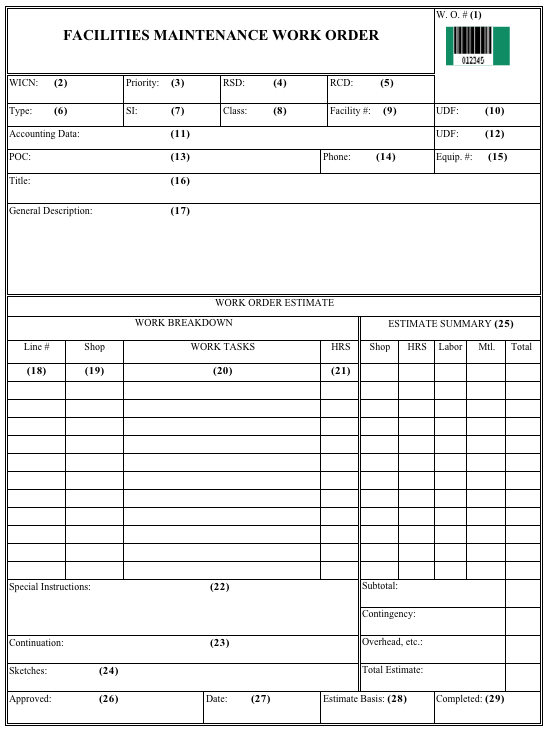

D.3 Facilities Maintenance Work Order (Paper or Electronic)

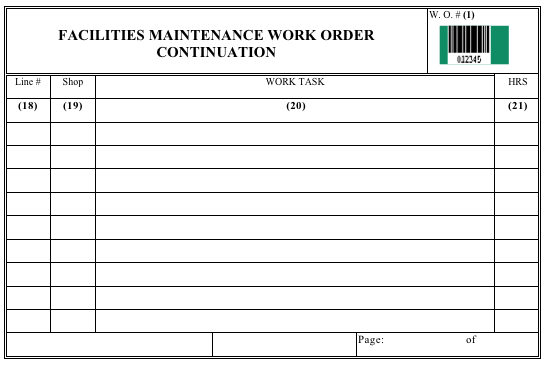

D.3.1 Sample Form: Facilities Maintenance Work Order. Figure D-3 is a sample facilities maintenance work order form. The form is generic, but it illustrates the information recommended for a work order. The form shown in Figure 10-2, Equipment/Discrepancy Classification Form, also generic, can be used to identify work items, usually Trouble Call work, that do not have identification numbers. Using these standardized equipment terms and discrepancies will allow the work to be coded into the CMMS for data integration and analysis. Figure D-4 is a sample continuation sheet that supports the sample facilities maintenance work order form. Figure D-5 is a sample facilities maintenance work order material/equipment requirements form that can be used to document the materials and equipment required for the work order. The actual forms used should be tailored to the Center's needs and the CMMS used.

Figure D-3 Sample Form: Facilities Maintenance Work Order

Figure D-4 Sample Form: Facilities Maintenance Work Order Continuation Sheet

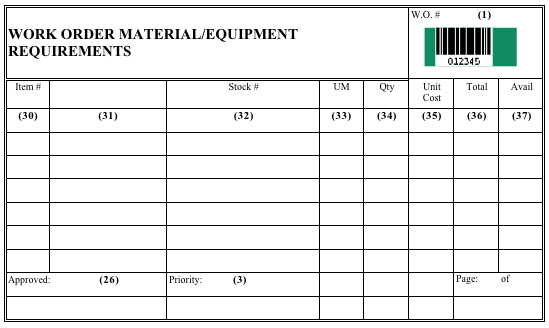

Figure D-5 Sample Form: Facilities Maintenance Work Order Material/Equipment Requirements

D.3.2 Data Elements

| 1. | W. O. #: | Work Order Number, this number is used to track the work order and related actions throughout the life of the work order. On the sample, it is shown both as a bar code and as numerals. One work order may be issued to cover more than one work request. |

| 2. | WICN: | Work Input Control Number, a unique number assigned by the facilities maintenance organization to identify a request for facilities maintenance services for subsequent tracking of the request. One work request may result in more than one work order. |

| 3. | Priority: | The work priority rating. This may not be the same as the priority requested by the originator on the Request for Facilities Maintenance Services form. |

| 4. | RSD: | Required Start Date, the date work can or will start as applicable. This may be determined by the availability of the facility or the time required to meet the completion date. |

| 5. | RCD: | Required Completion Date, the required completion date for the work order. Where possible, this should be the same date as on the Request for Facilities Maintenance Services form. |

| 6. | Type: | The type of work as defined in section 1.5.1.c. |

| 7. | SI: | Special interest, an indicator as defined in section 5.5.4.3.d or locally. |

| 8. | Class: | Class, a locally definable descriptor for the work that can be used for analysis of work. |

| 9. | Facility #: | The facility number as recorded in property records. |

| 10. | UDF: | User definable field, a locally definable descriptor for the work that can be used for analysis of work. |

| 11. | Accounting Data: | The applicable accounting data for the work order. |

| 12. | UDF: | User definable field, a locally definable descriptor for the work that can be used for analysis of work. |

| 13. | POC: | Point of Contact, the name of the customer organization's POC responsible for this request. This is needed by the shops for coordination purposes. |

| 14. | Phone: | The telephone number for the POC. |

| 15. | Equipment #: | The equipment inventory number, as recorded in property records. This field applies only when the work is to be done on an equipment item. It can be the principal equipment item if the work order covers multiple equipment items. |

| 16. | Title: | Short descriptive title of the work order. |

| 17. | General Description: | A narrative description of the scope and intent of the work order. |

| 18. | Line #: | Sequential task numbers. |

| 19. | Shop: | Shop, the shop or craft group planned to perform the task. |

| 20. | Work Tasks: | A statement of each task required to complete the work order. |

| 21. | HRS: | Hours, the amount of labor required to complete the task. Normally, this is based on an estimating standard. |

| 22. | Special Instructions: | Any special instructions or directions not covered in the listed work tasks. |

| 23. | Continuation: | Statement that material and continuation sheets are provided where all tasks and material/equipment requirements are not entered on this form. Continuation sheets are forms that contain the work order number and additional work breakdown lines (see Figure D-4). |

| 24. | Sketches: | Reference to drawings or sketches. Ideally, drawings would be from a graphics information system or CADD system that is integrated with the CMMS. The drawings, sketches, and other graphics would be prepared, printed, and attached to the work order. |

| 25. | Estimate Summary: | This multifield section is a summary of the work order estimate by shop, listing the estimated hours, labor cost, material cost, and total costs, together with any overall reservations for contingencies, overhead, or surcharges, and the total estimate. |

| 26. | Approved: | Signature authorizing release and execution of the work order. |

| 27. | Date: | Date the work order is approved for execution. |

| 28. | Estimate Basis: | A field to identify the basis of the cost estimate or the estimating standard used. |

| 29. | Completed: | The date the work order is completed. |

| The work order material/equipment requirements form (Figure D-5) includes the following additional data elements: | ||

| 30. | Item #: | Sequential number of items on the requirements list. |

| 31. | Stock #: | The stock number of the required item. This may be a local stock number, a National Stock Number (NSN), a manufacturer's part number, or other identifier. If other than a local stock number or NSN, supporting information (e.g., the identity of the manufacturer) should be given with the description. |

| 32. | Description: | Nomenclature, supplier, and other descriptive data of the required item or equipment. |

| 33. | UM: | Unit of measure (e.g., lf, ea, gal, hr). |

| 34. | Qty: | Quantity required. |

| 35. | Unit Cost: | Unit cost of the item. |

| 36. | Total: | Total cost of the specified quantity of the item. |

| 37. | Avail: | Availability of the material. Enter the material delivery due date or a symbol to show that the material is in stock and ready for issue to the shops. |

D.3.3 Instructions for Use

a. The facilities maintenance work order form provides the work authorization and direction to the shops. It also documents the work phases and cost estimate. Except for the accounting data and approval signatures, the work order form, continuation form, and material/equipment requirements forms usually are prepared by the P&Es. Normally, the accounting data is assigned as part of the final approval process. The use of a bar code on the work order form, the work order continuation form, and the material/equipment requirements form speeds subsequent processing, material issue, and closing of the work order while reducing data entry errors. (Most CMMSs support printing of bar codes.)

b. After the work order has final approval, it is distributed to the shops, the material manager, the customer (in the case of customer-requested work), and others as determined by Center policy. Distribution may be accomplished electronically if e-mail is available, or if the CMMS work order database is shared on a network. The form shown contains all information concerning the work order and goes beyond the information requirements of many users of the form. For example, the material manager may not need the detailed task breakdown. With electronic distribution, it is possible for users to receive only necessary extracts of the data.

c. When the work order is completed, it is closed, and the information is added to the facility history files. The completion date is recorded and reported to the work control center.

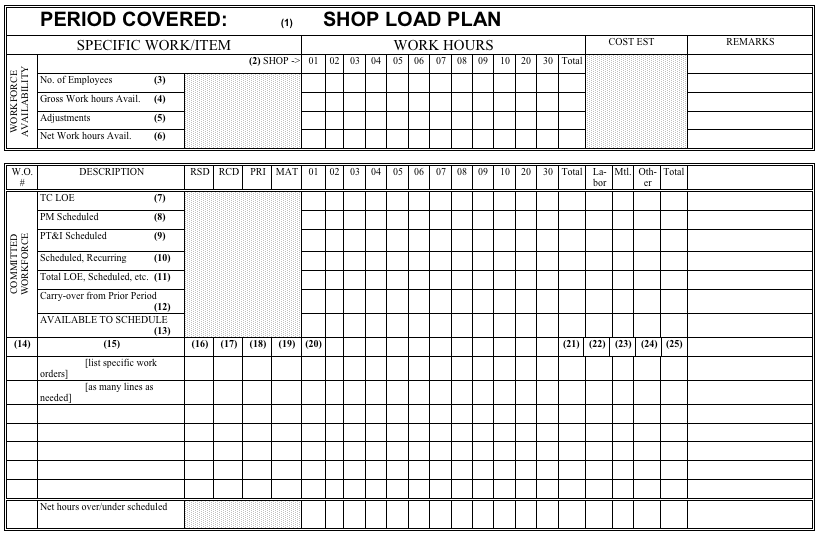

D.4 Shop Load Plan

D.4.1 Sample Form: Shop Load Plan. Figure D-6 (see reproducible and enlargeable page at the end of this appendix) is a sample shop load plan form. The CMMS used by the Center should support computer-aided scheduling, including interactive labor and other resource scheduling and schedule balancing. The shop load plan should be automated as a standard report in the CMMS. A single database should support all three levels of scheduling (i.e., shop load plan, master schedule, and shop schedule) in a networked system. While it is possible to examine the shop load plan on a video display terminal, the practical limitation on the number of lines and columns that can be displayed at one time makes a printout on wide paper convenient for use by managers.

D.4.2 Data Elements. The following data elements are shown on the Shop Load Plan. The information either is contained in the CMMS database or is derived from the CMMS database. It is defined below as an aid to understanding the schedule format. The only item that should require entry in the scheduling process is for the scheduling period. The rest of the information is based on other data entered in the CMMS during the work reception and planning process or extracted from other databases, such as labor accounting.

| 1. | Period Covered: | The period this schedule considers. Normally, for the Shop Load Plan, this is a quarter. However, the immediate next three months may be subdivided into a one-month short-term and a two-month midterm load plan for additional scheduling control. |

| 2. | Shop: | The shop or craft group being scheduled, e.g., carpenters. (The sample form shows 12 shops; this should be adjusted to meet local needs.) |

| 3. | No. of Employees: | The average number of employees available in each shop. |

| 4. | Gross Work Hours Avail: | The total number of work hours available in each shop during the schedule period. |

| 5. | Adjustments: | The number of work hours that will not be available in each shop for facilities maintenance work due to leave, training, jury duty, and similar nonproduction activities. (This may be presented on more than one line if a line for each type of adjustment is desired.) |

| 6. | Net Work Hours Avail: | The net work hours available in each shop for facilities maintenance work, computed as item four less item five. |

| 7. | TC LOE: | Trouble Call ticket LOE, the number of hours allocated by shop for jobs issued under TC tickets. Usually, this is based on experience. |

| 8. | PM Scheduled: | The number of hours for scheduled PM work by shop. This is determined from the PM schedule contained in the CMMS database. |

| 9. | PT&I Scheduled: | The number of hours for scheduled PT&I work by shop. This is determined from the PT&I schedule contained in the CMMS database. |

| 10. | Scheduled, Recurring: | The number of hours by shop for other scheduled recurring work. This may be determined from the CMMS database. It may be presented on more than one line if grouped, such as by type or work order. |

| 11. | Total LOE Scheduled: | Total hours committed to items 7, 8, 9, and 10 above. |

| 12. | Carryover from Prior Period | Work scheduled or started in the prior period, but not completed and, thus, carried over to this period. This may be automatically computed by comparing work order labor estimates against labor charges to date. |

| 13. | Available to Schedule: | Net Work hours available (6) less item Total LOE Scheduled (11), and Carryover (12). This is the workforce available for scheduling new work orders. |

| 14. | W.O. #: | Work Order number for each work order listed. |

| 15. | Description: | An entry giving a short title for each work order. The number of hours estimated for each shop for the work order follows on the same line. |

| 16. | RSD: | Requested start date for the work order. |

| 17. | RCD: | Required completion date for the work order. |

| 18. | PRI: | Priority of the work order. |

| 19. | MAT: | Material status indicator. Normally, this block contains the date on which the required material is expected to be available, or that the material is available. This is the overall status of the field "Avail" on the Work Order Material/Equipment Requirements form, Figure D-5. |

| 20 | Work hours: | The estimated work hours for the work order for each shop. |

| 21. | Total: | The total labor hours for the work order for all shops. |

| 22. | Labor: | Estimated total labor cost for the work order. |

| 23. | Mtl: | Estimated total material cost for the work order. |

| 24. | Other: | Estimated total other cost for the work order. This would include items such as equipment rentals and contracted services. |

| 25. | Total: | The total cost for the work order. |

D.4.3 Instructions for Use

a. Normally, the shop load plan is prepared quarterly. However, shop load plans should be prepared and maintained looking 18 months into the future. The last period should include all work that is in an "estimated and approved but unscheduled" status. A Center also may wish to extract a short-term (next month) and a midterm (following two months) shop load plan for closer work scheduling and management. After final approval of a work order, it is assigned to a shop load plan. Normally, this level of scheduling is done by a senior maintenance planner, not in the shop's organization. This starts the work performance phase and triggers material acquisition to ensure that the required material is available for the assigned start period. Approved work orders remain in the shop load plan until completed or canceled.

b. The primary purpose of the shop load plan is to provide for orderly scheduling of work in accordance with the Center's mission priorities, to assist in resource scheduling and management, and to provide senior managers with information on pending work. It also provides a valuable tool for evaluating the workforce skill mix against workload requirements. If the shop load plan consistently shows a significant amount of overscheduling or unscheduled backlog in a shop coupled with underscheduling in another shop, realignment of workforce assets from the underscheduled to the overscheduled shop may be in order.

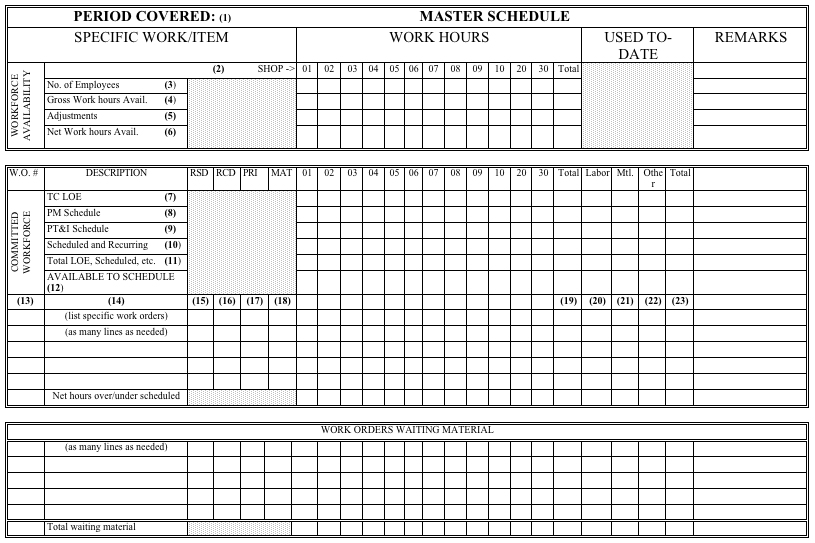

D.5 Master Schedule

D.5.1 Sample Form: Master Schedule. Figure D-7 (see reproducible and enlargeable page at the end of this appendix) is a sample form for a master schedule. The master schedule is based on the shop load plan. However, its focus is on scheduling work performance to a specific week and tracking material status of work orders that are due for master scheduling in the future according to the current and approaching shop load plans. Normally, master schedules are prepared covering six to ten weeks into the future. Jobs with long-lead-time material requirements may be scheduled further in the future. Of special interest is the Work Orders Waiting Material section. This is used to highlight the material status of work orders waiting material that need to start during the master schedule period covered.

D.5.2 Data Elements. The following data elements are shown on the master schedule form. As with the shop load plan, the information either is contained in the CMMS database or is derived from the CMMS database by manipulation and calculation. The data elements are defined below as an aid to understanding the schedule form. The only data that should require entry in the scheduling process is for the period during which the work order is being scheduled (normally, the specific workweek). The rest is based on other data entered in the CMMS during the work reception and planning process, the material management process, or extracted from other databases such as labor accounting.

| 1. | Period Covered: | The period this schedule considers. Normally, for the master schedule, this is a workweek. |

| 2. | Shop: | The shop or craft group being scheduled; e.g., shop 01, carpenters. |

| 3. | No. of Employees: | The average onboard workforce in each shop during the schedule period. |

| 4. | Gross Work hours Avail: | The total number of work hours in each shop available during this period. |

| 5. | Adjustments: | The number of work hours that will not be available for facilities maintenance work due to leave, training, jury duty, and similar nonproduction activities. This may be presented on more than one line if a line for each type of adjustment is desired. |

| 6. | Net Work hours Avail: | The net available work hours for facilities maintenance work |

| 7. | TC LOE: | TC ticket LOE, the number of hours allocated for jobs, usually issued under TC tickets. Usually, this is based on experience. |

| 8. | PM Scheduled: | The number of hours for scheduled PM work. |

| 9. | PT&I Scheduled: | The number of hours for scheduled PT&I work. |

| 10. | Scheduled & Recurring: | The number of hours for other scheduled or recurring work. This may be presented on more than one line if grouped, such as by type or work order. |

| 11. | Total LOE, Scheduled: | Total hours committed to items 7, 8, 9, and 10. |

| 12. | Available to Schedule: | Net work hours available (item 6) less item 11. This is the workforce available for scheduling specific work orders. |

| 13. | W.O. #: | Work order number for each specific work order listed. |

| 14. | Description: | Entry giving a short title for each work order. Also, the number of work hours scheduled for the work order by each shop during this schedule period is entered under the shop number on the same line. |

| 15. | RSD: | Requested start date for the work order. |

| 16. | RCD: | Requested completion date for the work order. |

| 17. | PRI: | The work order priority rating. |

| 18. | MAT: | Material status indicator. Normally, this entry is the date on which material required for the work order is expected to be available or a code indicating that the material is currently available. |

| 19. | Total: | Total labor hours for the shops. |

| 20. | Labor: | Expended labor hours. The total labor hours used or scheduled for the work order prior to this schedule period. |

| 21. | Mtl: | Cumulative material cost of material used for work order. |

| 22. | Other: | Cumulative costs of other than labor and material used for the work order. This includes such items as equipment rentals and contracted services. |

| 23. | Total: | Cumulative total cost. |

D.5.3 Instructions for Use

a. The master schedule is used to direct and coordinate the execution of work in the shops. It provides the coordinating linkage between the shops on jobs involving more than one shop, and it highlights the material status of pending work orders. Normally, it is maintained under the direction of the shop supervisor working in close coordination with the other shop supervisors and the maintenance planners. Work is scheduled by assigning it to a specific workweek; the automation program used should perform all necessary calculations, including computing estimated carryover work and resources expended (or projected to be expended) up to the period under consideration.

b. It is essential for the master schedule to give close attention to balancing the work to each shop to ensure that all forces are productively employed. To this end, the master scheduler will assign labor hours to each scheduled job within available workforce and job-phasing requirements.

c. While it is possible to examine the master schedule on a video display terminal, the practical limitation on the number of lines and columns that can be displayed at one time makes it difficult to see all work that is subject to scheduling. Accordingly, printouts on wide paper and wall-mounted scheduling boards normally are used to display job status.

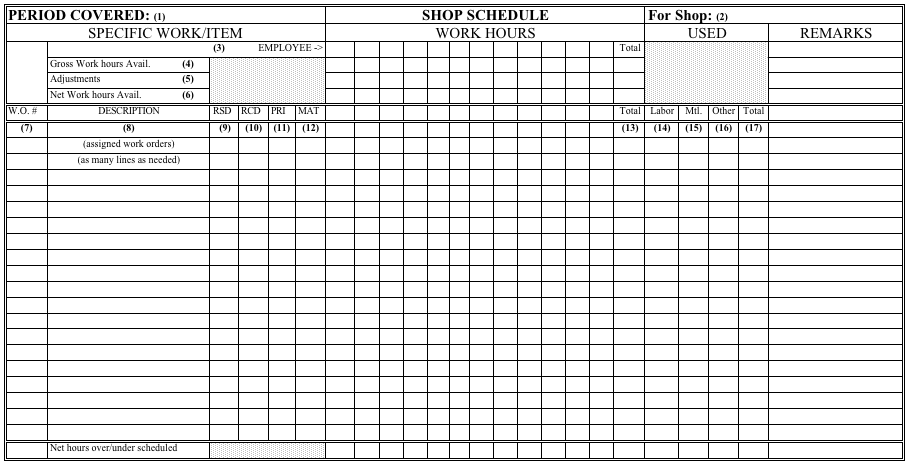

D.6 Shop Schedule

D.6.1 Sample Form: Shop Schedule. A form for a shop schedule is provided as Figure D-8 (see reproducible and enlargeable page at the end of this appendix). The shop schedule provides the day-to-day scheduling/assignment of workers and equipment to work orders. It is used by the shop supervisor as an aid in scheduling personnel and shared equipment assets.

D.6.2 Data Elements. The following data elements are shown on the Shop Schedule form. The information either is contained in the CMMS database or is derived from the CMMS database by manipulation and calculation. The data elements are defined below as an aid to understanding the schedule form. The only data elements that should be entered during the scheduling process are the assigned hours for each work order and employee being scheduled. The remaining data elements should be provided by the computer based on other data entered in the CMMS during the work reception and planning process, the material management process, or extracted from other databases.

| 1. | Period Covered: | The period this schedule considers. Normally, for the shop schedule it is a specific day. |

| 2. | Shop: | The shop or craft group being scheduled; e.g., shop 01, carpenters. |

| 3. | Employee: | The name or other identifier of the worker being scheduled. |

| 4. | Gross Work hours Avail: | The total number of work hours available for each worker during this period, normally eight. |

| 5. | Adjustments: | The number of work hours that will not be available for facilities maintenance work due to leave, training, jury duty, and similar nonproduction activities. This may be presented on more than one line if a line for each type of adjustment is desired. |

| 6. | Net Work Hrs. Avail: | The net available work hours for each employee for facilities maintenance work. |

| 7. | W.O. #: | Work order number for each work order listed. |

| 8. | Description: | An entry giving a short title for each work order. The hours assigned to each employee for each work order number follows on the same line under the employee's identification. |

| 9. | RSD: | Requested start date for the work order. |

| 10. | RCD: | Requested completion date for the work order. |

| 11. | PRI: | The work order priority rating. |

| 12. | MAT: | Material status indicator. Normally, this is a code or symbol indicating that the material is currently available. |

| 13. | Total: | Total hours for all employees. |

| 14. | Labor: | Cumulative labor hours for the work order prior to this schedule period. This information is provided as part of the labor distribution/timekeeping process. |

| 15. | Mtl: | Cumulative cost of material used for the work order. |

| 16. | Other: | Cumulative cost of other than labor and material used for the work order. This includes such items as equipment rentals and contracted services. |

| 17. | Total: | Cumulative total cost. |

D.6.3 Instructions for Use. The shop supervisor, in scheduling and managing craft personnel, uses the shop schedule. It is typically prepared on a weekly basis for each day of the following week, based on jobs scheduled in the master schedule. The shop supervisor enters the hours each employee is scheduled to work on each assigned job for each day. The workforce availability is determined from leave, training, and related activities that are scheduled through the shop supervisor.

Figure D-6 Sample Form: Shop Load Plan

Figure D-7 Sample Form: Master Schedule

Figure D-8 Sample Form: Shop Schedule

| TOC | Change History | Preface | Chapter1 | Chapter2 | Chapter3 | Chapter4 | Chapter5 | Chapter6 | Chapter7 | Chapter8 | Chapter9 | Chapter10 | Chapter11 | Chapter12 | AppendixA | AppendixB | AppendixC | AppendixD | AppendixE | AppendixF | AppendixG | AppendixH | AppendixI | ALL | |

| | NODIS Library | Program Management(8000s) | Search | |

This document does not bind the public, except as authorized by law or as incorporated into a contract. This document is uncontrolled when printed. Check the NASA Online Directives Information System (NODIS) Library to verify that this is the correct version before use: https://nodis3.gsfc.nasa.gov.