Procedural

Requirements

Effective Date: October 07, 2015

Expiration Date: October 06, 2025

|

NASA Procedural Requirements |

NPR 8831.2F Effective Date: October 07, 2015 Expiration Date: October 06, 2025 |

| | TOC | Change History | Preface | Chapter1 | Chapter2 | Chapter3 | Chapter4 | Chapter5 | Chapter6 | Chapter7 | Chapter8 | Chapter9 | Chapter10 | Chapter11 | Chapter12 | AppendixA | AppendixB | AppendixC | AppendixD | AppendixE | AppendixF | AppendixG | AppendixH | AppendixI | ALL | |

8.1.1 During the course of new construction, major repair, or rehabilitation of facilities, it is not unusual to discover installed systems or equipment that are out of alignment and balance, that contain latent defects from manufacturing and installation, or that simply do not operate as intended. For example, evaluations of new construction of at least two NASA Centers revealed that 85 to 100 percent of the rotating equipment was misaligned, out of balance, or contained defective bearings. These types of systems or equipment defects result in premature failures, which require unbudgeted corrective action by O&M staff. Given today's tight facilities O&M budgets, each Center shall, for new construction, major repair, or rehabilitation of facility projects, employ an acceptance process that includes the use of PT&I to verify system and equipment condition. This should be done prior to acceptance of the work and the contractor's departure from the job site and turning the keys over to the operations and maintenance staff. The expected result is a facility that is safer and is less costly to maintain. The acceptance process can achieve these results by:

a. Ensuring there are no latent factory or installation defects.

b. Verifying building systems and equipment performance through functional performance testing.

c. Providing full documentation and training for the O&M staff to improve their performance.

8.1.2 Building and equipment acceptance is one element of a larger, more comprehensive construction quality program known as "commissioning." Currently, there are four variations of commissioning being practiced: Traditional commissioning, total building commissioning, total building recommissioning, and NASA's customized application of a portion of commissioning called, Reliability Centered Building and Equipment Acceptance (RCB&EA).

8.1.3 Traditional Commissioning. Traditional commissioning involves performing random tests and checks on facility systems to ensure that they are properly balanced, functionally operational, and comply with the design intent. It systematically checks operating parameters such as pressure, temperature, minimum and maximum air flow, lighting levels, electrical amperage and voltage, torque, fluid volumes, and other thermodynamic measures at key locations, as well as balanced conditions. It is a method of acceptance testing that, when performed on a random basis at random sampling points, checks to ensure that the outcome indices at those points are in compliance with the outcome requirements stated in the design specification. Although the method ensures that the installation meets the design requirements, traditional commissioning reflects the conditions in a snapshot in time, specifically on the day(s) that the system is being inspected for acceptance. Also, it generally fails to emphasize the quality of the equipment installation itself, such as latent manufacturing and installation defects. Even if the installation is in compliance with the design and reflects the proper process parameters at the time of equipment acceptance, these undetected defects may result in premature equipment failure and operational and maintenance problems due to misalignment or similar conditions discovered at a later date. The problem then becomes one of many warranty issues, which, based on typical NASA history, often are inadequately enforced.

8.1.4 Total Building Commissioning. Total building commissioning is a continuous, systematic process of ensuring that facility systems are planned, designed, installed, tested, and capable of being operated and maintained to perform according to the design intent and the user's needs. Use of a third party Commissioning Agent is the preferred practice. The total building commissioning process is optimally applied to all phases of a construction projectâ?"program planning, design, construction/installation, acceptance, and postacceptance/occupancy. Commissioning team involvement begins at the earliest stages of project planning, where the team's expertise in such areas as system sizing, code compliance, maintainability, user-friendliness, product quality and reliability, ergonomics, and projected life-cycle costs are applied to the design. The commissioning staff is also involved in monitoring the quality of the construction in terms of workmanship, specification, and code compliance throughout the construction, using traditional commissioning tests and inspection procedures for quality assurance and for system acceptance. Finally, the quality team monitors the installed system following acceptance to ensure that there are no latent installation defects or degradation of system performance and operational quality. This rigorous commissioning process is intended to provide the following benefits:

a. Ensure that a new facility begins its life with systems at optimal productivity.

b. Improve the likelihood that the facility will maintain this level of performance.

c. Restore an existing facility to high productivity.

d. Ensure facility renovations and equipment upgrades function as designed.

8.1.5 Total Building Recommissioning (also referred to as LEED-O&M). The commissioning of existing buildings is known as building recommissioning and is a low-cost method to improve building performance. Over time, the efficiency of a building's systems can decline, especially if they were never commissioned or where improperly commissioned during building acceptance. Recommissioning finds and corrects equipment problems and also tunes up systems and equipment, ensuring they operate in an integrated manner. Based on energy savings, recommissioning can deliver simple paybacks that rarely exceed four years and are often two years or less. In addition to saving energy, recommissioning:

a. Extends equipment life and reduces premature equipment failure.

b. Reduces operating and maintenance costs.

c. Decreases risk and increases the asset value of the building.

d. Helps ensure a healthy, comfortable, and productive working environment for occupants.

8.1.6 Recommissioning existing buildings helps to restore and improve the original intended operating performance. The U.S. Green Building Council (USGBC) has developed a recommissioning program for existing buildings known as LEED-O&M. Similar to the LEED-BD&C program, LEED-O&M provides owners and operators of existing buildings a method to implement sustainable operations and maintenance practices and reduces the environmental impact of a building over its functional life cycle. LEED-O&M requires that existing building commissioning (recommissioning) be performed to verify that fundamental building systems and assemblies are performing as intended to meet current needs and sustainability requirements.

8.1.7 Retrocommissioning is another tool in the facility manager's arsenal that can be used to restore a facility to design conditions and reduce the energy consumption. It can also be used to increase the overall reliability and maintainability of the facility. Retrocommissioning is used largely in facilities that have never been commissioned. In many cases, NASA Centers are using facilities built before modern, standard commissioning practices were enabled. This led to many facilities being constructed without a commissioning process or plan being in place leading to facilities that possibly never were aligned with the design purposes of the original architects. With the many modifications performed throughout the years on facilities due to constantly changing missions, these facilities likely moved further and further from the original intent of the facility. Often projects are performed that affect one system with no regard to how it might affect other systems in the facility. For example, a lighting project might occur to upgrade to LED fixtures. The electrical personnel might not have noticed that removing light fixtures with return air openings and replacing them with fixtures without them robbed the air handling unit serving the area of return air. Additionally, the ever-decreasing maintenance budget has led to cuts being required in the scope of equipment being maintained. Due to this, issues such as incorrectly operating variable air volume dampers, misadjusted air handler sheaves, and malfunctioning exhaust fans can reduce a facility's performance and energy efficiency. Retrocommissioning is a way to realign these facilities with the original design intent.

8.1.7.1 The terms retrocommissioning and recommissioning are often used interchangeably. Retrocommissioning is usually a one-time event that is used to set a building up to be recommissioned on a periodic basis. As with the other types of commissioning, the process for retrocommissioning is largely the same. Retrocommissioning typically has a larger initial cost than other processes, such as recommissioning, due to the up-front workload of compiling diagnostic test forms, functional test forms, and other documentation for systems that were never initially developed or may be difficult to develop due to the age of the existing equipment.

8.1.7.2 It is best to implement this process utilizing a phased approach method. This is beneficial both in terms of funding levels and also various contract timing issues. With the amount of manpower involved in compiling information and performing testing that might have never been done on equipment, it can be beneficial to contract with an outside organization or company that specializes in commissioning and retrocommissioning to perform the majority of the work in larger projects. Their help can be beneficial in developing testing and certification procedures where they likely do not exist for aged equipment. The local O&M contractor can then provide support and repair services as problems are found during the process.

8.1.7.3 The first step in this process is typically the planning phase. This is largely the preparatory section of the project. In this phase the project objectives need to be clearly defined. Also, the equipment or systems that will be analyzed for function and improvements need to be listed. a. The HVAC/mechanical sections are going to be the largest systems to analyze but will also lead to the biggest effect on the bottom line cost for a particular facility. This is where the decision needs to be made if O&M personnel will be responsible for the work or if the services of an outside Commissioning Agent (CxA) will be required. Many companies now offer services of this type so it is best to look for companies that have had experience in the type of project commensurate with the facility involved, whether it is offices, laboratories, industrial areas, etc. It is wise to ensure the O&M staff is involved to provide expertise on the daily operations of the facility and the equipment. It is also a good idea to involve the local commissioning agent where available as well.

b. Once the team is assembled, the retrocommissioning plan can be developed. This plan should contain basic general building information, the objectives of the retrocommissioning project, the scope of the project, equipment and systems to be included in the project, points of contact, and team members. This plan should also contain a list of deliverables due at the end of the project. During this phase, the majority of the document collection occurs. This information should include construction drawings for original construction, as well as any/all modifications performed throughout the years. In most cases, no master drawing exists displaying the current configuration of the facility. Equipment baseline data and utility and energy usage also should be obtained. The team should also gather any control sequences of operation, previous testing, adjusting, and balancing (TAB) reports, and required key performance indicators. As a final step in the planning phase, a preinspection survey should be sent to facility occupants and managers to determine existing conditions of the facility and any ongoing issues.

8.1.7.4 The second phase is the discovery phase, which is where the field work begins in the facility. During this stage, the team performs reviews of the documents obtained in the planning phase. A facilities requirements document also can be obtained through interviews with the building occupants and/or the facility manager to determine what needs the occupants currently have in regards to the systems being evaluated (e.g., temperature and humidity requirements for special areas). This is also the phase in which the testing of the equipment selected in the project scope begins. During this phase the operation of all components of the equipment are tested, the control sequences and building automation systems are tested for validity and proper operation, and TAB work is performed if part of the scope. While this work is being performed, a list of deficiencies and improvements is generated.

8.1.7.5 The third phase is the corrections phase, which largely occurs in concurrence with the discovery phase due to the nature of the work being performed. For example, as problems are found during TAB work, some repairs have to be made in order to continue the process. This is a phase that can be broken up due to funding or personnel availability. Repairs that are required to finish the project can be funded, while additional repairs/improvements can be forestalled until funding allows with the knowledge that this will reduce the impact of the project.

8.1.7.6 The fourth and final phase is the hand-off phase, the phase in which all the deliverables are submitted, such as the final commissioning report. A good deliverable to request from the project is a redline drawing of how the system actually exists in its current state, as these types of documents are often hard to find on older systems that have undergone many modifications. Additionally, a postinspection survey should be sent to the facility occupants to find out the effectiveness of the project. All of these things can be taken in to account and a lessons-learned document should be generated at the conclusion of the project to aid in future retrocommissioning projects.

8.1.8 NASA's Building and Equipment Acceptance. NASA's application of commissioning is a customization of a portion of the traditional and total commissioning processes that NASA calls Reliability Centered Building and Equipment Acceptance. NASA recognizes that there can be substantial benefits even when commissioning concepts are applied only to the acceptance phase of a construction project. These benefits can be gained during acceptance by using available PT&I technologies in addition to traditional operational parameters to identify latent manufacturing, shipping, and installation-induced defects. Identifying and correcting these defects can reduce premature failures, increase safety and reliability, and decrease life-cycle costs. NASA's portion of the commissioning concept concentrates on facility and equipment acceptance rather than on total commissionings' cradle-to-grave detailed oversight and evaluations because of the following:

a. NASA's placing safety as a top priority.

b. The current Federal budget process and constraints.

c. NASA's emphasis on reducing life-cycle costs within available and limited resources.

d. The institution of a strong and vibrant RCM program in place Agency-wide.

8.1.9 Many of the problems, safety concerns, and associated costs inherited during the O&M phase are the result of inadequate or nonexistent standards and procedures for equipment acceptance. Thus, the focus of NASA's equipment acceptance is on ensuring that the contractor detects latent manufacturing and installation defects through an effective quality control program before final acceptance of the installation by the Government.

8.1.10 This chapter provides a brief overview of NASA's acceptance process. Refer to the NASA Reliability Centered Building and Equipment Acceptance Guide for more detailed information and extensive discussion of the subject.

8.2.1 The RCM approach takes a life-cycle view of facilities and collateral equipment and seeks to ensure that facilities and collateral equipment are properly built and installed to reduce the probability of premature failure. A key element in the transition from good design to full operation is the construction and acceptance phase.

8.2.2 Initial Planning and Design. The long-term reliability of an installation or refurbishment begins with the initial planning and design. The initial criteria and equipment design determines the inherent equipment reliability, maintainability, and supportability. Moreover, as discussed in Chapter 7, Reliability Centered Maintenance, about 95 percent of the total equipment cost is determined by the end of the planning and design phase. Even though expenditures for plant and equipment may occur later during the acquisition process, their cost is committed at an early stage. The decision to include a facility in the RCM program, including PT&I, is best made during the planning phase. As RCM decisions are made later in the life cycle, it becomes more difficult to achieve the maximum possible benefit from the RCM program. It has been estimated by NASA facilities and collateral equipment designers that the cost to make a system change once the system is built is anywhere from 10 to 1,000 times more than if the change was incorporated during the system design. Clearly, the planning and design phase of facilities and collateral equipment life cycle is the time to focus on the ability to sustain operation through the use of effective acceptance testing, proper trending, necessary maintenance, and the performance of timely repair, when needed.

8.2.3 Construction and Acceptance. Contracts for construction work at NASA Centers shall require contractor responsibility for an adequate quality control program in place for the proper installation of the facility and equipment in accordance with the design requirements.

a. Throughout the installation and at the time of acceptance, PT&I shall be performed to verify that not only is the installation acceptable, i.e., that there are no latent factory or installation defects, but also, that the required baselines are established.

b. Consequently, any contractor performing work at NASA Centers shall have an understanding of the RCM process and how it affects the project.

c. NASA contracts shall require the contractor to use personnel who are trained and certified in the appropriate PT&I technologies for acceptance testing to ensure that the results are accurate and consistent.

d. The Center's Construction Manager shall ensure that all interim testing is performed and that the results meet the specifications and are documented and included with the final acceptance documentation.

e. The Construction Manager shall ensure that the acceptance testing has been performed and determine if the acceptance testing results are within the required tolerances.

f. When all acceptance criteria have been met, the Construction Manager shall collect all of the required documentation, including all manufacturers' manuals, redline drawing, and acceptance testing data, and deliver them to the appropriate Center operations and maintenance personnel.

8.2.4 Maintenance and Operations. RCM can introduce significant savings during the Maintenance and Operations phase of a facility's life. Savings of 30-to-50 percent in the annual maintenance budget are often obtained through the introduction of a balanced RCM program. O&M personnel are ultimately responsible for the proper operation and maintenance of systems and equipment. However, how the facility and its equipment will be operated and maintained shall be considered during the planning, design, and construction phases. During these phases, maintenance and operations needs are best served by carefully and realistically identifying and defining the PT&I and PM requirements. Although the performance of maintenance and operations occurs during the operations stage of the life cycle, some preparatory activities can be carried out during the acceptance stage. These activities can include O&M personnel selection, training requirements, procedure preparation, review of specifications, and collection of baseline condition monitoring data from the Construction Manager. Refer to Chapter 7, Reliability Centered Maintenance, of this document and to the NASA Reliability Centered Maintenance Guide for Facilities and Collateral Equipment for guidance on the use of RCM during facilities operations and maintenance.

8.3.1 After construction is complete, it is important to verify that the systems and equipment are operating in accordance with the construction specifications. NASA's contracts shall accomplish this by requiring the contractor to verify, as an element of the contractor's quality control program, that the equipment specified is properly installed in accordance with design and local codes and standards, that there are no latent manufacturing or installation defects, and that individual and integrated systems and equipment operation is in accordance with the design intent. During NASA's acceptance process, individual equipment is acceptance-tested using PT&I that focuses on equipment performance and by traditional thermodynamic testing. Providing this initial baseline data for comparisons and trending allows for planning and scheduling PM or repairs in advance of failure. (See Section 8.1.4, Total Building Commissioning.)

8.3.2 Facilities contain myriad equipment and systems, from the simplest light switch to a computer-controlled air conditioning system. While all equipment can benefit from the reliability centered acceptance process, it is not always cost effective to perform an acceptance test even though one is available,. The decision to perform reliability centered acceptance should be based on the RCM techniques in the NASA RCM Guide for Facilities and Collateral Equipment and the NASA Reliability Centered Building and Equipment Acceptance Guide.

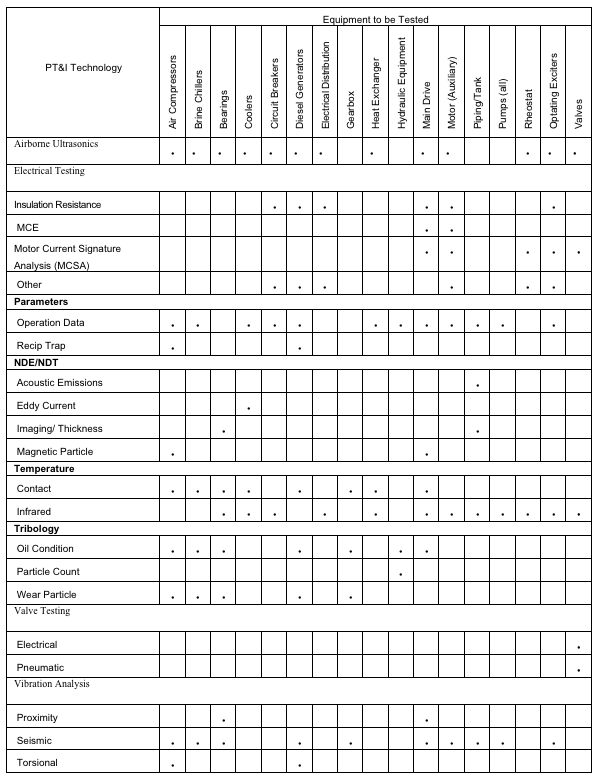

8.3.3 Table 8-1 indicates the most appropriate and commonly used PT&I technologies with respect to the most common acceptance testing applications. These PT&I tests have become some of the most effective methods for testing new and in-service equipment for hidden defects.

8.3.4 Preliminary and final acceptance testing and documentation of the test results is to be performed by the contractor as part of the contractor's QC program.

a. The contractor shall correct all detected deficiencies.

b. The condition monitoring data shall be retaken prior to acceptance of the facility and/or equipment by NASA.

c. The NASA Center shall observe and monitor this condition testing, analysis, and documentation as part of its QA program and ensure that the contractor provides all preliminary and final condition monitoring and analysis data to the Construction Manager.

8.4.1 The acceptance scope includes, but is not limited to, the following:

Table 8-1 Applicable PT&I Technologies

a. Documenting the design intent. Verifying that equipment and systems have been properly installed in accordance with the contract documentation and the manufacturer's written installation instructions.

b. Verifying the performance of each piece of equipment and each system, documenting the equipment and system performance, and ensuring that there are no latent manufacturing and installation defects.

c. Verifying that equipment has been placed into operation with the manufacturer's observation and/or approval. Verifying that adjusting, balancing, and system testing has been properly performed.

d. Assembling and submitting record drawings.

e. Training Center and/or the user's personnel in the proper operation of each piece of equipment and each system.

f. Documenting warranty start and end dates.

g. Assembling and submitting all records of code authority inspections and approvals.

h. Validating the accessibility of all work relative to the maintenance requirements of each piece of equipment and promptly advising NASA of items of noncompliance.

i. Identifying, documenting, and reporting all deficiencies of the work relative to the contract documents for tracking and correction through a deficiency-tracking program.

j. Submitting acceptance documents in an approved format.

8.5.1 Roofs. Roofs are normally constructed layer by layer and comprise many different types of materials. Moisture shall not be allowed to enter the roof structure or materials during the construction phase, as any trapped moisture will eventually degrade the roof and structure and can cause a premature failure of the roofing system. Whereas traditional roof inspections usually look for the effects of leaks, infrared thermography should be used to look for wet insulation caused by water ingress during construction, improper installation, or roof boundary failures.

8.5.2 Insulation/Building Envelope. Building insulation is installed during construction but, in most cases, prior to the building's being completed. Consequently, acceptance inspections shall occur before the walls and ceilings are completed.

a. On completion of the insulation installation, a construction detail showing the insulation material type, amount, and location shall be generated and submitted by the contractor.

b. This information shall be forwarded to the appropriate RCM official for inclusion in the maintenance database. Infrared thermography or ultrasonic mapping should be used during acceptance to identify insulation voids, insulation settling, and areas of moisture intrusion.

8.5.3 Piping Systems. Industry-standard acceptance tests for water, plumbing, and air systems first require a pressure test of all piping and fittings. During this test, an ultrasonic scan should be performed on all accessible aboveground piping to help discover any leaks. For hot water systems, after the pressure and hydro tests have been completed and after piping insulation has been installed, the system should be charged with hot water, and an infrared scan should be performed to verify insulation integrity. For steam systems, ultrasonic scans should be performed on steam traps.

8.5.4 Mechanical Systems

8.5.4.1 Vibration Analysis. Analysis of system and equipment vibration levels is one of the most commonly used PT&I techniques to determine the condition of rotating equipment and its structural stability in a system. It will detect deficiencies associated with wear, imbalance, misalignment, mechanical looseness, bearing damage, belt flaws, sheave and pulley flaws, gear damage, flow turbulence, cavitation, structural resonance, and fatigue.

a. Vibration measurements in the acceptance process shall be performed by technically qualified persons who are trained, experienced, and certified in vibration measurement.

b. Measurements shall be taken under specified operating conditions.

8.5.4.2 Test documentation, including machine layout drawings indicating vibration measurement locations, shall be submitted to, validated by, and signed by the NASA Construction Manager or other authorized official prior to final equipment acceptance.

8.5.4.3 Balance. Only 10 to 20 percent of rolling element bearings achieve their design life. Premature bearing failure is frequently due to excessive vibration caused by imbalance, misalignment, improper installation, and outside structural stresses. Acceptance testing for precision balance by the contractor at the time of equipment acceptance of motor rotors, pump impellers, and fans is one of the most critical and cost-effective techniques for achieving increased bearing life and resultant equipment reliability. NASA contracts shall require that balance measurements be performed by a technically qualified person trained, experienced, and certified in machinery balancing.

8.5.4.4 Alignment. The forces of vibration from misalignment cause gradual deterioration of seals, couplings, bearings, drive motor windings, and other rotating elements where close tolerances exist. The use of precision equipment and methods at the time of acceptance, such as reverse dial and laser systems, is necessary to bring alignment tolerances within precision standards. Precision alignment will increase the average bearing life, thus, increase machinery reliability and availability and decrease maintenance costs.

8.5.4.5 Lubrication and Hydraulic Fluids. Lubricating and hydraulic fluid analysis is performed during acceptance for three reasons: To determine the machine mechanical wear condition; to determine the fluid condition; and to determine if the fluid has become contaminated. There is a wide variety of tests to provide information on these, usually packaged by independent testing laboratories to address all three areas. In addition to assessing the condition of the fluids at the time of equipment acceptance, these tests are necessary to provide a baseline for future RCM actions.

8.5.4.6 Ultrasonic Testing. Airborne ultrasonics are used by the contractor during equipment acceptance to hear noises associated with leaks, mechanical anomalies, corona discharges, and other high-frequency events. In addition to evaluating heat exchangers, ultrasonics can be used to verify boiler casing and associated piping integrity and the proper operation of steam traps.

8.5.5 Electrical Systems

8.5.5.1 Infrared Imaging. Infrared thermography (IRT) is a noncontact technique used during acceptance to identify hot and cold spots in energized electrical equipment, large surface areas such as boilers and building walls, and other areas where "stand off" temperature measurement is necessary. More specifically, IRT is used to detect faulty conditions in transformers, motor control centers, switchgear, substations, switchyards, and power lines. In mechanical systems, IRT is used to identify blocked flow conditions in heat exchangers, condensers, transformer-cooling radiators, and pipes and to verify fluid levels in large containers such as fuel storage tanks. IRT is also used to identify misaligned drive belts and sheaves, drive couplings, motor bearing, and missing or bad insulation in roofs. Sections 8.5.1 through 8.5.3 discuss IRT's applications specific to structural systems.

8.5.5.2 Power Factor Testing. Providing the optimum power factor maximizes the efficient use of electrical power. Power factor, sometimes referred to as dissipation factor, a measure of the power loss, is a dimensionless ratio that is expressed in percentage of the resistive current flowing through insulation to the total current flowing. Consequently, the power factor test is used for making routine comparisons of the condition of an insulation system and for acceptance testing to verify that the equipment was manufactured and installed properly. The test is nondestructive, and regular maintenance testing will not deteriorate or damage insulation. Its most frequent applications are with electric motors, circuit breakers, motor control centers, switchgears, and transformers.

8.5.5.3 Insulation Resistance Testing. An insulation resistance test is a nondestructive direct current (DC) test used during acceptance to determine the condition of the insulation of electrical systems. It indicates that the insulation under test can withstand the voltage being applied. The insulation resistance is generally accepted as a reliable indication of the presence of contamination or degradation. Its most frequent applications are with motors, switchgears, motor control centers, circuit breakers, and transformers.

8.5.5.4 Insulation Oil Testing. High- and medium-voltage transformers, some high- and medium-voltage breakers, and some medium-voltage switches are supplied with mineral oil as an insulation medium. Performing oil tests prior to turnover is needed to ensure that proper oil is installed, that the necessary inhibitors have been added, and to ensure that no combustible gas products are present. Further, when insulation systems are subjected to stresses, such as fault currents and overheating, combustible gas generation can change dramatically. In most cases, these stresses can be detected early on; the presence and quantity of the individual gases can be measured and the results analyzed to indicate the probable cause of generation.

8.5.5.5 Motor Circuit Evaluation (MCE) and Motor Circuit Analysis (MCA). MCE is used during acceptance to evaluate the condition of motor power circuits. Any impedance imbalances in a motor will result in a voltage imbalance. Voltage imbalances in turn will result in higher operating current and temperatures, which will weaken the insulation and shorten the motor's life. MCA is a method of detecting the presence of broken or cracked rotor bars or high-resistance connections in end rings. While MCA is an effective test on in-service motors, it is not generally used for acceptance testing. It is, however, normally performed at initial startup so a baseline can be established.

8.5.5.6 Battery Impedance Testing. As a battery ages and begins to lose capacity, its internal impedance rises. This is a parameter that can be trended, comparing the current value with the original value taken at acceptance, with previous readings, and with other identical batteries in the same battery bank. Additionally, battery impedance testing will indicate the existence of an internal short in the battery, an open circuit in the battery, and premature aging due to excessive heat or discharges. There are no set guidelines or limits for this test. Each type, style, and configuration of battery will have its own impedance, so it is important to take these measurements during acceptance to establish a baseline.

8.5.5.7 Airborne Ultrasonics. Deficiencies in electrical systems, such as corona discharges, loose switch connections, and internal arcing in deadfront electrical connections, can all be discovered during acceptance using ultrasonic test devices. Corona discharge is normally associated with high-voltage distribution systems and is produced as a result of a poor connection or insulation problem. The discharges generally occur at random, are the precursor to a failure, and are in the ultraviolet region and not normally detectable using thermography.

8.6.1 Acceptance data shall be recorded on a formal Acceptance Data Sheet and provided to the Center Construction Manager as part of the facility or equipment documentation package. A separate sheet will be filled out for each equipment unit being evaluated during the acceptance process and may result in a voluminous total package. Refer to the NASA Reliability Centered Building and Equipment Acceptance Guide for Acceptance Data Sheet samples.

| TOC | Change History | Preface | Chapter1 | Chapter2 | Chapter3 | Chapter4 | Chapter5 | Chapter6 | Chapter7 | Chapter8 | Chapter9 | Chapter10 | Chapter11 | Chapter12 | AppendixA | AppendixB | AppendixC | AppendixD | AppendixE | AppendixF | AppendixG | AppendixH | AppendixI | ALL | |

| | NODIS Library | Program Management(8000s) | Search | |

This document does not bind the public, except as authorized by law or as incorporated into a contract. This document is uncontrolled when printed. Check the NASA Online Directives Information System (NODIS) Library to verify that this is the correct version before use: https://nodis3.gsfc.nasa.gov.