Procedural

Requirements

Effective Date: October 07, 2015

Expiration Date: October 06, 2025

|

NASA Procedural Requirements |

NPR 8831.2F Effective Date: October 07, 2015 Expiration Date: October 06, 2025 |

| | TOC | Change History | Preface | Chapter1 | Chapter2 | Chapter3 | Chapter4 | Chapter5 | Chapter6 | Chapter7 | Chapter8 | Chapter9 | Chapter10 | Chapter11 | Chapter12 | AppendixA | AppendixB | AppendixC | AppendixD | AppendixE | AppendixF | AppendixG | AppendixH | AppendixI | ALL | |

7.1.1 Refer to the NASA Reliability Centered Maintenance Guide for Facilities and Collateral Equipment for a more extensive discussion and detailed information on RCM than that provided in this document.

7.1.2 RCM is the process used to determine the most effective approach to maintenance. It involves identifying actions that, when taken, will reduce the probability of failure and that are the most cost effective. It seeks the optimal mix of proactive maintenance and reactive maintenance. RCM is an ongoing process that gathers data from operating systems' performance and uses this data to improve design and future maintenance. These maintenance strategies, rather than being applied independently, are integrated to take advantage of their respective strengths to optimize facility and equipment operability and efficiency within the given constraints.

7.1.3 The RCM philosophy employs proactive maintenance and reactive maintenance techniques in an integrated manner to increase the probability that a machine or component will function in the required manner over its design life cycle. Proactive maintenance practices includes PM and PGM. Reactive maintenance includes repair or run to fail. The goal of the philosophy is to provide the stated function of the facility, with the required reliability and availability at the lowest cost. RCM is data driven and requires that maintenance decisions be based on maintenance requirements supported by sound technical and economic justification. As with any philosophy, there are many paths or processes that lead to a final goal. This is especially true for RCM, where the consequences of failure can vary dramatically.

7.1.4 NASA has adopted a streamlined approach to the traditional or rigorous RCM process practiced in some industries. This is due to the high-analysis cost of the rigorous approach, the relatively low impact of failure of most facilities systems, the type of systems and components maintained, and the amount of redundant systems in place. Underlying NASA's RCM approach is the concept that maintenance actions should result in real benefits in terms of improved safety, required uninterrupted operational capability, and reduced life-cycle cost. It recognizes that unnecessary maintenance is counterproductive and costly and can lead to an increased chance of failure.

7.2.1 The primary principles upon which RCM is based are the following:

a. RCM is function oriented. It seeks to preserve system or equipment function, not just operability for operability's sake. Redundancy of function through multiple equipment improves functional reliability but increases life-cycle cost in terms of procurement and operating costs.

b. RCM is system focused. It is more concerned with maintaining system function than individual component function.

c. RCM is reliability centered. It treats failure statistics in an actuarial manner. The relationship between operating age and the failures experienced is important. RCM is not overly concerned with simple failure rate; it seeks to know the conditional probability of failure at specific ages (the probability that failure will occur in each given operating age bracket).

d. RCM acknowledges design limitations. Its objective is to maintain the inherent reliability of the equipment design, recognizing that changes in inherent reliability are the province of design rather than maintenance. Maintenance can, at best, only achieve and maintain the level provided for by design. However, RCM recognizes that maintenance feedback can improve on the original design. In addition, RCM recognizes that a difference often exists between the perceived design life and the intrinsic or actual design life and addresses this through the Age Exploration (AE) process.

e. RCM is driven by safety and economics. Safety shall be ensured at any cost; thereafter, cost-effectiveness becomes the criterion.

f. RCM defines failure as any unsatisfactory condition. Therefore, failure may be either a loss of function (operation ceases) or a loss of acceptable quality (operation continues).

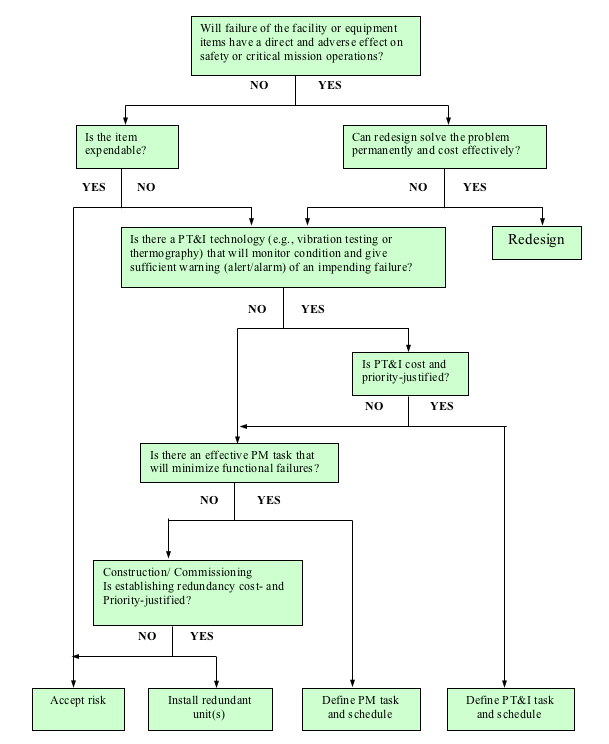

g. RCM uses a logic tree to screen maintenance tasks. This provides a consistent approach to the maintenance of all types of equipment. (See Figure 7-1.)

h. RCM tasks shall be applicable, address the failure mode, and consider the failure mode characteristics.

i. RCM tasks shall be effective, reduce the probability of failure, and be cost effective.

j. RCM acknowledges two types of maintenance tasks and run-to-failure. The tasks are interval time- or cycle-based and condition-based. In RCM, run-to-failure is a conscious decision and is acceptable for some equipment.

k. RCM is a living system. It gathers data from the results achieved and feeds this data back to improve design and future maintenance. This feedback is an important part of the Proactive Maintenance element of the RCM program.

7.3.1 Using RCM facilitates developing maintenance standards for ensuring, even in the procurement and installation phases, that a system meets its designed reliability or availability. RCM determines maintenance requirements by considering the following questions:

a. What does the system do? What is its function?

b. What failures are likely to occur?

c. What are the likely consequences of failure?

d. What can be done to reduce the probability of the failure, identify the onset of failure, or reduce the consequences of the failure?

7.3.2 Figure 7-1 provides a decision logic tree for use in RCM analysis to determine the type of maintenance appropriate for a given maintainable facilities equipment item. Note that the logic, as presented, results in a decision in the bottom blocks concerning whether a particular piece of equipment should be reactively maintained ("Accept Risk" and "Install Redundant Units"), PMed ("Define PM Task and Schedule"), or predictively maintained ("Define PT&I Task and Schedule").

7.4.1 Failure is the cessation of proper function or performance. RCM examines failure at several levels: the system level, subsystem level, component level, and sometimes even the parts level. The maintenance approach shall be based on a clear understanding of the consequences of failure at each level. For example, a failed lamp on a control panel may have little effect on overall system performance. However, several combined, minor components in degraded conditions could collectively cause a failure of the entire system.

7.4.2 Identify the System Functions. This step involves examining the capability or purpose of the system. Some items, such as a circulating pump, perform an on-line function (constantly circulating a fluid); their operational state can be determined immediately. Other items, such as a sump pump, perform an off-line function (intermittently evacuating a fluid when its level rises); their condition can be ascertained only through an operational test or check. Functions may be active, such as pumping a fluid, or passive, such as containing a fluid. Also, functions may be hidden, in which case there is no immediate indication of a failure. This typically applies to an emergency or protective system such as a circuit breaker that operates only in the case of a short circuit (electrical failure of another system or component).

7.4.3 Identify Failures. The proactive approach to maintenance analysis identifies potential system failures and ways to prevent them. Proactive maintenance, along with human observations during normal operations or maintenance tasks, also identifies prefailure conditions that indicate when a failure is imminent. (The latter is a basis for selecting PT&I applications.) Table 7-1 is a list of failure codes that may be used to identify recurring problems by category. These will provide a means of identifying areas, systems, and equipment where root cause failure or other proactive analysis may be applied. The CMMS and work order form shall include fields for failure codes to maintain historical data.

Figure 7-1 Reliability Centered Maintenance (RCM) Decision Logic Tree

Table 7-1 Failed Equipment Codes

| CATEGORY | CODE | CATEGORY | CODE | CATEGORY | CODE | ||

|---|---|---|---|---|---|---|---|

| Drain | DRAN | Power supply | PSPL | ||||

| Engine | ENGN | Pressure switch | PSWC | ||||

| Elevator | LVTR | Pulley | PULL | ||||

| EMCS | EMCS | Pump | PUMP | ||||

| Bearings | BRGS | Enclosure | NCLS | Regulator | RGLT | ||

| Belts | BLTS | Evaporator | EVAP | Rheostat | RSTT | ||

| Breaker | BRKR | Fastener | FSNR | Roof | ROOF | ||

| Cable, power | CABL | Filter | FLTR | Seal | SEAL | ||

| Capacitor | CPTR | Flashing | FLSH | Shell | SHLL | ||

| Commutator | CMTR | Gear | GEAR | Shaft | SHFT | ||

| Compressor | CPRS | Generator | GNTR | Starter | STRT | ||

| Computer | CPTR | Humidistat | HSTT | Stator | STTR | ||

| Condenser | CNDN | Impeller | IMPL | Support/base | SPPT | ||

| Connector | CNTR | Inductor | NDCT | Switch | SWCH | ||

| Controller | CNTL | Light | LGHT | Thermistor | THMS | ||

| Cooler, swamp | COLS | Logic, PLC | PLOG | Timer | TMER | ||

| Cooling Coil | COIL | Lubrication | LUBE | Transformer | TRAN | ||

| Coupling | CPLG | Meter | METR | Tube, boiler | TUBE | ||

| Crane | CRNE | Motor | MOTR | Valve | VLVE | ||

| Damper | DMPR | Packing | PCKG | Winding | WNDG | ||

| Door, power | PDOR | Pipe | PIPE | Window | WIND | ||

| Piston | PSTN |

7.4.4 Identify the Consequences of Failure. The most important consequence of failure is a threat to safety. Next, is a threat to the environment or mission accomplishment (operating capability). The RCM analysis should pay close attention to the consequences of the failure of infrequently used, off-line equipment and hidden function failures. Also, it should consider the benefit (reduced consequences of a failure) of redundant systems.

7.4.5 Identify the Failure Process. Determining the methods and root causes of failures provides insight into ways to detect or avoid failures. The examination, which investigates the cause of the problem and not just its effect, should consider factors such as wear, overload, fatigue, or other processes.

7.4.6 Verify the System. Before efforts are expended on a system, it is important to verify that the system was installed or is being used as originally designed. This review of the design and maintenance support information may reveal the root cause of a past or anticipated problem. Although the existing design may have been correct, the installation, while functional, may have been improper, or there may have been latent manufacturing defects. These deficiencies should be discovered and corrected by the contractor during the acceptance process, before the equipment is accepted by the Government and the contractor leaves the job site. If, after acceptance, the installation is still under warranty, the problem may be resolved without an additional expenditure of NASA resources. Changes in the intended use of equipment can also create problems leading to excessive wear and premature failure.

7.4.7 Modify the System. Redesigning the system to eliminate the weakness may be the most desirable solution since it can eliminate a potential cost. However, redesign may not be possible in many facilities maintenance situations.

7.4.8 Define the Maintenance Task. The following factors should be considered when defining the maintenance task:

a. Once it has been determined that the failure of a facility or equipment item will have a direct effect on the safety or mission operation and redesign cannot improve its reliability, then a PT&I, PM, or PGM task or combination of tasks should be identified that will lessen the chances or consequences of a failure. Where applicable, predictive technologies should be used to monitor the condition of the facility or equipment. If the technology or local expertise is not available, a preventive maintenance program is normally applicable.

b. Maintenance tasks can be time directed (e.g., every 8 weeks), condition directed (e.g., when pH is greater than 7.3), or inspection directed (e.g., if a component is found worn). A particular bearing can be monitored for vibration (PT&I), routinely lubricated and checked (PM), or replaced prior to its expected failure point (PGM).

c. The total system should be evaluated to ensure that all the individual tasks maintain the system at the same degree of reliability. The tasks should also be grouped to ensure that they can be executed in the most economical manner. This may be accomplished by grouping multiple tasks on an individual equipment item or by grouping like tasks on numerous items of equipment in a given facility or zone of several facilities.

7.4.9 Install Redundant Unit(s). Situations exist where, despite all effective maintenance efforts, the risk of a potential failure is still unacceptable. Very critical areas such as a mission control or communication center may require uninterrupted facility equipment to maintain power or climatic control. The criticality may preclude even shutdown for maintenance purposes. In these situations, redundancy is justified and recommended. The problem may be corrected through additional distribution or switching of power or ventilation ducts, provided the system can accept the additional loads. The need for a redundant system should be determined before the situation becomes critical. This will preclude premature failure resulting from a lack of maintenance on a system that cannot be shut down. Often, the loss to the mission would be of much greater cost than the redundant system. This need requires close coordination and communication with the customer.

7.4.10 Accept the Risk. It may be that further safety or environmental precautions are not possible or that the economic or operational cost of a failure is insignificant or substantially less than the cost of any effective redesign or maintenance procedure. In the former case, the accepted risk should be identified and quantified, and all parties concerned should be made aware of the risk and appropriate recovery procedures. In the latter situation, it does not make business sense to implement a PM or PGM task. This philosophy is known as "run-to-failure."

7.5.1 Safety. Per NPD 8700.1, NASA Policy for Safety and Mission Success, NASA policy is to "Avoid loss of life, personal injury or illness, property loss or damage, or environmental harm from any of its activities and ensure safe and healthful conditions for persons working at or visiting NASA facilitiesâ?¦." By its very features, including analysis, monitoring, taking decisive action on systems before they become problematic, and thorough documentation, RCM is highly supportive of and an integral part of the NASA safety policy.

7.5.2 Reliability. RCM places great emphasis on improving equipment reliability, principally through the feedback of maintenance experience and equipment condition data to facility planners, designers, facilities maintenance managers, craftspersons, and manufacturers. This information is instrumental in continually upgrading the specifications for equipment to provide increased reliability. The increased reliability that comes from RCM leads to fewer equipment failures and, therefore, greater availability for mission support and lower maintenance costs.

7.5.3 Cost. Due to the initial investment required in obtaining the technological tools, training, and equipment condition baselines, a new RCM program typically results in a short-term increase in maintenance costs. This increase is relatively short lived. The cost of repair decreases as failures are prevented and preventive maintenance tasks are replaced by condition monitoring. The net effect is a reduction of both repair and total maintenance cost. Often, energy savings are also realized from the use of PT&I techniques.

7.5.4 Scheduling. The ability of a condition-monitoring program to forecast maintenance provides time for planning, obtaining replacement parts, and arranging environmental and operating conditions before the maintenance is done. PT&I eliminates unnecessary maintenance performed by a time-scheduled maintenance program, which tends to be driven by the minimum "safe" intervals between maintenance tasks. Additionally, a principal advantage of RCM is that it obtains the maximum use from equipment. With RCM, equipment replacement is based on equipment conditionâ?"not on the calendar. This condition-based approach to maintenance thereby extends the operating life of the properly maintained facility and its equipment.

7.5.5 Efficiency/Productivity. Safety is the primary concern of RCM. The second most important concern is cost-effectiveness. Cost-effectiveness takes into consideration the priority or mission criticality and then matches a level of cost appropriate to that priority. The flexibility of the RCM approach to maintenance ensures that the proper type of maintenance is performed on equipment when it is needed. Maintenance that is not cost effective is identified and not performed.

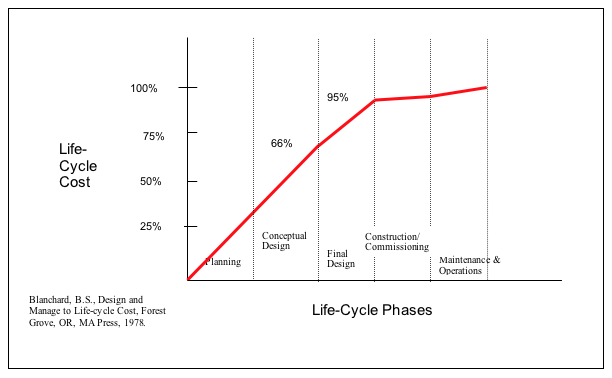

7.6.1 The facilities life cycle is often divided into two broad stages, acquisition (planning, design, construction, and acceptance) and operations. RCM affects all phases of the acquisition and operations stages to some degree, as shown in Table 7-2. Decisions made early in the acquisition cycle profoundly affect the life-cycle cost of a facility. Even though expenditures for plant and equipment may occur later during the acquisition process, their cost is committed at an early stage. As shown conceptually in Figure 7-2, planning (including conceptual design) fixes two-thirds of the facility's overall life-cycle costs. The subsequent design phase determines an additional 29 percent of the life-cycle costs, leaving only about 5 percent of the life-cycle costs that can be impacted by the later phases.

Table 7-2 RCM Facility Life-Cycle Implications

| Life-Cycle Phase | Acquisition Implications | Operations Implications |

| Planning |

Requirements Validation Contract Strategy RCM Implementation Strategy Funding Estimates Construction Equipment (Collateral/R&D) Labor Training Operations A&E Scope of Work BIM |

Requirements Development Modifications Alterations Upgrades A&E Scope of Work Funding Estimates O&M Considerations Annual Cost Labor Spare Parts |

| Design |

A&E Selection Drawings Specifications Acceptance Testing Requirements Commissioning BIM |

A&E Selection Drawings Specifications Acceptance Testing Requirements Commissioning |

| Construction |

Contractor Selection Mobilization Construction Activation (R&D) Commissioning BIM |

Contractor Selection Construction Acceptance Testing Commissioning |

| Acceptance |

Equipment Acceptance and Handoff Establishing Baselines Contract Closeout Commissioning BIM |

Equipment Acceptance and Handoff Establishing Baselines Documentation Commissioning |

| O&M |

BIM Commissioning Assets captured for CMMS RCM Analysis Training/Certification |

BIM Commissioning Assets captured for CMMS RCM Analysis Training/Certification |

Figure 7-2 Stages of Life-Cycle Cost Commitment

7.6.2 The decision to include a facility in the RCM program, including PT&I, is best made during the planning phase. As RCM decisions are made later in the life cycle, it becomes more difficult to achieve the maximum possible benefit from the RCM program.

7.6.3 Even though maintenance is a relatively small portion of the overall life-cycle cost, three to 5 percent of a facility's operating cost, RCM is still capable of introducing significant savings during the O&M phase of a facility's life. Savings of 30- to 50-percent in the annual maintenance budget are often obtained over time through the implementation of a balanced RCM program.

7.7.1 An RCM program includes reactive and proactive maintenance. Refer to the NASA Reliability Centered Maintenance Guide for Facilities and Collateral Equipment for more in-depth information.

7.7.2 Reactive Maintenance. Reactive Maintenance also is referred to as breakdown, repair, or run-to-failure maintenance. When applying this technique, maintenance or equipment repair or replacement occurs only when the deterioration in an equipment's condition causes a functional failure.

7.7.2.1 There is no ability to influence when the failures occur because no (or minimal) action is taken to control or prevent them. When this is the sole type of maintenance practiced, a high percentage of unplanned maintenance activities, high replacement part inventories, and inefficient use of the maintenance effort often result. A purely reactive maintenance program ignores the many opportunities to influence equipment survivability. On the other hand, reactive maintenance can be used effectively when it is performed as a conscious decision based on the results of an RCM analysis that compares the risk and cost of failure with the cost of the maintenance required to mitigate that risk and the cost of failure. For example, periodic maintenance on a standard, inexpensive bathroom fan could not be cost-effective. Typically this type of fan would be run-to-failure and simply replaced at that time, since the cost of maintenance or repair would probably exceed the cost of a replacement fan. Table 7-3 suggests the criteria to be used in determining the priority for repairing or replacing the failed equipment in the reactive maintenance program.

Table 7-3 Reactive Maintenance Priorities

| Priority | ||

| Number | Description | Criteria Based on Consequences of Equipment/System Failure |

| 1 | Emergency | Safety of life or property threatened. Immediate serious impact on mission. |

| 2 | Urgent | Continuous facility operation threatened. Impending serious impact on mission. |

| 3 | Priority | Degrades quality of mission support. Significant and adverse effect on project. |

| 4 | Routine | Redundancy available. Impact on mission insignificant. |

| 5 | Discretionary | Impact on mission negligible. Resources available. |

| 6 | Deferred | Impact on mission negligible. Resources available. |

7.7.3 Proactive Maintenance

7.7.3.1 A proactive maintenance program is the capstone of the RCM philosophy. Proactive maintenance improves maintenance through better design, installation, maintenance procedures, workmanship, and scheduling. The ten most commonly recognized proactive techniques to extend machinery life, described in detail in the NASA Reliability Centered Maintenance Guide for Facilities and Collateral Equipment, are the following:

a. Preventive Maintenance.

b. Predictive Maintenance.

c. Specification for new/rebuilt equipment.

d. Precision rebuild and installation.

e. Failed-part analysis.

f. Root-cause failure analysis.

g. Reliability engineering.

h. Rebuild certification/verification.

i. Age exploration.

j. Recurrence control.

k. Condition Based Maintenance

l. Condition Monitoring

7.7.3.2 The characteristics of proactive maintenance are the following:

a. It uses feedback and communications to ensure that changes in design or procedures are promptly made available to designers and managers.

b. It employs a life-cycle view of maintenance and supporting functions.

c. It ensures that nothing affecting maintenance occurs in isolation.

d. It employs a continuous process of improvement.

e. It optimizes and tailors maintenance techniques and technologies to each application.

f. It integrates functions (that support maintenance) into maintenance program planning.

g. It uses root-cause failure analysis and predictive analysis to maximize maintenance effectiveness.

h. It adopts an ultimate goal of on-going equipment maintenance.

i. It periodically evaluates the technical content and performance interval of maintenance tasks (PM and PT&I).

7.7.3.3 A successful maintainability program will have the following attributes:

a. Corporate commitment.

b. Program support.

c. Maintainability planning.

d. Maintainability implementation.

e. Program updating.

7.7.3.4 An additional critical step in implementing an effective proactive maintenance program is the design for maintainability process. Design for maintainability was a NASA-sponsored research project conducted by the Construction Industry Institute. Design for maintainability integrates facility operations and maintenance knowledge and experience at an early stage in the project-delivery process. Incorporating maintainability concepts, including RCM, early in the life of a project, where influence potential is high, will result in the principal benefits of less rework, smoother startup and turnover, and less costly maintenance after project turnover. Design for maintainability represents a method to formally incorporate proactive maintenance into construction projects. It will allow active participation of operation and maintenance staff in determining facility project design requirements and ensure these requirements are satisfied. Additional information on this concept is available from Construction Industry Institute publications.

7.7.3.5 The design for maintainability model process has six major milestones:

a. Management commitment to maintainability. Demonstrated through commitment of resources, development policies, and designating a maintainability champion.

b. Establishing a maintainability program. Demonstrated through development of a maintainability staff, procedures, and a lessons-learned database.

c. Obtaining maintainability capabilities. Demonstrated by establishing project-level maintainability responsibility and developing resources for project maintainability reviews.

d. Planning maintainability implementation. Demonstrated by forming project cross-functional teams, defining maintenance strategies and maintainability goals, and integrating appropriate RCM technology.

e. Implementing maintainability. Demonstrated by conducting project maintainability meetings, applying maintainability concepts to design and construction, providing documentation, and conducting maintenance training.

f. Updating the maintainability program. Demonstrated by evaluating program effectiveness and updating the process in the lessons-learned database.

7.7.3.6 Within the ideal process milestones and the success attributes, maintainability shall be accomplished through several different approaches applied individually or in combination. These approaches are:

a. Standard design practice.

b. Contract specifications, such as Specification-kept-intact (SPECSINTACT), having appropriate maintainability and RCM clauses included.

c. Cross-functional project teams.

d. Pilot maintainability programs.

e. Integration of maintainability into existing project programs and processes.

f. Formal maintainability program.

g. Comprehensive tracking of lessons learned.

7.7.3.7 In summary, design for maintainability is the first step of an effective maintenance program, linking proactive maintenance and RCM goals to the design and construction process. If adequate measures for cost-effective maintainability are not integrated into the design and construction phases of a project, the risk increases that reliability will be adversely impacted and total life-cycle costs increase significantly. Appropriate levels of maintainability seldom occur by chance. It requires upfront planning, setting objectives, disciplined design implementation, and feedback from prior projects. It is vital to identify critical maintainability and reliability issues and integrate them into facility project designs to achieve long-term facility owning and operating benefits.

7.7.4 Preventive Maintenance. PM consists of regularly scheduled inspection, adjustments, cleaning, lubrication, parts replacement, calibration, and repair of components and equipment. It is performed without regard to equipment condition. PM schedules periodic inspection and maintenance at predefined intervals in an attempt to reduce equipment failures for susceptible equipment. As equipment ages, the frequency and number of checkpoints may need to be reevaluated using the age exploration process. This is a process that uses PT&I and other methods to extend the period between PM tasks while maintaining equipment condition. This process can result in substantial maintenance savings. These savings are dependent on the PM intervals set, which can result in a significant decrease in inspection and routine maintenance. However, it should also reduce the frequency and seriousness of unplanned machine failures for components with defined, age-related wear patterns.

7.7.4.1 Traditional PM is keyed to failure rates and times between failures. It assumes that these variables can be determined statistically. Therefore, a part due for failure can be replaced before it fails. PM assumes that the overhaul of machinery by disassembly and replacement of worn parts restores the machine to like-new condition with no harmful side effects and that the new components are less likely to fail than the old components of the same design.

7.7.4.2 Failure rate, or its reciprocal, mean-time-between-failures, is often used as a guide to establishing the interval at which maintenance tasks should be performed. The major weakness in the application is that failure-rate data determines only the average failure rate. In reality, failures are equally likely to occur at random times and with a frequency unrelated to the average failure rate. For some items, failure is not related to age, and consequently, timed maintenance can often result in unnecessary maintenance. PM can be costly and ineffective when it is the sole type of maintenance practiced.

7.7.5 Predictive Testing and Inspection.

7.7.5.1 PT&I, also known as predictive maintenance or condition monitoring, uses primarily nonintrusive testing techniques, visual inspection, and performance data to assess machinery condition. It replaces arbitrarily timed maintenance tasks with maintenance that is scheduled only when warranted by equipment condition. Continuing analysis of equipment condition-monitoring data allows for the planning and scheduling of maintenance or repairs in advance of catastrophic and functional failure. Collected PT&I data is used for trend analysis, pattern recognition, data comparison, tests against limits and ranges, correlation of multiple technologies, and statistical process analysis to determine the condition of the equipment and to identify the precursors of failure. PT&I does not lend itself to all types of equipment or possible failure modes and, therefore, should not be the sole type of maintenance practiced.

7.7.5.2 A variety of PT&I methods are used to assess the condition of systems and equipment. These technologies include intrusive and nonintrusive methods as well as the use of process parameters to determine overall equipment condition. The data acquired permits an assessment of the system or equipment performance degradation from the as-designed condition. The most common PT&I technologies, described in greater detail in Appendix F and the NASA Reliability Centered Maintenance Guide for Equipment and Collateral Equipment, are the following:

a. Vibration Analysis.

b. Lubricant and Wear Particle Analysis.

c. Thermal Imaging and Temperature Measurement.

d. Passive (Airborne) Ultrasonics.

e. Electrical Testing and Motor Current Analysis.

f. Flow Measurement and Leak Detection.

g. Valve Operation.

h. Corrosion Monitoring.

i. Process Parameters.

j. Visual Observations.

7.7.6 Condition Based Maintenance (CBM) is maintenance when the need arises. In CBM, the performance of the asset is generally continuously monitored during operation and results are compared to asset baselines. Maintenance is performed after one or more indicators show that equipment is going to fail or that equipment performance is deteriorating. CBM is implemented to improve maintenance agility and responsiveness, increase operational availability, and reduce life cycle total ownership cost.

7.7.6.1 CBM is implemented on assets that are large, very expensive, operate at high energy, are costly to tear down to maintain, and have high or very high Risk Assessment Codes. Investment in several different real time monitors of each asset is required. The level of investment depends on the Risk Assessment Code of the asset. Sufficient monitoring is required to provide decision-making information to knowledgeable system managers so that they will operate high-energy assets safely at low risk and maintain those assets when necessary.

7.8.1 In addition to their applicability during the operations and maintenance phase of equipment life cycles, RCM principles should be used in performing the FCAs and in preparing the AWP; during facilities planning, design, new construction, modification, equipment procurement; in the preparation of architect and engineering (A&E), construction, equipment procurement, and maintenance and operation contracts; in the acceptance testing of new or major repaired equipment by the contractor during the acceptance process; and in the quality assurance of performance-based contracts. Appropriate RCM clauses and criteria shall be included in all Requests for Proposals, Requests for Quotations (RFQs), and in the contracts themselves.

7.8.2 Facilities Condition Assessment. (See also Chapters 4, Annual Work Plan, and 9, Deferred Maintenance.) RCM is valuable during the continuous FCA process. Individual system reliability and O&M costs and numbers of TCs, plotted over the equipment's service life, can be tracked by the CMMS. Equipment condition relative to other similar equipment can be tracked by reviewing the PT&I data and can be statistically trended in a spreadsheet. Similarly, other indices, such as PT&I alarms and equipment availability, can be tracked. The sum of all of this data will result in a rank ordering of the equipment in terms of condition, availability, and cost to maintain the function.

7.8.3 Annual Work Plan. (See also Chapter 4, Annual Work Plan, for a more detailed discussion.) RCM principles, and particularly PM and PT&I, are integrated into the Center's maintenance program through the Annual- and 5-Year Work Plans. These are required to develop PM and PT&I funding requirements for the next 5 years, including all labor, parts, materials, and special tools. RCM will identify the most effective maintenance, in terms of retaining the highest reliability at the lowest cost, and include criticality codes based on mission support, condition code, specific inspections and maintenance tasks to be performed, equipment parameters, the estimated resources required, and specific instructions for obtaining condition assessment information as part of each maintainable collateral equipment PM/PT&I.

7.8.4 Deferred Maintenance. (See also Chapter 9, Deferred Maintenance, for a more detailed discussion.) Facilities maintenance within NASA is crucial in ensuring facility availability for critical missions throughout the Agency and in NASA's stewardship of the Government facilities with which it is entrusted. The effect of reduced maintenance is not always noticeable immediately, and therefore, it is essential that Centers have sufficient management information available to plan long- and short-term maintenance requirements properly, recognize adverse funding trends, and be able to articulate the effects of reduced maintenance on facility availability and the mission. After the RCM process is used to identify facility and equipment availability and condition deficiencies, the DM identifies to higher authorities, i.e., OMB and Congress, unfunded facilities maintenance work for those items necessary to support the Center mission and the consequences of inadequate funding.

7.8.5 Specifications-Kept-Intact (SPECSINTACT)

7.8.5.1 Early in the planning of a new facility, consideration shall be given to the extent RCM analysis and PT&I techniques will be used to maintain the facility and equipment. The fundamental determination is the amount of built-in condition monitoring, data transfer, and sensor connections to be used. It is more economical to install this monitoring equipment and connection cabling during construction than later. Planning, designing, and building-in the condition monitoring capability ensures that it will be available for the units to be monitored. Continuously monitored equipment tied into performance analyzers permits the monitoring of its function and signs of any degradation. Installed systems also reduce labor requirements relative to obtaining the data manually.

7.8.5.2 NASA has integrated RCM principles into its standard construction specifications, SPECSINTACT. The emphasis is to design new equipment with a high degree of reliability, at the lowest reasonable cost, thereby, achieving improved maintainability and ease of monitoring. Maintainability and monitoring factors that should be considered by the designer include the following:

a. Access. Equipment, its components, and facilities should be accessible for maintenance. There should be clear access to collect equipment-condition data with portable data loggers or fluid sample bottles.

b. Material. Materials shall be chosen for durability, ease of maintenance, availability, and value.

c. Standardization. Use of special or one-of-a-kind materials, fittings, or fixtures is to be minimized, and the use of common equipment component parts maximized. Standard equipment that can have multiple uses should be selected, where feasible.

d. Quantitative Maintenance Goals. Quantitative measures of maintenance (such as mean-time-between-maintenance (MTBM) and maintenance downtime) should be used during design to set maintainability goals.

e. On-line Data Collection. Installed data-collection sensors and links may be justified for high-priority, high-cost equipment or inaccessible equipment.

f. Management Indicators. Management indicators and the analysis method should be incorporated into the system design. Often, the performance parameters monitored for equipment or system control can be used to monitor equipment condition.

g. Performance Measures. RCM performance measures such as operating time or equipment loading are directly equipment related. The data to be used and the collection method are incorporated into the system design.

7.8.6 Acceptance. (See also Chapter 8, Reliability Centered Building and Equipment Acceptance, for a more detailed discussion.) In today's tight budget environment for facilities operations and maintenance, there is great advantage to NASA in using the construction contractor's quality control function, prior to the contractor's receipt of final payment and exit from the job site, to perform noninvasive diagnostic tests (PT&I) to verify that there are no latent manufacturing defects and the quality of the installation of newly installed equipment.

7.8.7 Performance-based Contract Monitoring. (See also Chapter 12, Contract Support, for a more detailed discussion.) Performance-based contract and outcome monitoring require the contractor to meet specific standards of performance. These are often based on metrics and indicators that are derived from RCM principles and obtained through PT&I technologies. Percentage availability, for example, is a performance metric that is compared to a standard set by the Center based on baseline data obtained at the time of equipment acceptance or during RCM analysis. Further, the degree of QA required of the Government is dependent not only on the contractor's performance, but also on the RCM criticality codes applied to each facility and equipment. PT&I techniques may be prescribed in the Government's formal QA Plan as methods used to inspect the contractor's work and RCM analysis may be used by the QAE to observe overall trends. For example, trends identifying increased TCs or downtime for specific units of equipment may be indicative of a lack of preventive maintenance that the contractor is obligated to perform.

| TOC | Change History | Preface | Chapter1 | Chapter2 | Chapter3 | Chapter4 | Chapter5 | Chapter6 | Chapter7 | Chapter8 | Chapter9 | Chapter10 | Chapter11 | Chapter12 | AppendixA | AppendixB | AppendixC | AppendixD | AppendixE | AppendixF | AppendixG | AppendixH | AppendixI | ALL | |

| | NODIS Library | Program Management(8000s) | Search | |

This document does not bind the public, except as authorized by law or as incorporated into a contract. This document is uncontrolled when printed. Check the NASA Online Directives Information System (NODIS) Library to verify that this is the correct version before use: https://nodis3.gsfc.nasa.gov.